Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

HISTORY OF FORCE MEASUREMENT

HISTORY OF FORCE MEASUREMENT

- Force Measurement IMADA

- ABOUT IMADA

- HISTORY OF FORCE MEASUREMENT

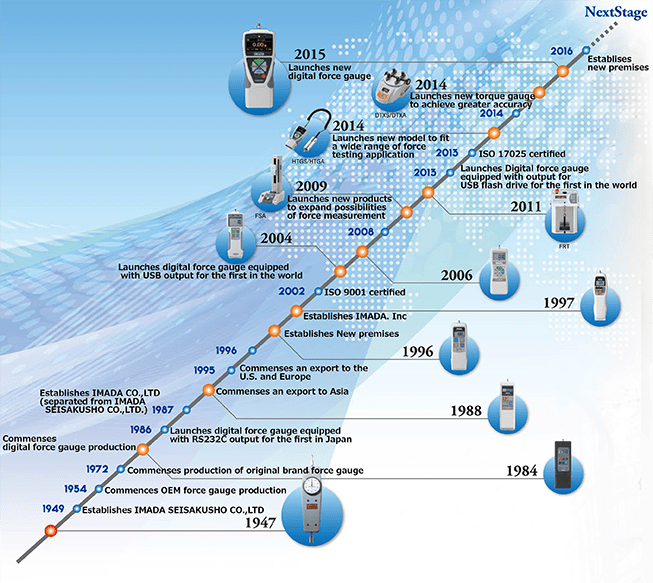

70 year-old history of IMADA

First Chapter of IMADA (unfolded in 1947)

In 1940s, force gauges were hardly available in Japan. The first chapter began in 1947, when the company's predecessor, who was then running a small factory, decided to challenge himself, and to materialize force gauges for his customer. He developed several as custom-made. He did not halt and in fact continued improving the quality. It took another 6 years, when we received the first three orders of mass produced force gauges in 1954.

Secrets of IMADA’s mechanical force gauge >

Leaps and Bounds - From Mechanical to Digital

While IMADA's mechanical force gauges were gaining popularity, we received requests from customers asking for digital force gauge. As we highly valued customers' inquires and in particular, suggestions, we unrolled the development of digital force gauges. After a few hundreds of trials and errors, the very first digital force gauge was commercially available in 1984. By carefully reviewing customer inquires, we recognized the customer needs to output measurement data acquired by digital force gauges. It took another two years before we introduced the first RS232C output function equipped model in 1986.

History of IMADA’s digital force gauges >

Another Leap Forward - Spin off of Force Gauge division, Incorporated, and Global Footprint

In order to reach worldwide customers, and to expand IMADA's global footprint in handheld force gauges, IMADA CO., Ltd. was established in 1987. It wasn't the smoothest ride, and in fact, we began by the former CEO hand-carrying several force gauges, and jumping on airplane, even without business appointments. Upon arriving airports, he looked for local interpreter, and tried arranging meetings. The walk-in sales continued and expanded from Asia, Europe, and then Americas. As the regional coverages widened, so did orders.

Redefine IMADA's reason for existence - from force gauge manufacturer to force measurement specialist

Customers use tool not because they need tool but they need performance and function. And right ones.

Fully realizing the fundamental, and in order to materialize ever-expanding customer needs, IMADA has expanded the product spectrum.

-various attachments and motorized stands for more accurate measurement results

-units that can measure displacement as well as force

-torque meters to measure rotational force

-units for medical use

-specialized measuring instruments for the food industry

Quest for the genuine customer orientation

IMADA firmly believes that the evolution of the company and the innovation of our products over the past half century is the fruit of our strong desire to meet the measurement needs of all our customers and our unrelenting efforts to listen to them. At a time when dramatic changes in the environment and technological evolution tend to separate us from our customers, we want to be even more customer-oriented. We expand customer department, diversify our digital and analog contact points with customers throughout the company, and introduce and develop new services. Introduction of Force Channel, a new customer community website and IMADA Connected, which enables IMADA equipment to continuously evolve are just a few examples. We will continue to improve the value of our services by incorporating the voices of our customers.

