Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

SOLUTIONS

Basic Principle of Force Measurement

Force

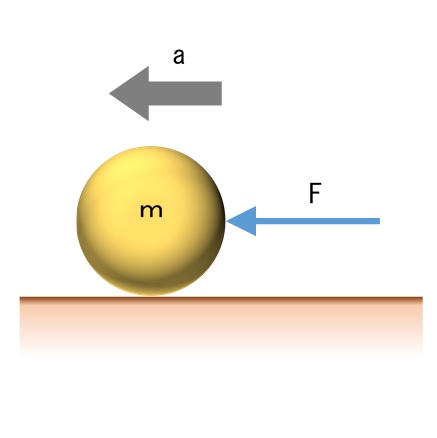

In physics, force (power) is an action that "deforms an object" or "changes the velocity of an object", and is a physical quantity that expresses the magnitude of that action, defined as mass (m) x acceleration (a) = force (F). As shown in the video pages of each test on this website, there are several types of force, such as tension, compression, shear, bending, and friction, and the magnitude of these forces is expressed in units of "N (Newton)".In our daily lives, forces are generated everywhere. Force is generated not only in lifting and pulling things, but also in the act of chewing food and turning doorknobs, as you may be very familiar with. There is also a well-known force that is at work not only when we are moving, but also when we are at rest. That is gravity. Gravity, caused by the earth's gravitational pull and rotation, allows us to move on the earth in contact with the ground.The acceleration of gravity on the earth varies from place to place, but the internationally agreed standard value is g = 9.80665 m/s2. For example, the magnitude of the force on an object of 1 kg mass at rest is calculated to be 1 (kg) x 9.8 (m/s2) = 9.8 (N), which is about 9.8 N.

