Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

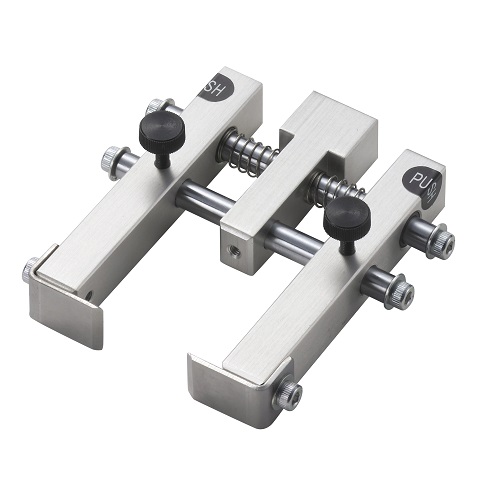

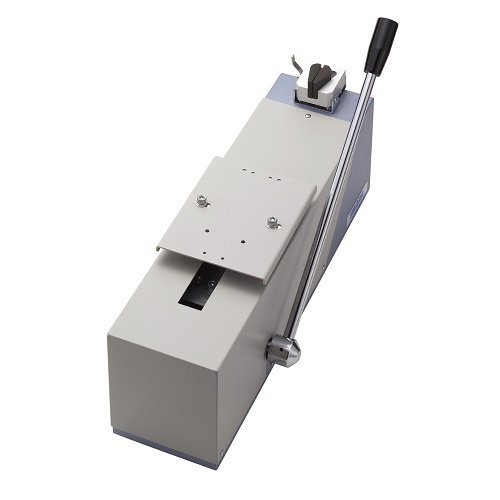

Rotary Wire Terminal Fixture

FW-12/PW-4

Description Add to favorites

Feature

- Designed for tension strength testing of crimped terminal

- Enhances measurement efficiency by simply rotating the wheel to set samples of different sizes

- 2 models available: for general terminals (FW-12) and for round terminals (PW-4)

- Complies with the corresponding part of IEC and JIS standard

Relevant Industrial Standards

IEC 60512-16-4 [ 2008 ] [Connectors for electronic equipment-Tests andmeasurements-Part 16-4: Mechanical tests on contacts and terminations-Test16d: Tensile strength (crimped connections)] (corresponding part only)

JIS C2805 [ 2010 ] [Crimp-type terminal lugs for copper conductors] (corresponding part only)

JIS C5402-16-4 [ 2012 ] [Connectors for electronic equipment-Tests andmeasurements-Part 16-4: Mechanical tests on contacts and terminations-Test16d: Tensile strength (crimped connections)] (corresponding part only)

