Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

Crucial points to select a force-gauge manufacturer

Crucial points to select a force-gauge manufacturer

- Force Measurement IMADA

- SERVICE & SUPPORT

- Crucial points to select a force-gauge manufacturer

The force gauge is a device used to measure the force applied by pushing or pulling, and it is used for strength testing in quality management. Since measuring force in daily life is not common, many people may be unsure about what criteria to use when considering the purchase of a force gauge or other load measuring instrument. In reality, selecting a force gauge or similar load measuring instrument often requires specialized knowledge, so it is common to consult with manufacturers for selection. This is because the objects that can be measured with a force gauge range from automotive parts to food and encompass a wide variety. If the selection of the product is incorrect, it may result in the inability to properly apply force to the object being measured or the inability to obtain the desired data. Therefore, choosing the right manufacturer becomes important. Here, we have summarized the points to consider when selecting a force gauge manufacturer for your reference.

The points to consider when selecting a force gauge manufacturer

- Does the manufacturer have problem-solving capabilities?

- Is it possible to have a trial measurement or try out the product before making a purchase?

- How about post-purchase maintenance and support to ensure customer satisfaction?

1. Does the manufacturer have problem-solving capabilities?

Objects measured by force gauges vary widely, and the measurement methods and fixtures (attachments) used also differ. If the selection of measurement methods and attachments, as well as other product choices, is incorrect, it can lead to measurement failures such as the inability to secure the measured object properly, obtaining unexpected data, or failing to meet desired specifications. To avoid this, it is recommended to rely on manufacturers for selection. Firstly, the most important factor is whether the manufacturer can solve the load measurement challenges that customers are facing. Therefore, it is crucial to choose a manufacturer that can provide proposals and solutions for the specific challenges.