For future growth

In order to further excel the strengths, we have accelerated our efforts to grow ourselves in tangible and intangible manners. In tangible aspect, we introduced "Personnel Analysis Chart" and "Career Path Flow" and at the same time, have been enhancing the internal training. In intangible aspect, we have also evolved in the "facilities" aspect, such as obtaining ISO/IEC17025:2005 accreditation, International Standard for accrediting calibration laboratories. We also completing the construction and moved to new office premise.

In addition, and in intangible aspect, we highly cherish technology and put equal efforts to evolve technological capability. Obtaining Patent through joint research with the University of Tokyo, and developing the world's first technology (i.e., force gauge equipped with a function to directly record continuous data on a USB memory stick), are just a few example. We are fully determined to accelerate our growth in the three areas of "people," "facility," and "technology", and we do so without being satisfied with our past progress.

IMADA’s personnel system >

IMADA’s calibration lab >

Collaborative R&D with reserch institutes >

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

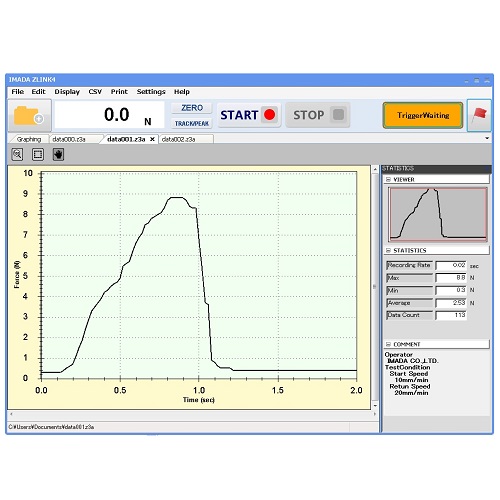

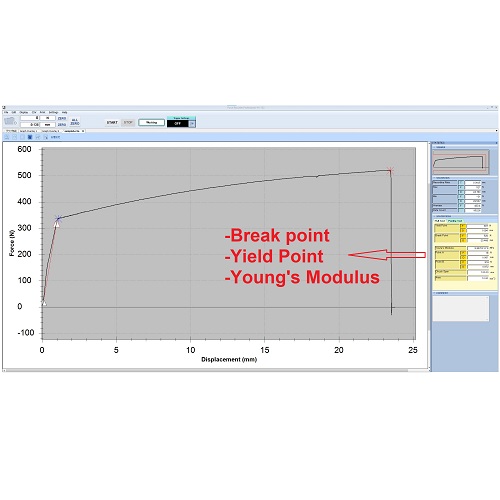

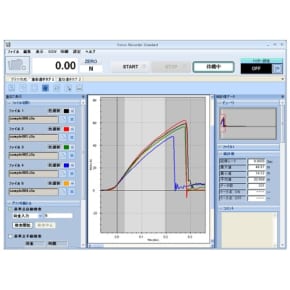

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