Relevant Information and Materials

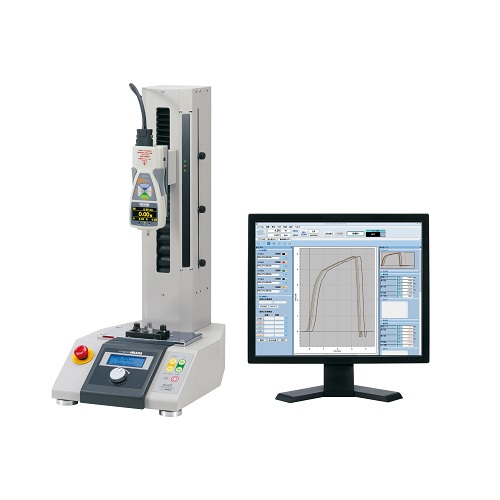

Example of Product Configuration

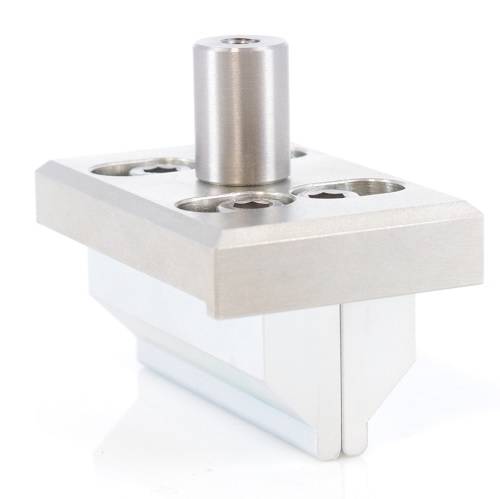

FW-12

Features

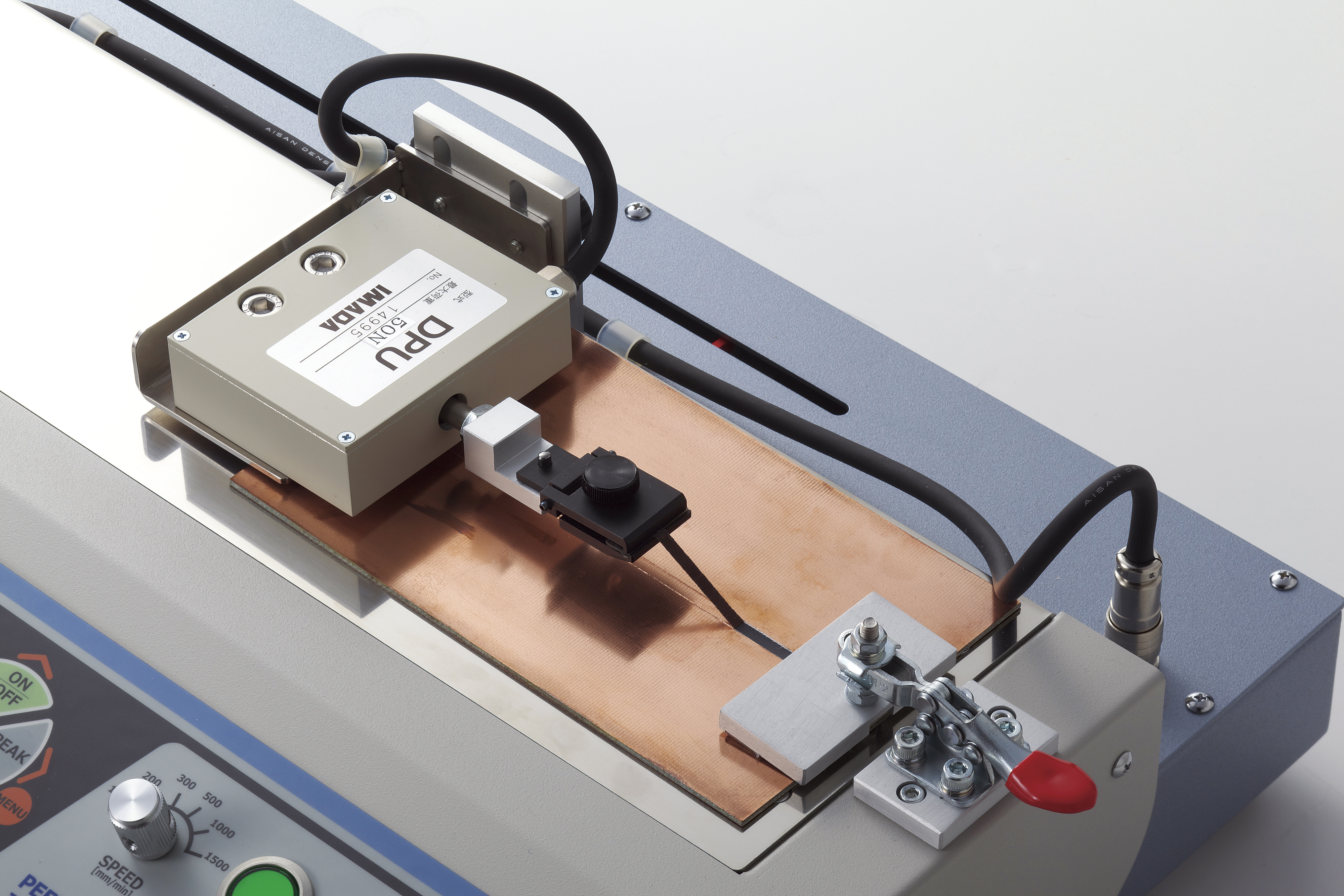

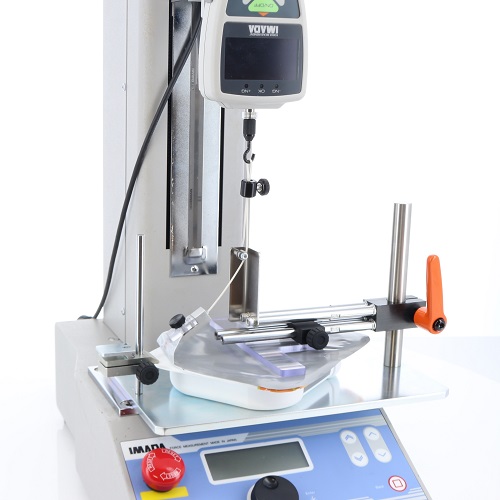

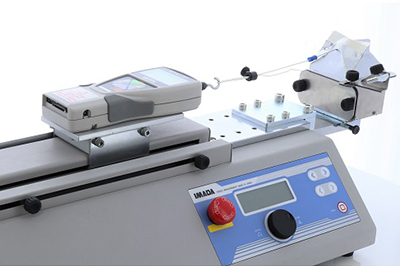

This testing system determines the tensile strength of crimped terminals.

It offers a simple solution of tensile test up to 1000N.

FW-12 accommodates a wide range of wire diameters. You only have to rotate the wheel to the desired size, and hook the terminal to it.

inquiry number

1F2001A

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force Gauge

DST-1000N

1

Motorized Test Stand

MX-1000N

1

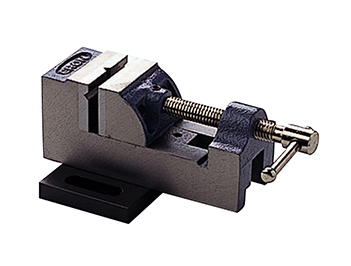

Optional Attachment

FW-12

1

Optional Attachment

GP-30

1

Cautions

You have to hook a crimped terminal to FW-12 as a preperation for the test, therefore, a narrow crimped terminal (such as rod crimp terminal) might not be hooked/tested appropriately.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

Features

This testing system determines the tensile strength of crimped terminals.

It offers a functional & versatile solution of tensile test up to 1000N.

FW-12 accommodates a wide range of wire diameters. You only have to rotate the wheel to the desired size, and hook the terminal to it.

inquiry number

1F2001B

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force Gauge

ZTS-1000N

1

Motorized Test Stand

MX2-1000N

1

Optional Attachment

FW-12

1

Optional Attachment

GP-30

1

Optional Cable

CB-528

1

Relevant Industrial Standards

JIS C 2805 [ 2010 ] [Crimp-type terminal lugs for copper conductors] (corresponding part only)

JIS C 5402-16-4 [ 2012 ] [Connectors for electronic equipment - Tests and measurements - Part 16-4: Mechanical tests on contacts and terminations - Test 16d: Tensile strength (crimped connections)] (corresponding part only)

IEC 60512-16-4 [ 2008 ] [Connectors for electronic equipment - Tests and measurements - Part 16-4: Mechanical tests on contacts and terminations - Test 16d: Tensile strength (crimped connections)] (corresponding part only)

Cautions

You have to hook a crimped terminal to FW-12 as a preparation for the test, therefore, a narrow crimped terminal (such as rod crimp terminal) might not be hooked/tested appropriately.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