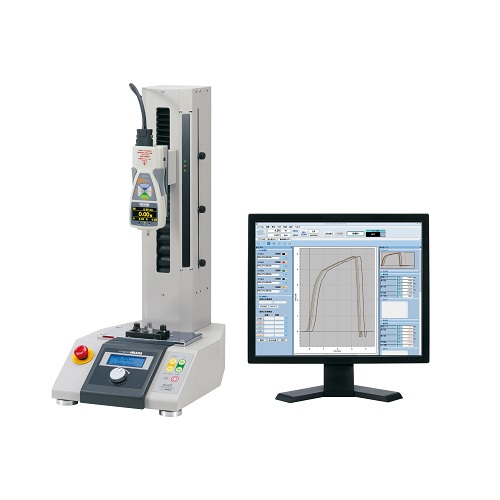

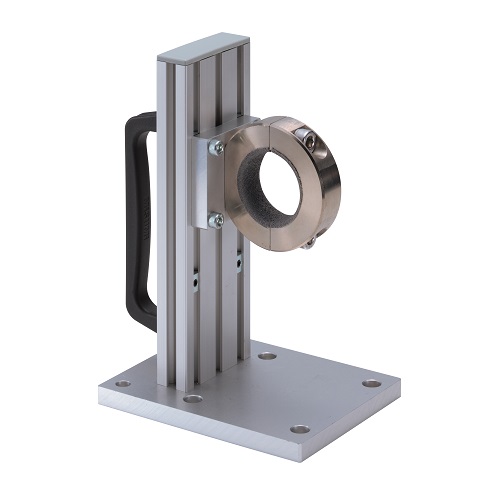

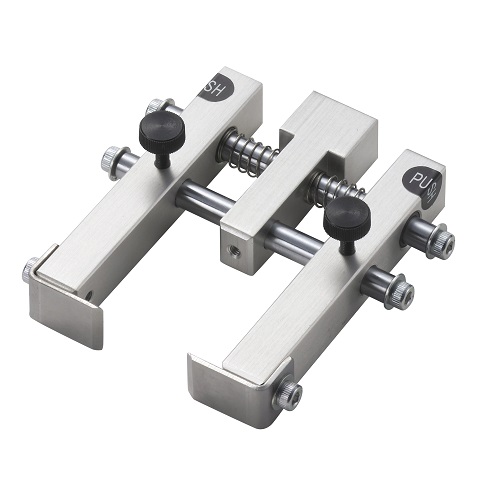

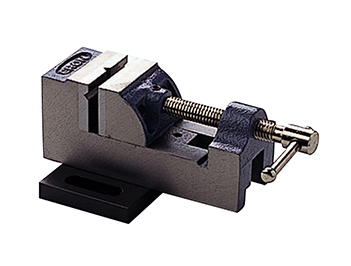

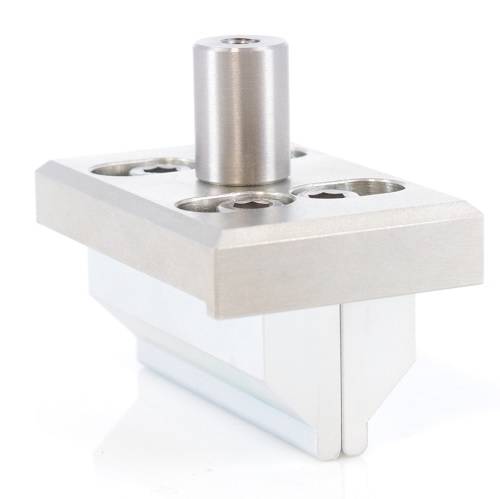

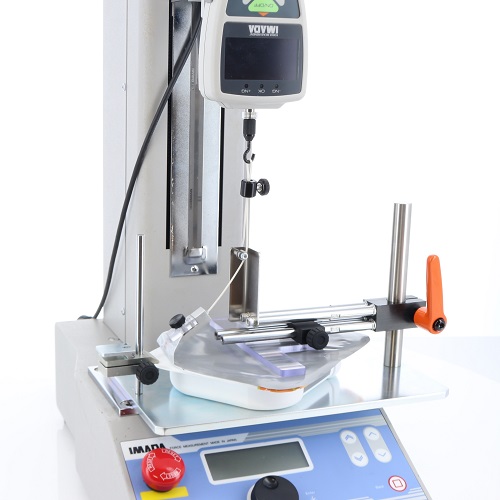

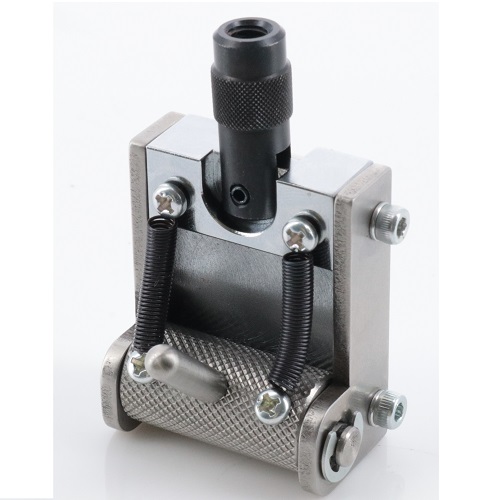

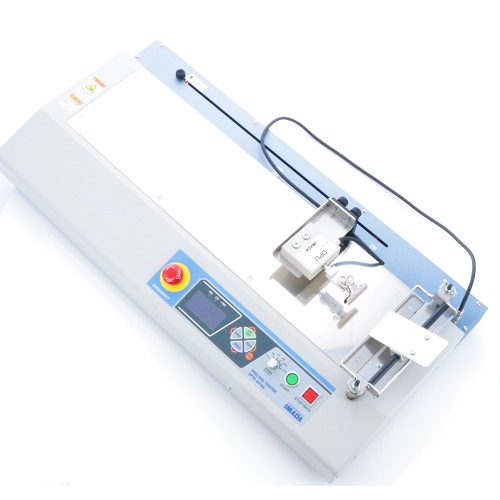

This is just an example of force gauges & attachments among many:

[IMADA's approach]

Compatible with a wide range of measurements with approximately 100 types of attachments | To meet a wide range of measurement needs, the number of attachments continues to increase each year. As of 2023, we offer a standard lineup of approximately 100 types of attachments. In another page of this website, you will find numerous video examples of measurement cases for your reference. |

Approximately 3,000 custom-made orders over the past 20 years | If our standard products do not meet your requirements, we offer custom-made solutions. Since around 2003, we have established a dedicated department for custom manufacturing and have completed approximately 3,000 custom-made orders over the past 20 years. We pride ourselves on being flexible and accommodating to our customers' specific needs. While maximizing the utilization of standard products, we strive to provide cost-effective proposals. |