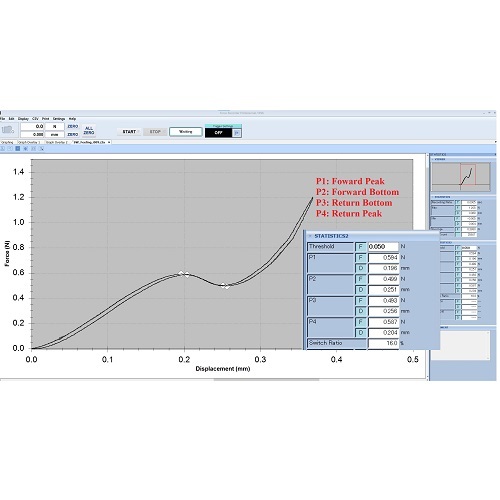

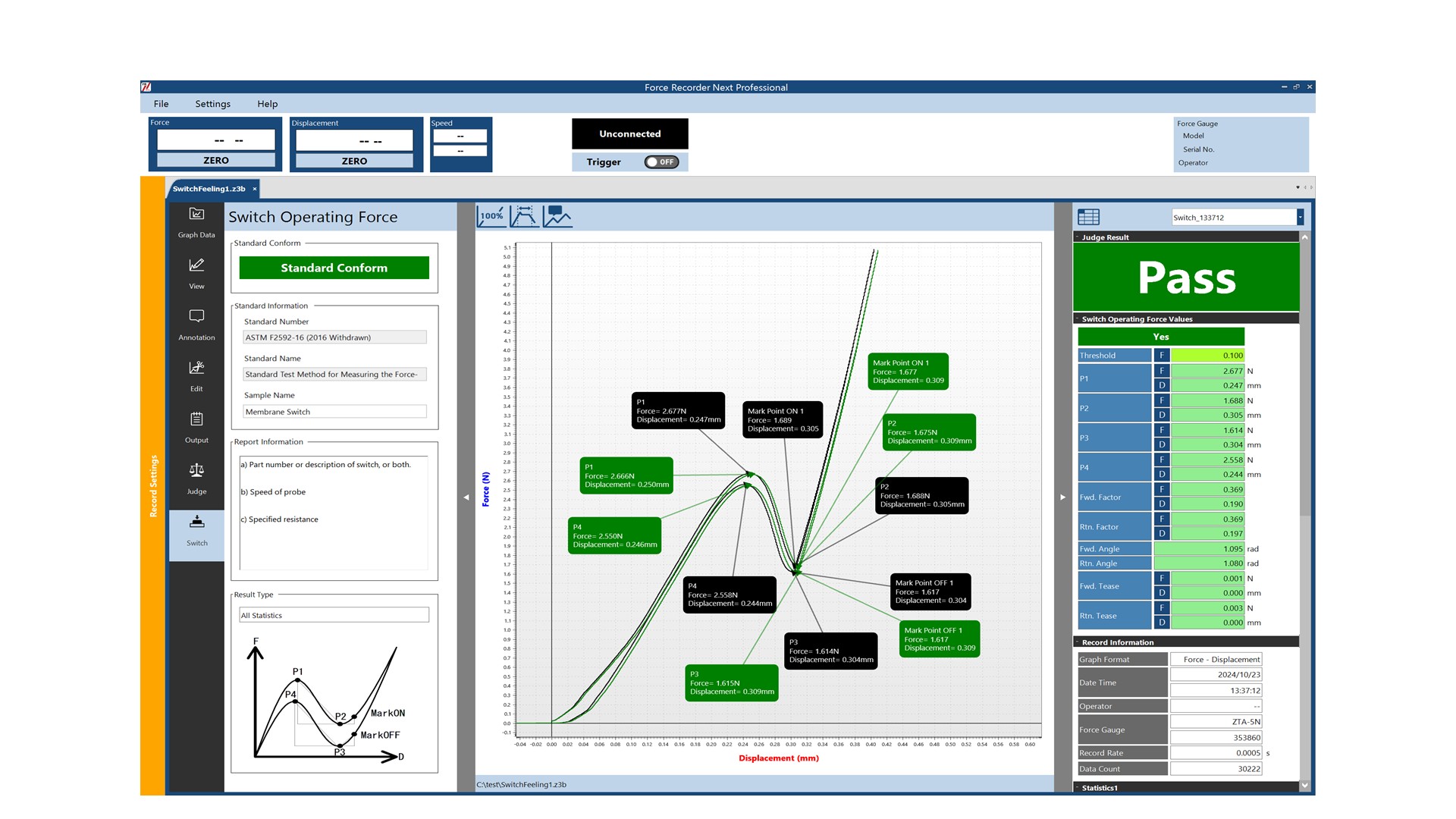

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

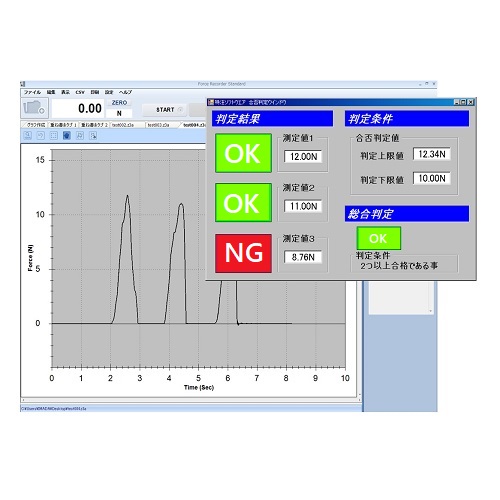

Multi-Peak Extraction Function

Multi-Peak Extraction Function

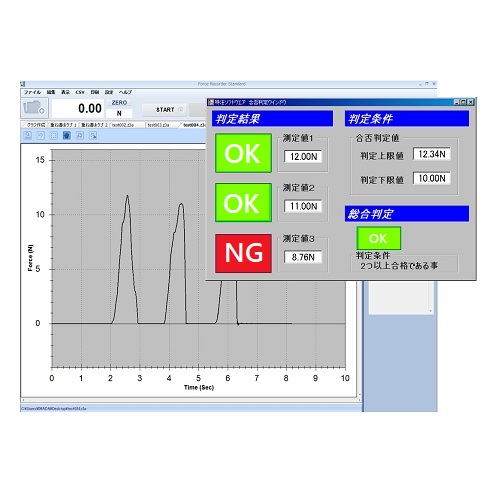

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

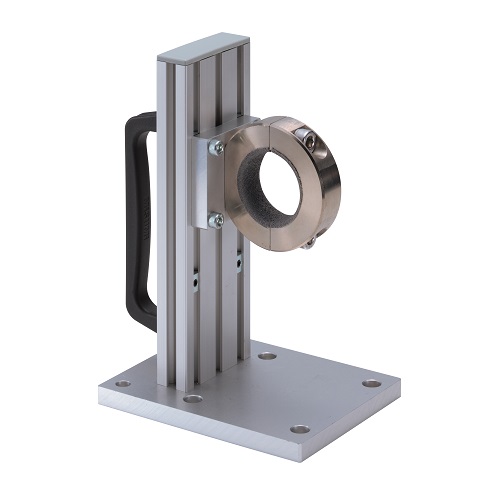

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

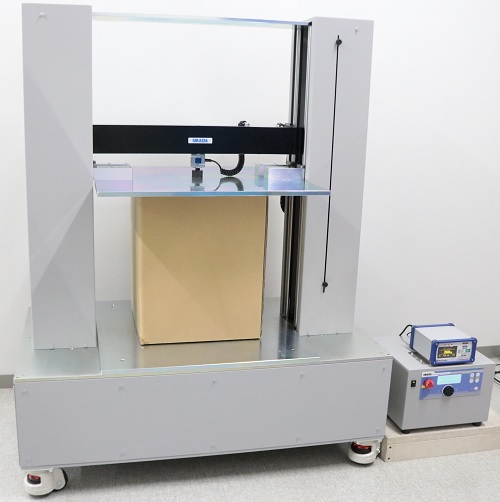