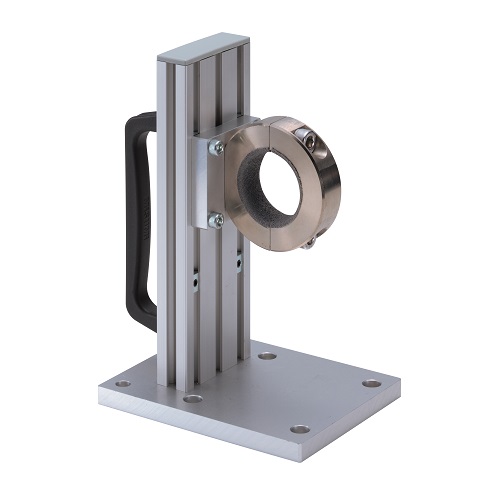

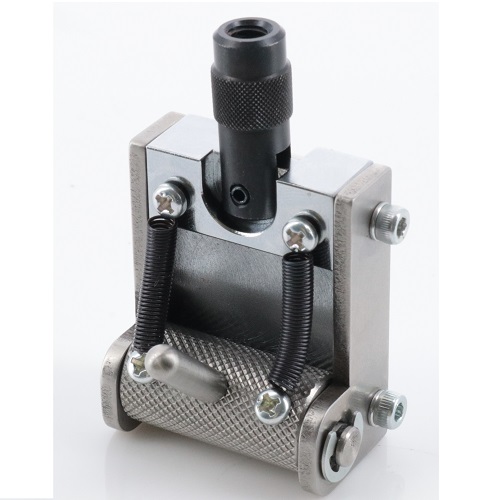

PW-4

Features

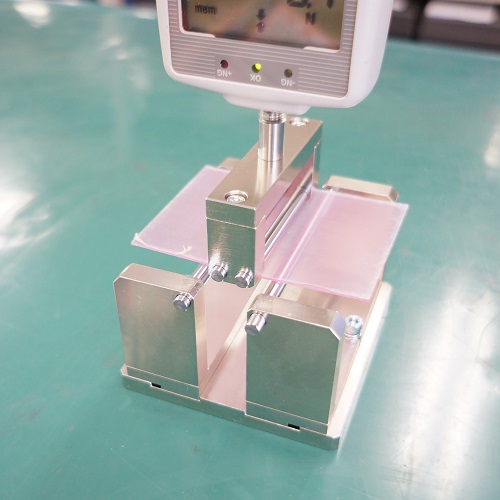

This testing system determines the tensile strength of round crimped terminals.

It offers a simple solution of tensile test up to 1000N.

PW-4 accommodates a wide range of wire diameters. You only have to rotate the wheel to the desired size, and hook the terminal to it.

inquiry number

1P2002A

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force Gauge

DST-1000N

1

Motorized Test Stand

MX-1000N

1

Optional Attachment

PW-4

1

Optional Attachment

GP-30

1

Cautions

Hook a round terminal to the pin as a perperaton for the test.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

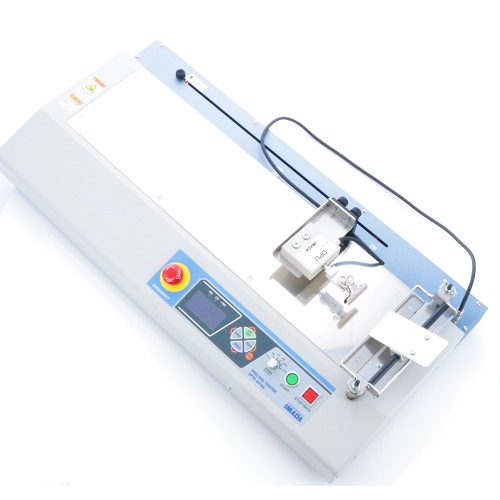

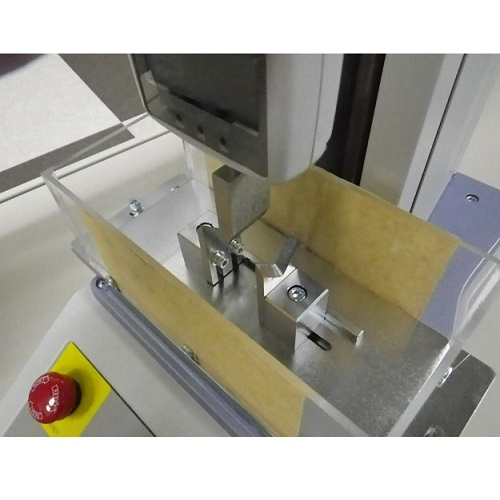

Features

This testing system determines the tensile strength of round crimped terminals.

It offers a functional & versatile solution of tensile test up to 1000N.

PW-4 accommodates a wide range of wire diameters. You only have to rotate the wheel to the desired size, and hook the terminal to it.

inquiry number

1P2002B

Present the “inquiry number” below when you contact us, for prompt assistance.

Product used

Digital Force Gauge

ZTS-1000N

1

Motorized Test Stand

MX2-1000N

1

Optional Attachment

PW-4

1

Optional Attachment

GP-30

1

Optional Cable

CB-528

1

Relevant Industrial Standards

JIS C 2805 [ 2010 ] [Crimp-type terminal lugs for copper conductors] (corresponding part only)

Cautions

Hook a round terminal to the pin as a perpetration for the test.

Refer to specifications of each product for details.