Accumulated expertise in various standards such as JIS, ISO, etc | We have handled a wide variety of standards, totaling over 100 different types, throughout our history. Our experience covers a diverse range of industry-specific standards, international standards, and regional regulations. This breadth of expertise allows us to effectively address the specific requirements and compliance needs of our customers. |

Collaborative researches with universities | We conduct collaborative researches with universities to pursue load measurement from an academic perspective and enhance my expertise. |

2. Is it possible to have a trial measurement or try out the product before making a purchase?

To prevent any purchase mistakes, it is recommended to conduct trial measurements and verification to ensure that the actual objects can be measured accurately before making a purchase. For example, even if it is confirmed that the object can be securely fixed and subjected to force, there may be instances where the data cannot be output as expected due to the performance of the force gauge or software. It is advisable to communicate your specific requirements, including data output, to the manufacturer in advance, receive their product selection suggestions, and confirm during trial measurements or product trials if your requirements are being met. This will help prevent any potential purchase mistakes.

We provide the following services to ensure that we meet your requirements and offer reliable measurements and data output methods, even in cases where your requirements may be unclear. Our goal is to ensure your satisfaction and peace of mind before making a purchase.

[IMADA's approach]

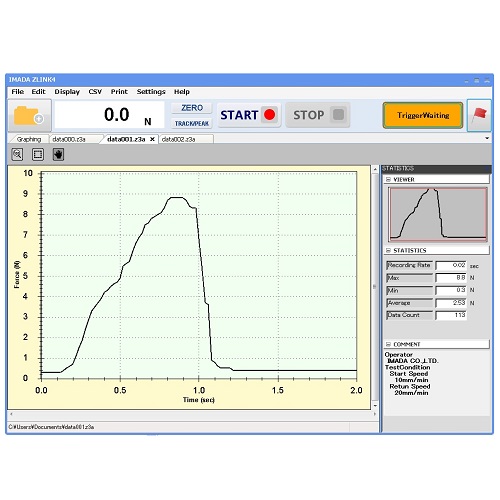

| Sample testint service | We offer a service where our engineers will listen to your measurement requirements, and upon receiving samples of the objects to be measured, we will provide a report summarizing the optimal measurement method and the necessary products. We guarantee a reliable selection process. For more details> |

Trial measurements in our showroom | We offer a service where you can conduct trial measurements and product demonstrations in our showroom, which we refer to as the laboratory. We have a complete range of models available, and when you visit our facility, our engineers will be present to assist you. You can experience the products firsthand, assess their usability and specifications. If visiting our facility is difficult, we can still assist you by conducting measurements on your samples remotely through video calls. We will show you the measurement process and provide real-time guidance and explanations. Please let us know if you would like to proceed with this remote measurement service, and we will arrange the details accordingly. For more details> |

3. How about post-purchase maintenance and support to ensure customer satisfaction?

When conducting quality-related measurements with a force gauge, it is important to treat it as a resource for monitoring and measurement purposes, requiring appropriate management. Generally, a management system is established using regular calibration and calibration certificates as evidence of calibration results. Additionally, as it plays a role in inspection or other stages of production, maintenance is also a crucial consideration in order to ensure its reliability.

| Recquired maintenance | Subject | Frequency | Cost |

| Calibration | All force gauges | once a year | Request a quote |

| Battery replacement | All digital force gauges | once every 2 to 3 years | Request a quote |

There are customers who are still using force gauges purchased from Imada 30 years ago. When it comes to any manufacturer, once you make a purchase, the support provided after the purchase becomes a crucial point as it signifies a long-term partnership.