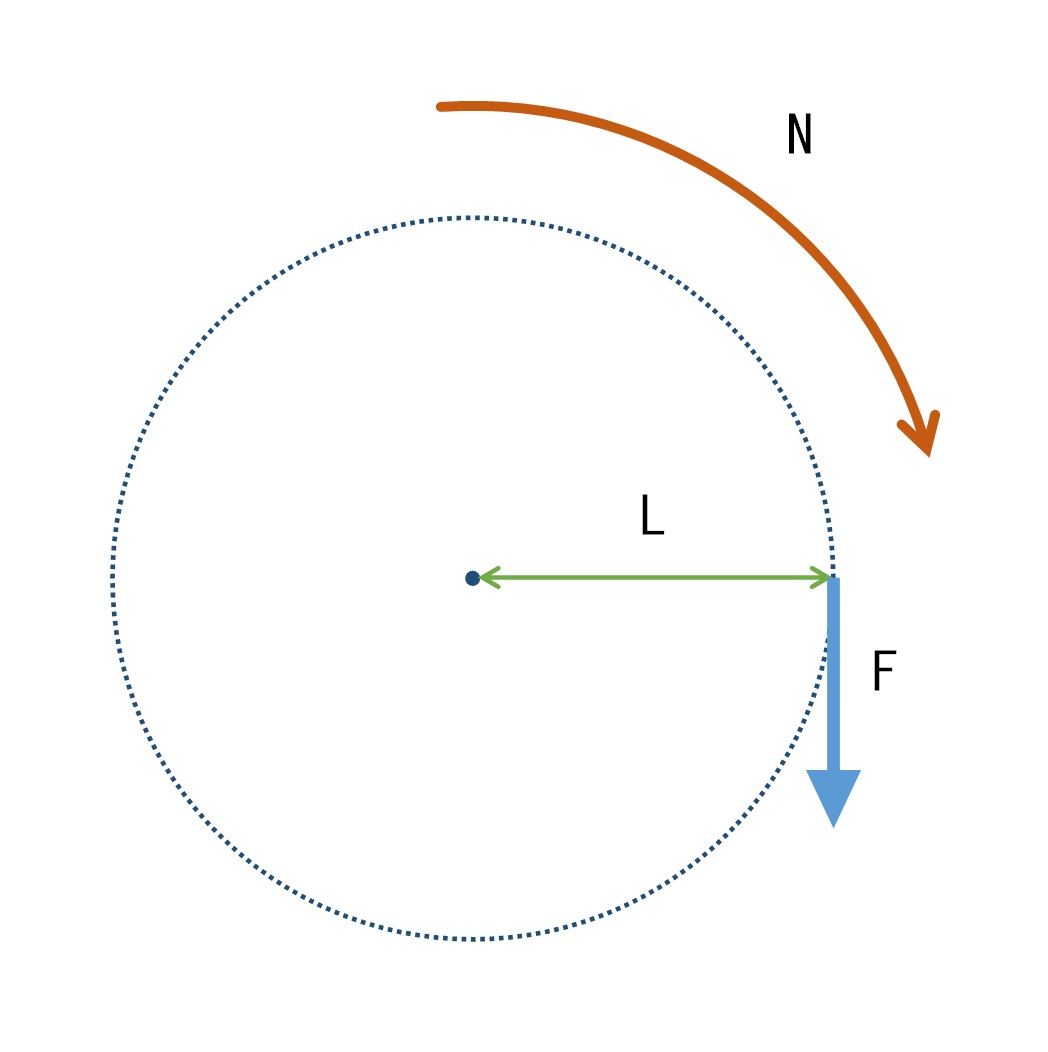

Torque

Torque is "the magnitude of force, torsional moment (turning or twisting force) that acts on an object when it rotates". Torque is the result of force multiplied by distance, and is defined as force (F) x distance (L) = torque (N), and the unit of torque is expressed in "N-m (Newton meter)".The greater the distance to the point of force action, the greater the torque will be for the same amount of force (F). This is the same as the "The Principle of Leverage". For example, when turning a door handle to open a door, the longer the handle, the easier it is to open the door. If the same torque is required, a longer distance (L) from the point of action will result in a smaller force (F).We perform actions that generate torque on a daily basis, such as opening the lid of a plastic bottle or turning the dial of a car air conditioner. Therefore, on site of product development and quality control of companies, measurement of torque values is commonly used as one indicator to check the usability and safety of products.Click here for torque gauges >

Measurement Act

According to the Measurement Act that came into effect on November 1, 1993, Force, Moment of Force, Pressure, and Stress cannot be used for transactions or certifications other than those based on the SI unit system (International System of Units) in Table 1 as legal measurement units.Under the current Measurement Law, the use of newton (N)" as a unit of force is mandatory in Japan. Measuring instruments with a scale other than the legal measurement units for expressing the conditions shown in Table 1 must not be sold or displayed for sale in Japan for the purpose of use in Japan.This explains why IMADA sells products with legal unit scales to Japan.Table 1 Excerpt from "Measurement Units pertaining to SI Units" (Ministry of Economy, Trade and Industry)Quantity of state ofphysical phenomenaSymbolMeasurement UnitForceNNewtonMoment of forceN・mNewton meterPressurePa, N/m2, barPascal, Newton per square meter, and BarStressPa, N/m2Pascal, Newton per square meterViscosityPa・s, N・s/m2Pascal second, Newton second per square meter*The conversion with conventional units of force is 1 kgf = 9.80665 N.

How to Measure Force?

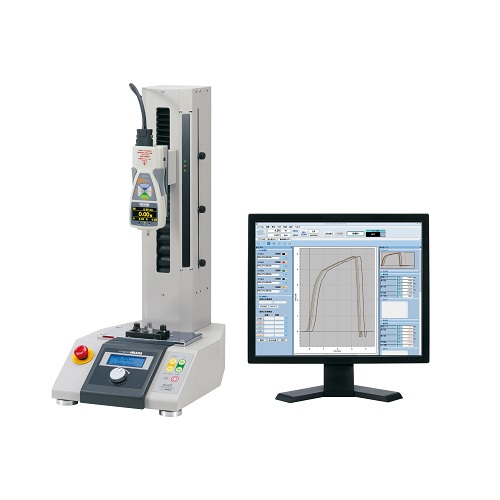

Force measurement is to express the force (force = load) generated by contact using a measuring equipment. Since there are several types of forces depending on the direction of the applied force and other factors, measurement is performed in a manner corresponding to each type.As described in the "Force (Power)" section, force is generated in various situations in our daily lives, so force values are measured as one of the indicators to check the usability, safety, and taste of products and items that we come in contact with in our daily lives. For example, if the force value of the packaging material used to break a bag of pastries is too high, it requires a lot of force to break it, making it inconvenient to eat, while if it is too low, it can be easily broken, increasing the risk of damage during transportation. Also, the bread itself can be measured by measuring the force value when it is pressed, and the texture, such as "fluffy" or "chunky", can be seen in the numerical values.A force gauge is a typical measuring device for such force measurement. A force gauge is a tool to quantify and express the generated force in an appropriate unit. By using force gauges together with attachments or stands that are appropriate for the force to be measured, various forces such as mechanical strength due to breakage or deformation of materials, sensation of hardness or softness, operating force and functionality of switches and brakes, etc. can be measured as data. While using such measuring equipment, force measurement is widely used mainly in quality control, research and development, training, and other situations.Click here for force gauges >>

Description of Calibration

Calibration refers to the process of determining the relationship between the value indicated by a measuring equipment and its true value, and correcting the scale.Just as a clock is checked for correctness using a time signal (standard time), measuring instruments must be periodically checked (calibrated) using standards and standard samples specified by national standards. Measuring equipment will always differ from ideal values depending on the environment in which they are used, how they are used, and how often they are measured. IMADA recommends periodic calibration of measuring instruments to maintain the accuracy of your measuring equipment and to ensure reliable measurements.