Product configuration varies depending on the shape and characteristic of the sample, and measurement conditions.

The recommended capacity of measurement instruments varies depending on the expected force to be loaded.

Relevant Products

Measurement Example Videos

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

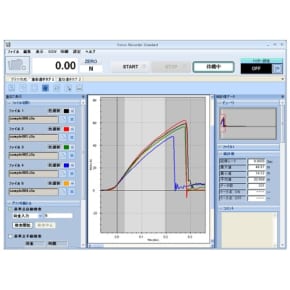

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

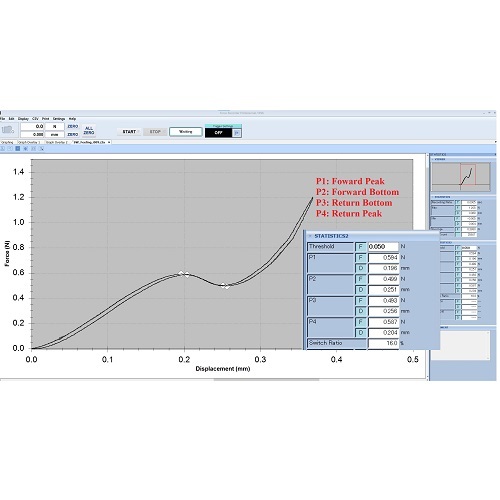