[IMADA's approach]

Calibration tailored to your needs | In addition to manufacturer calibration, we also offer calibration services as an ISO/IEC 17025 accredited calibration facility, certified by a third-party organization. We provide calibration certificates and documentation for traceability as well. For more details> |

Authorized distributors located in various parts of the world | Imada has partnered with distributor companies worldwide through dealership agreements. If you encounter any difficulties, you can consult with the local authorized distributor for assistance. |

Simplification of maintenance | In terms of maintenance, we also offer the sale of consumable parts such as batteries for digital force gauges, or a part of attachments. This allows customers to perform partial maintenance themselves. For reference, here is a video demonstrating the battery replacement process> |

| User-guide videos | We have created concise and user-friendly instructional videos to explain the functionality and settings of our products. You can find a list of these user guide videos here> |

Customer support team ready to assist you | If you have any questions regarding usage or maintenance, please feel free to reach out to us for assistance. You can contact us via phone, our website, or email. We also work closely with our local authorized distributors to ensure comprehensive support. |

When contacting the manufacturer regarding your force gauge inquiries, here are some helpful tips:

- Provide detailed information: If you have a clear understanding of the measurement object, budget, desired features, or challenges you are facing, please communicate them in detail. Sharing information about the shape, material, and size of the measurement object through documents or photos can greatly facilitate the information exchange process.

- Don't hesitate to inquire: Even if your desired requirements or challenges are not fully defined, feel free to reach out. Sometimes, you may have a general sense of needing certain measurements without specific details. By sharing your concerns and uncertainties, the manufacturer can help unravel the situation and propose suitable solutions. This is where the manufacturer's expertise shines.

By following these suggestions, you can ensure effective communication with the manufacturer and receive tailored recommendations and support for your force gauge needs.