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

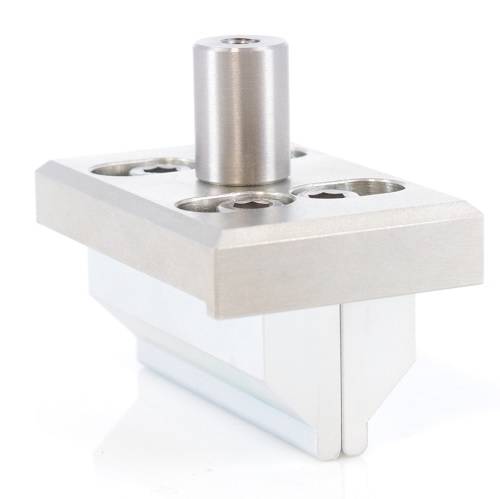

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

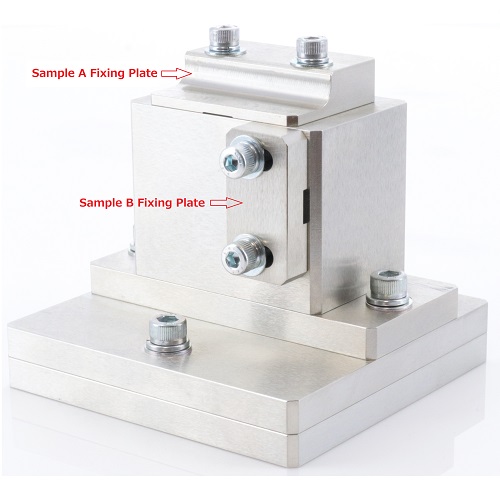

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

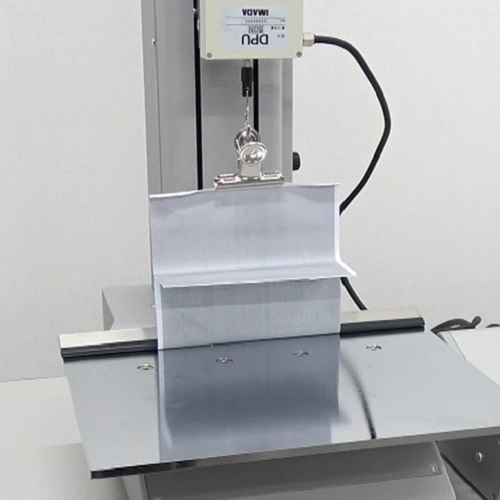

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

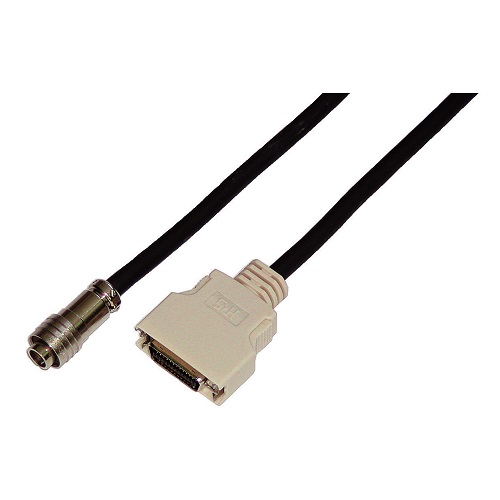

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

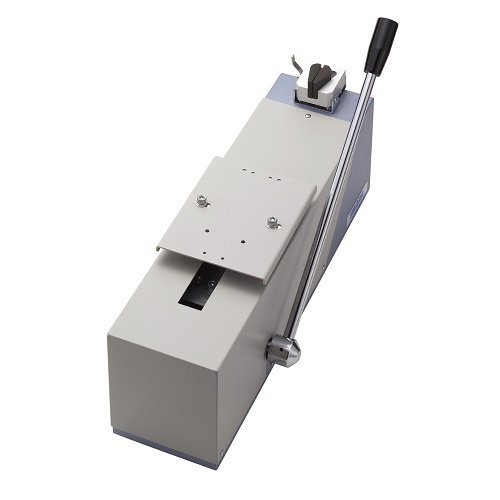