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

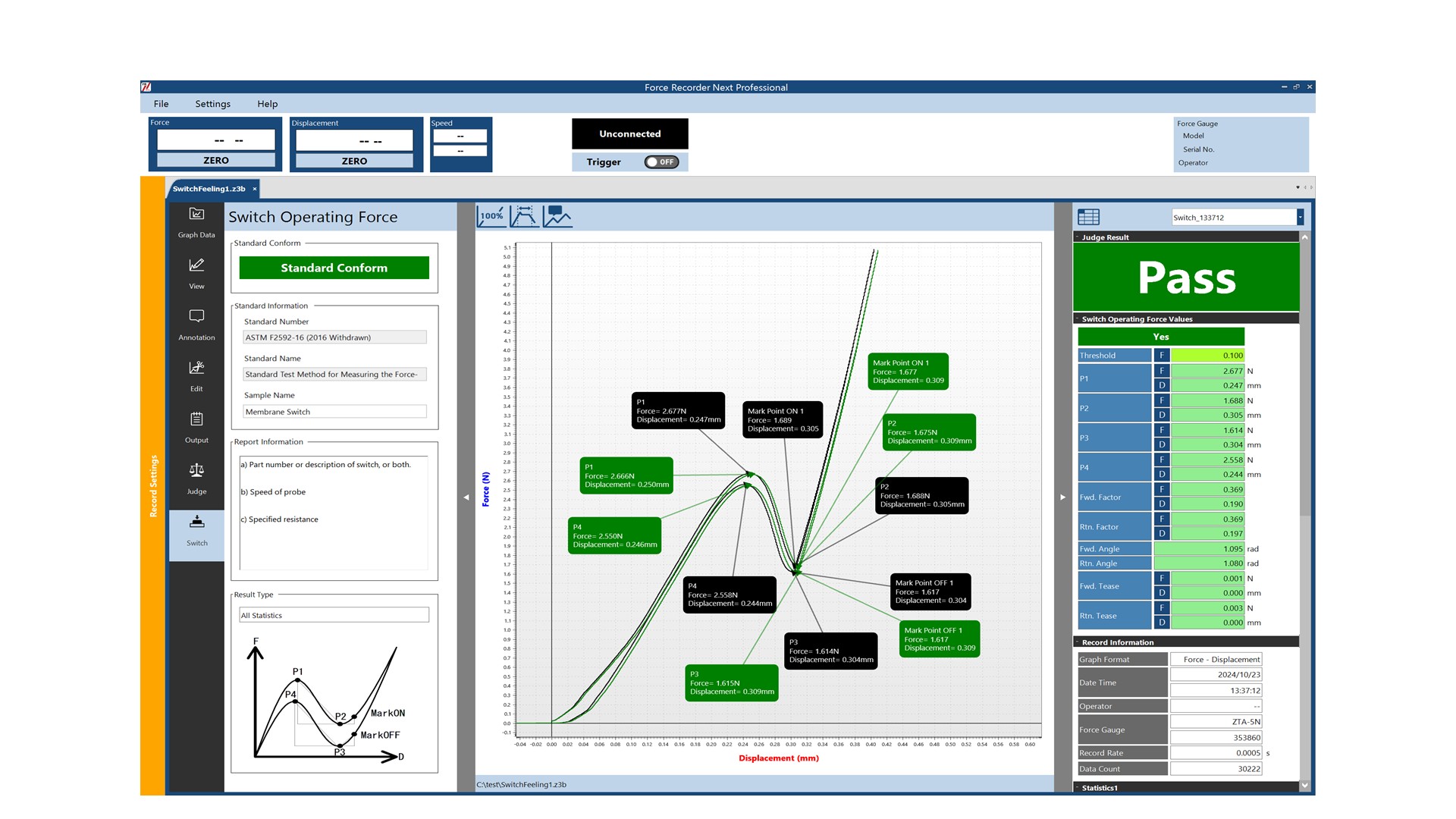

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

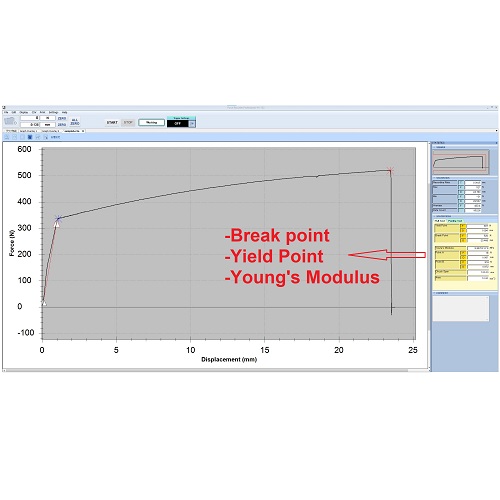

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

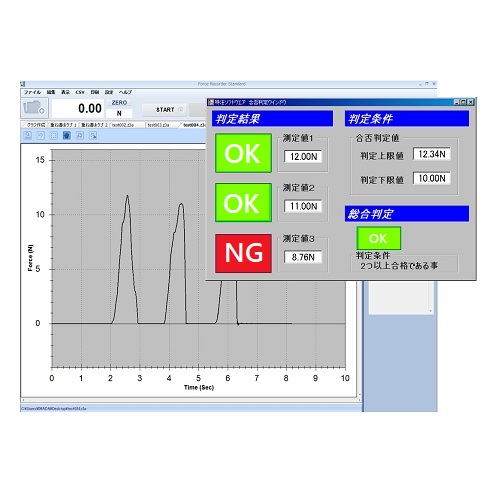

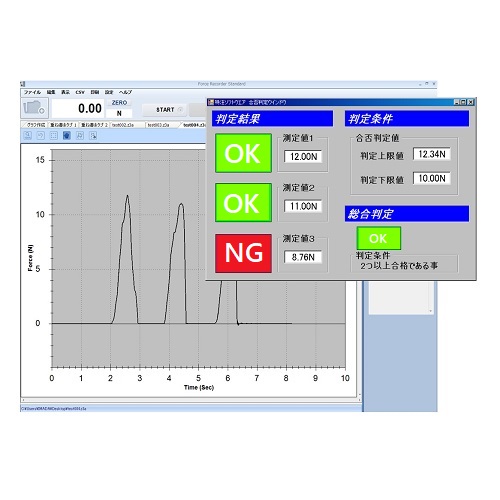

Multi-Peak Extraction Function

Multi-Peak Extraction Function

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

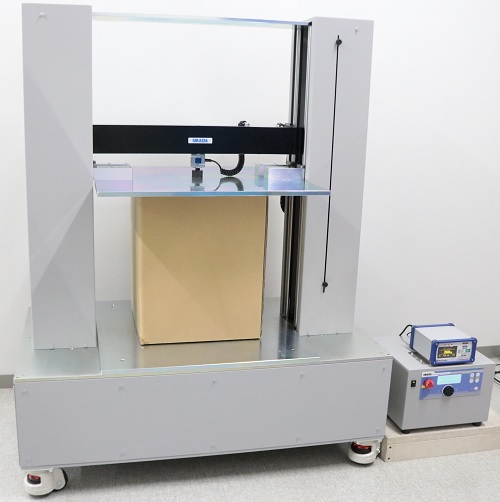