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

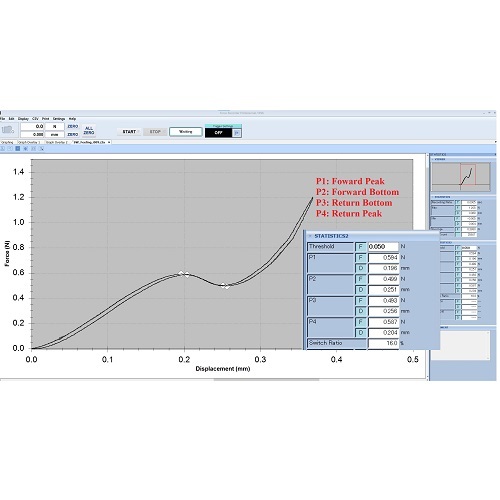

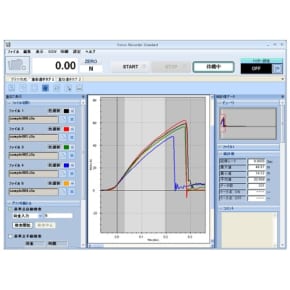

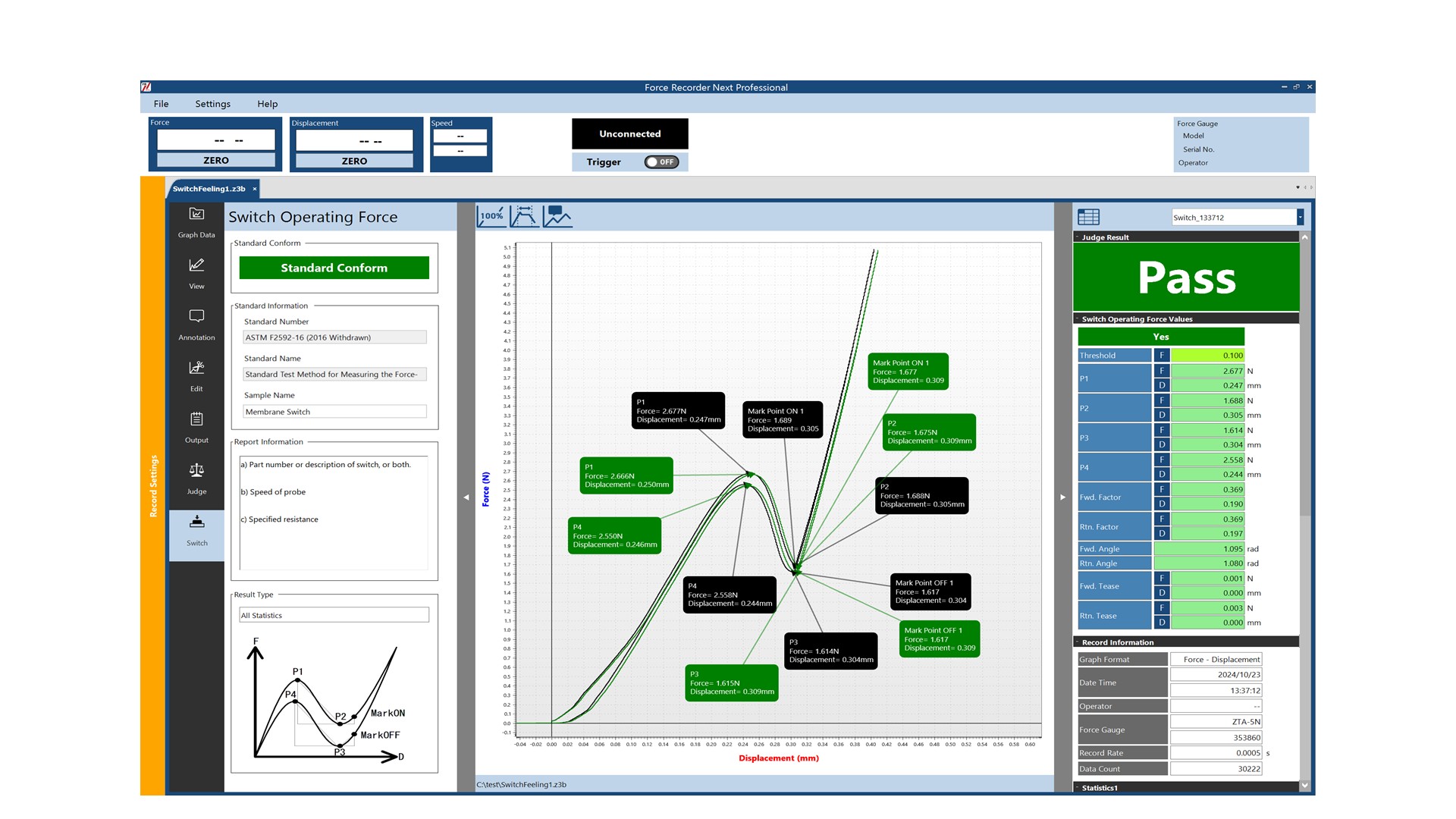

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

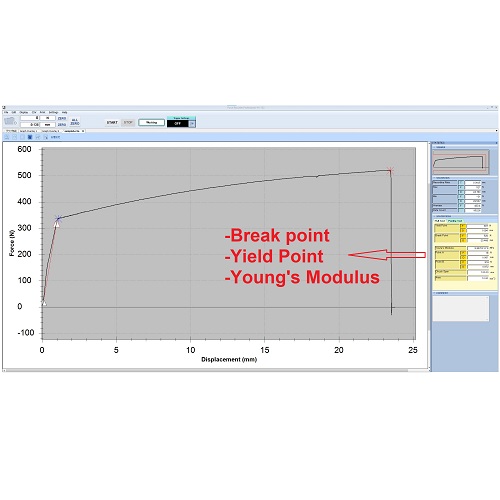

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

Multi-Peak Extraction Function