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

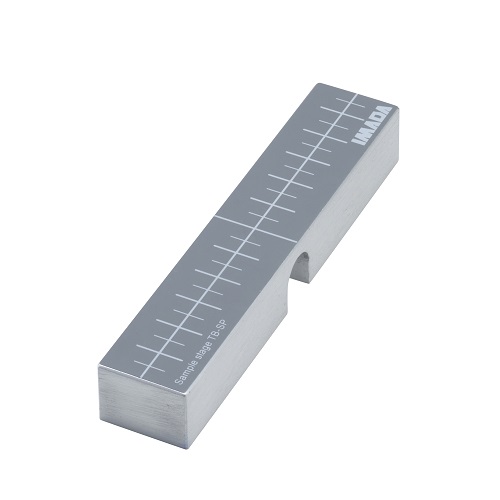

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

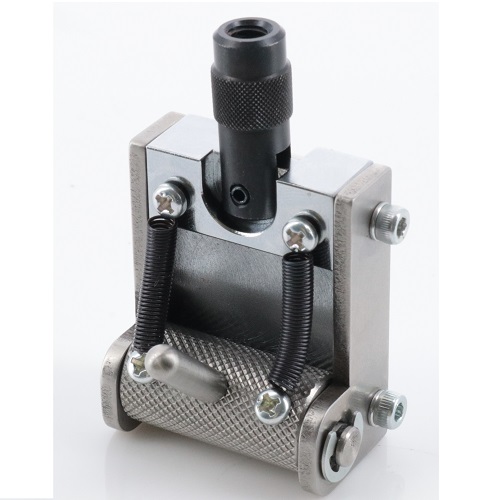

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

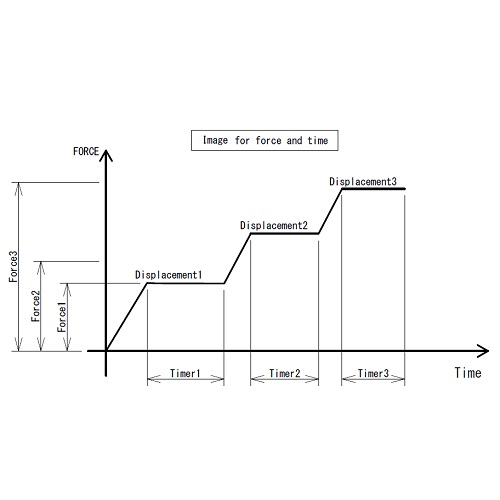

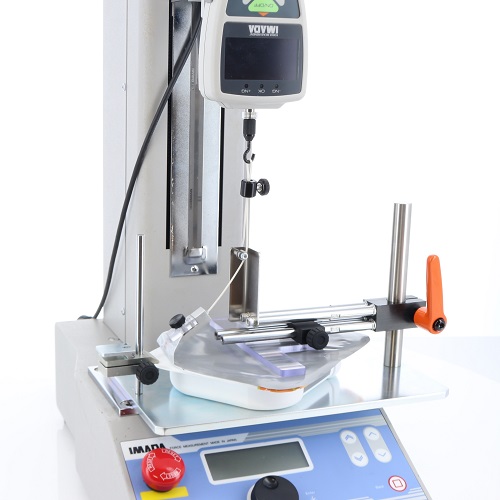

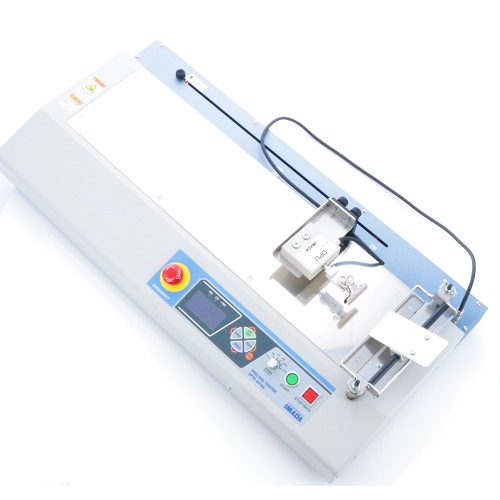

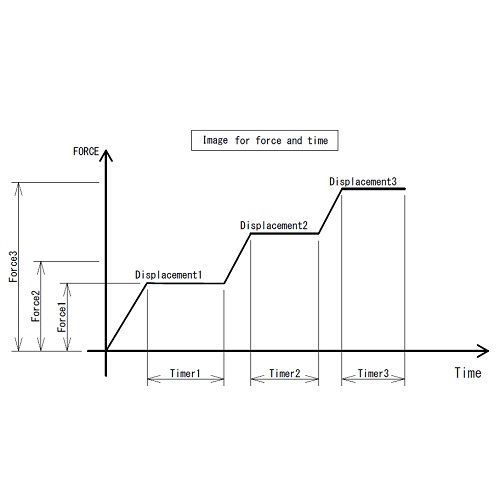

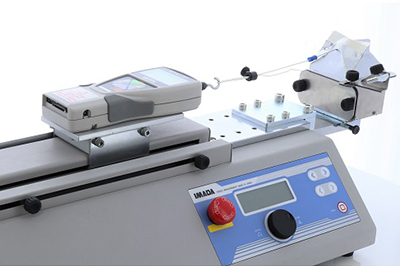

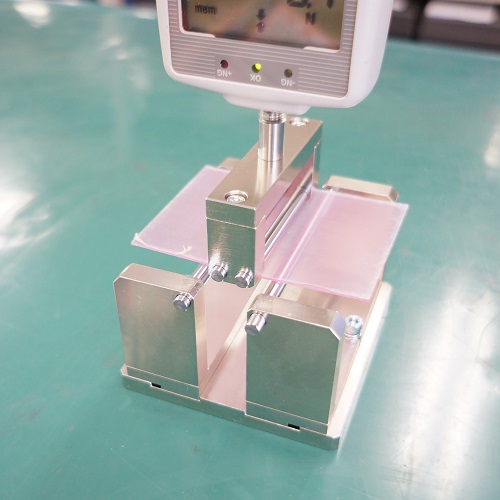