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

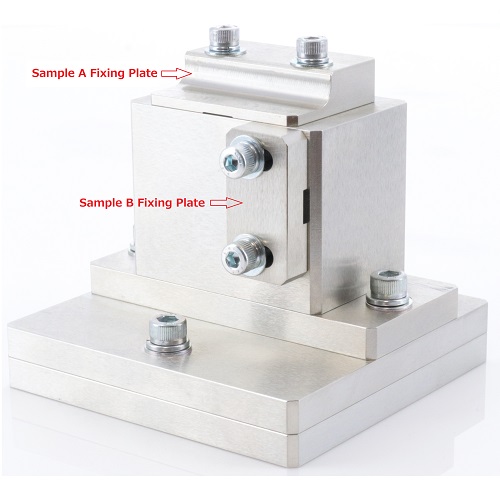

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

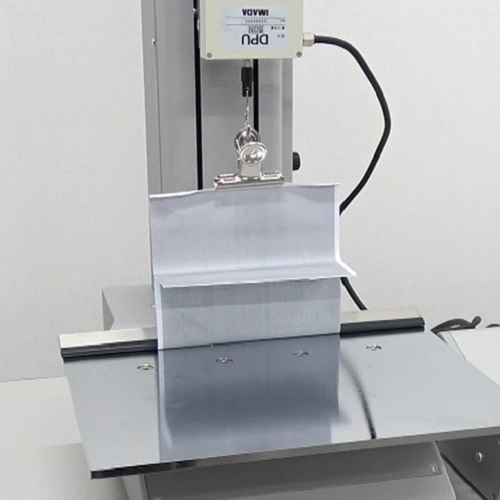

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

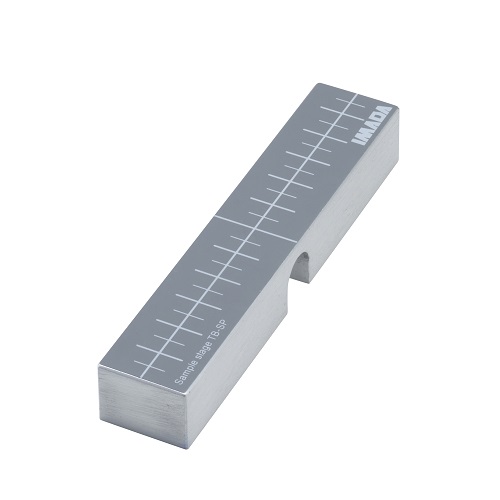

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

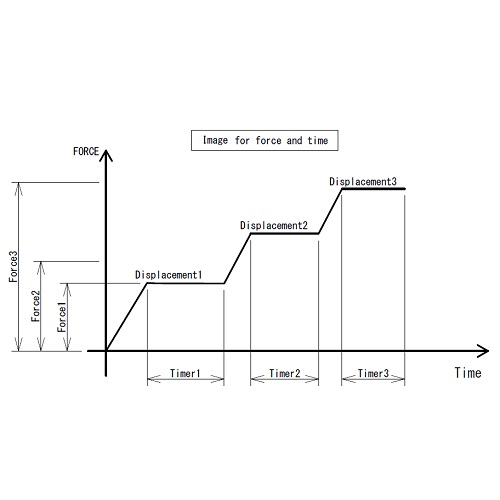

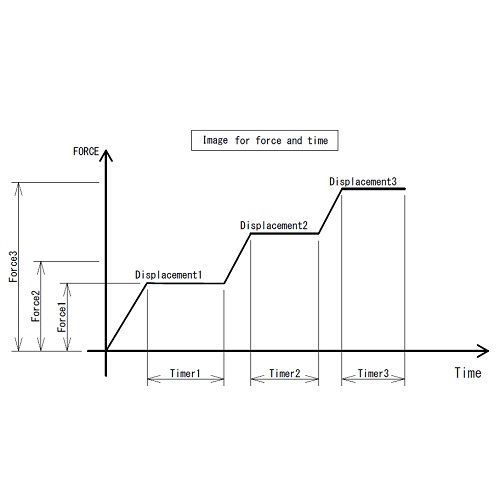

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)

.webp)