Multi-Peak Extraction Function

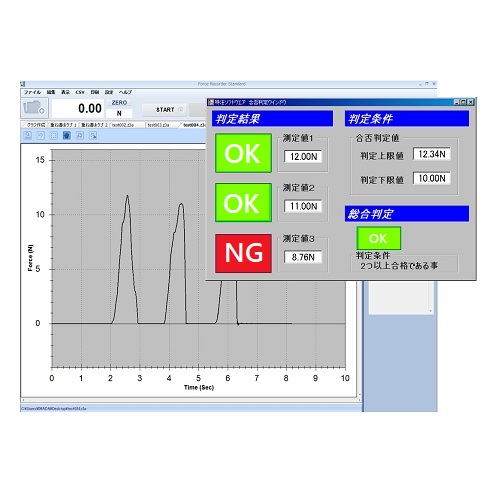

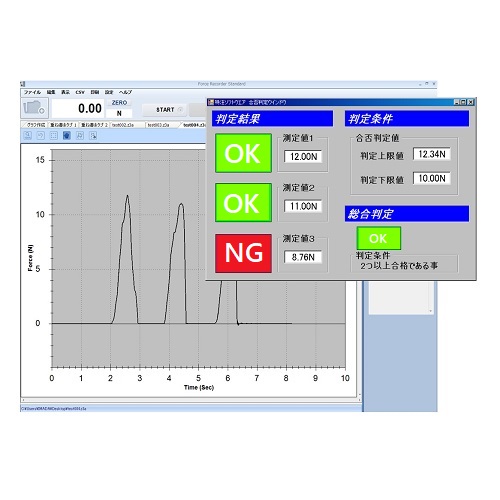

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

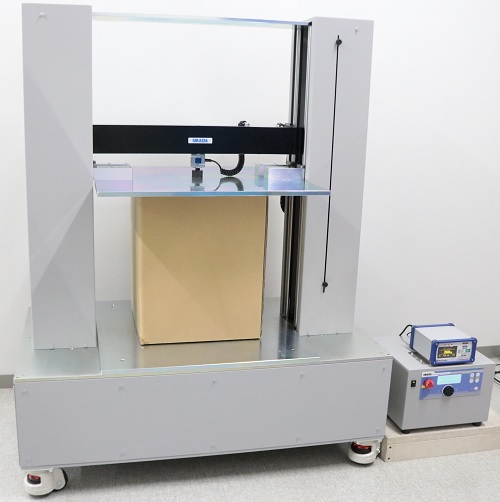

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

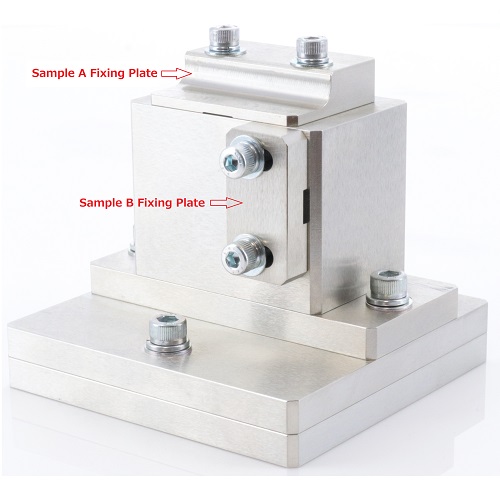

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