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

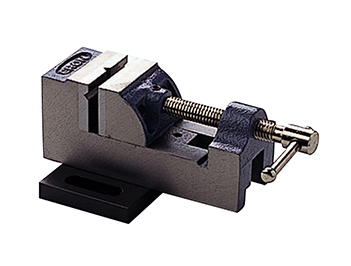

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

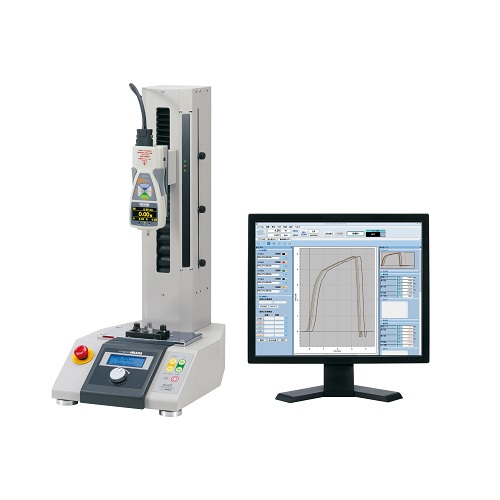

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

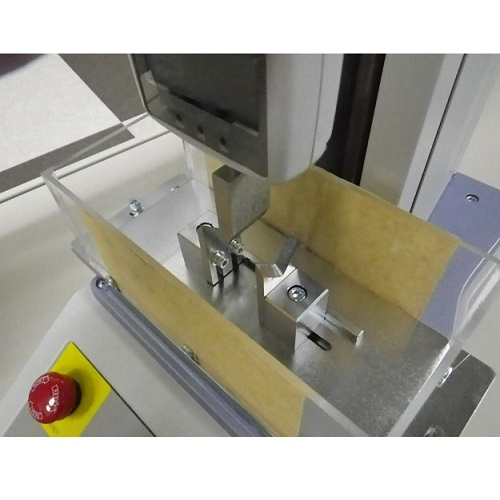

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

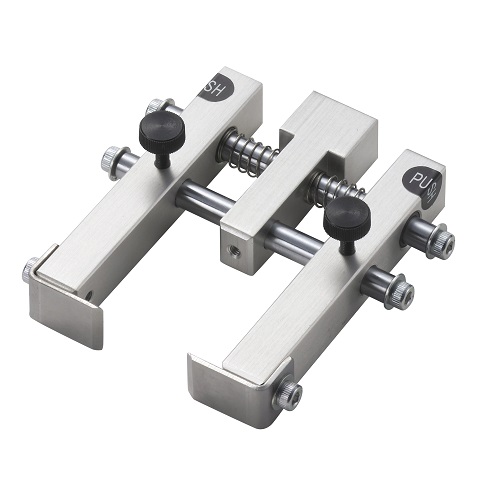

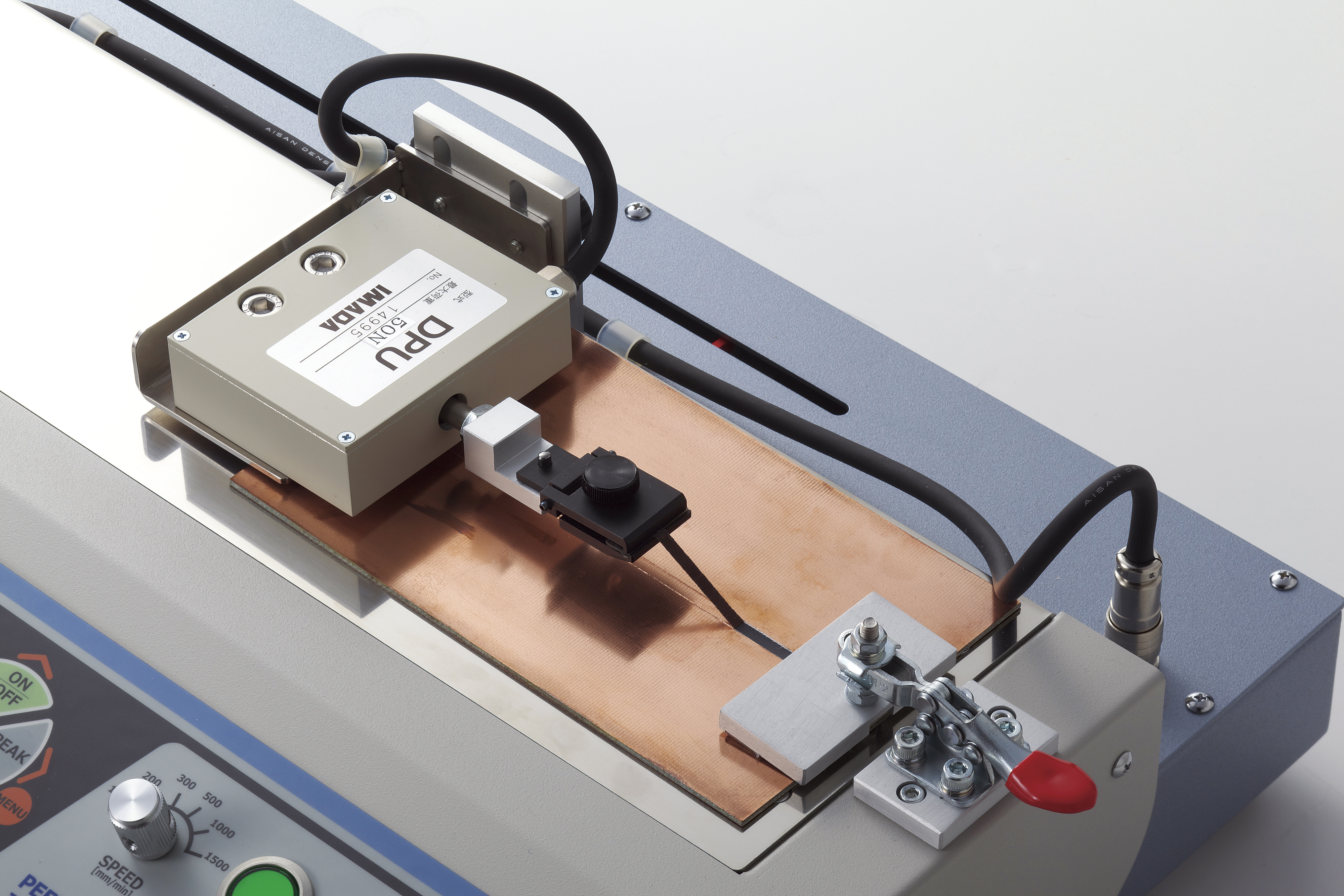

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)