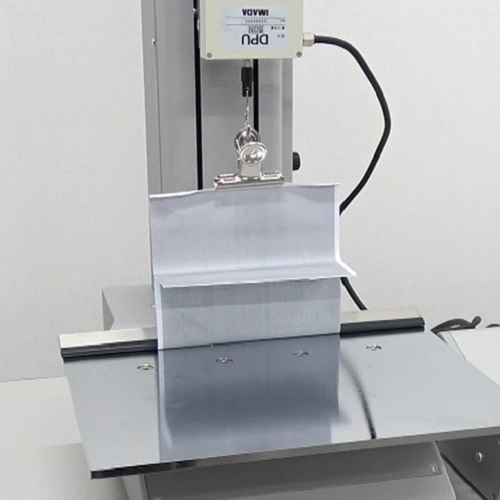

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

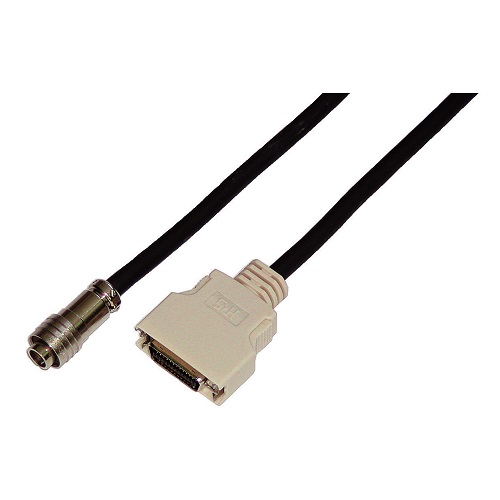

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

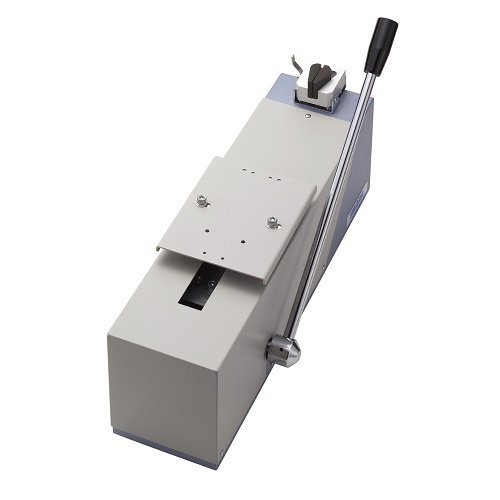

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

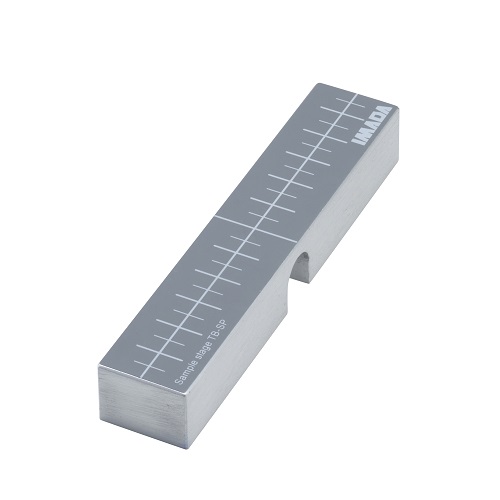

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

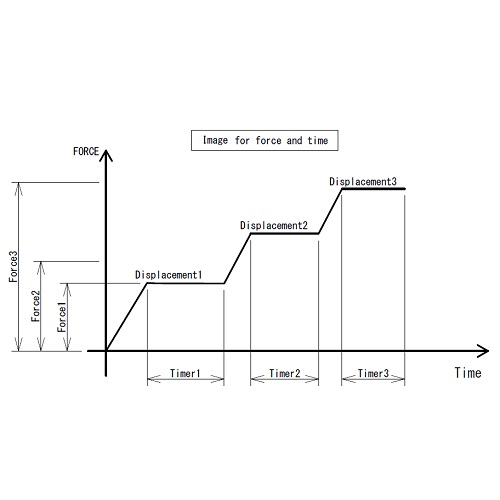

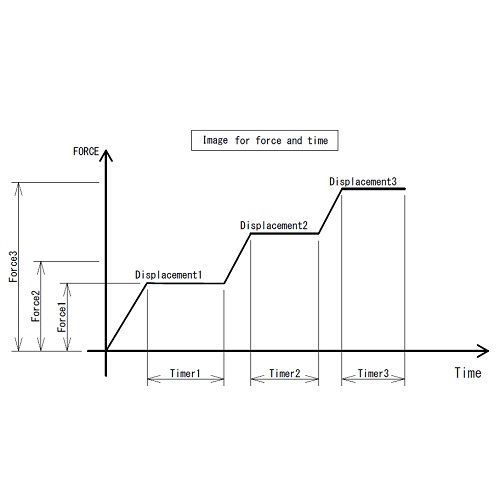

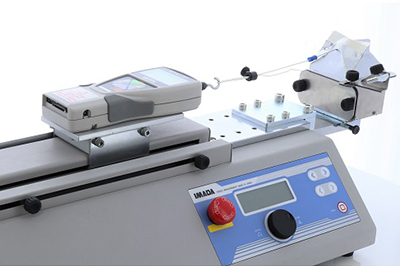

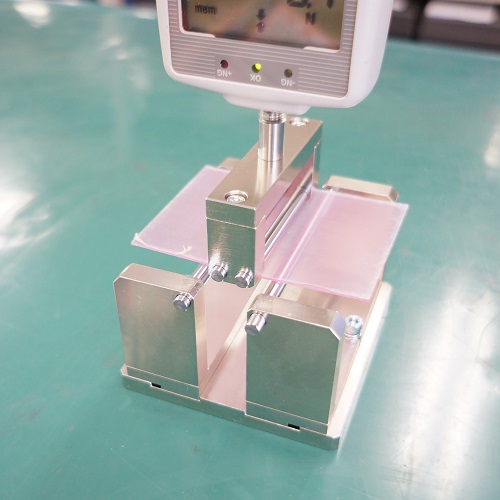

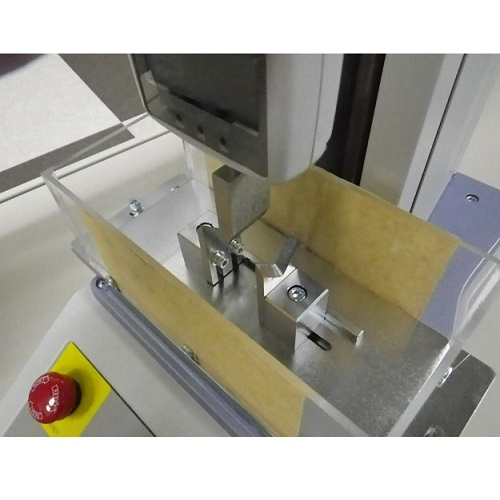

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

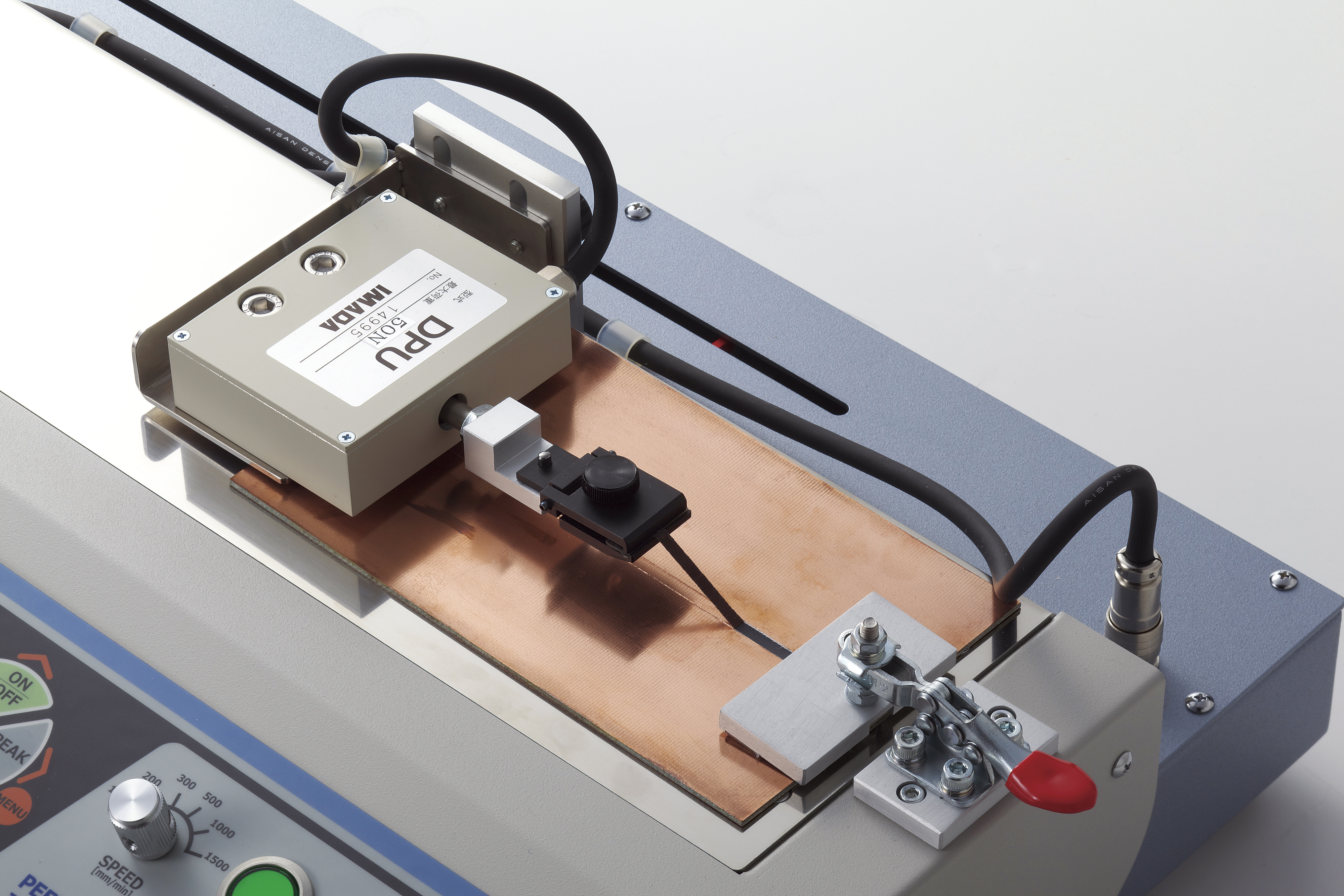

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)