SOLUTIONS BY FORCE

Compression Test

We have a variety of videos demonstrating compression testing, including methods, equipment, fixtures, and data acquisition procedures. Some examples adhere to interntional standards for compression testing. What is Compression Testing? It is a method of measuring the force, where force is applied in the compression direction to the test specimen using instruments like force gauge and sensors. This test is primarily used to confirm the mechanical strength (compressive strength) and mechanical functionality (such as operational comfort) of the specimen, with the unit of measurement in N(newton). Compressive strength indicates how much compressive load the test specimen can withstand. For instance, if the strength of a candy box is too weak, it may lead to candies breaking during transportation and foreign objects entering through the gaps of the crushed box. Compression testing ensures the safety and security of manufactured goods. However, the applications of compression testing go beyond strength confirmation. It is also used to evaluate operational forces, such as pressing buttons on a keyboard, and assess comfort. Comfort, in this context, refers to the ability to move with just the right amount of force. If not optimal, it could negatively impact brand image. Therefore, from a branding perspective, functional evaluation through load measurement, including compression testing, is crucial. For more details on compression testing, please refer to the provided PDF document below. What is a Compression test?.pdf

Tension Test

Tensile testing is one of the methods for force measurement, where force gauge or sensor is used to apply a tensile force to a test specimen. It is primarily used to determine the mechanical strength (tensile strength) and operational force of the specimen by obtaining numerical values. The unit of measurement is in N(newton). Tensile strength refers to how much tensile force a test specimen can withstand. For example, a typical component used in digital devices is a wire harness. If the crimped terminal of the harness has insufficient strength and easily detaches, it can lead to not only malfunctions but also causes discharges, overheating, and potentially serious accidents. Tensile testing is a means to understand the strength of objects and ensure the safety and reliability of manufactured products. However, the application of tensile testing goes beyond just verifying strength. For instance, it can also be used to evaluate the operating force of caps on packaging containers (those that need to be pulled to open). This evaluation, in turn, helps assess comfortability, which can be defined as the ability to move (or open) with just the right amount of force. If comfortability is compromised, it can negatively impact a brand's image. Therefore, from a branding perspective, evaluations using force measurement, such as tensile testing, are crucial. At IMADA, we mainly handle tensile testing machines for measuring tensile forces up to 5000N. Below, we have provided a video showcasing an example of tensile testing for your reference. What is a tension test?.pdf

Compression-Tension Test

Compression-Tension test, as the name implies, is the test in which forces in the compressive and tension directions are applied during the same test to evaluate their interaction characteristics. Tack test and Extraction/Insertion test are described in detail. : Tack test is one of the evaluation methods for adhesion and stickiness. The probe is pressed against the sample at a pre-set force value, and after a certain period of time, it is pulled away from the sample to measure the force at which the probe is removed from the sample. : Extraction/Insertion test measures the resistance force (exertion/insertion force) when the probe is inserted or extracted. The force you may feel when you insert (or pull out) USB memory or SD card into an electronic device such as PC is an obvious example. The change of resistance is measured by repeatedly inserting and removing the device.

Texture Test

Texture Test analyzes texture, one element of food taste, from various perspectives, and evaluates its characteristics numerically. In addition to measurements based on texture profiles and complying standards, the following measurements can be performed. : In the Hardness/Elasticity aspect, the texture of meat and confectionery is evaluated in terms of repulsive force, and the breakability of samples is evaluated in the three-point bending test. : In the Cutting Resistance aspect, you can view a video showing the force value of cutting noodles and the firmness of boiled noodles, assuming the force required to bite through the food with teeth. : In the Stickiness and Smoothness aspect, the stickiness is measured by the resistance force when the probe is pushed into ketchup or other food and subsequently pulled up.

Torque Test

Torque Test evaluates changes in characteristics by applying a rotating force (torque) in the direction of turning or twisting a sample. Torque testers or handheld torque measuring instruments are used according to the sample. In addition to the torque value, the relationship between the torque value and rotation angle can be analyzed graphically. The following videos show the measurement of turning force, which is necessary to loosen screws coated with anti-looseness material, operating force, which is used to evaluate the moderation (click) of air conditioner knobs, and opening force, which is used to open PET bottle lids by turning them.

Peel Test

Peel Test is a test to characterize the force or process required to pull off a welded or bonded sample. 45° peel, 90° peel, 180° peel, and T-type peel are frequently used. Peeling force is the force required to peel adhesive tape, heat-sealed packaging film, jelly cup container lids, and so on. Peel force may be measured as a peak value, average value, or quantified together with peel distance (displacement value). In addition to the videos using a peel tester specialized for peel test, we also introduce peel test videos using a versatile vertical test stand and a force gauge with attachments suitable for various types of peel tests and samples. Here is an article comparing 90-degree peel tests and 180-degree peel tests Here is an article describing how to effectively perform peel tests

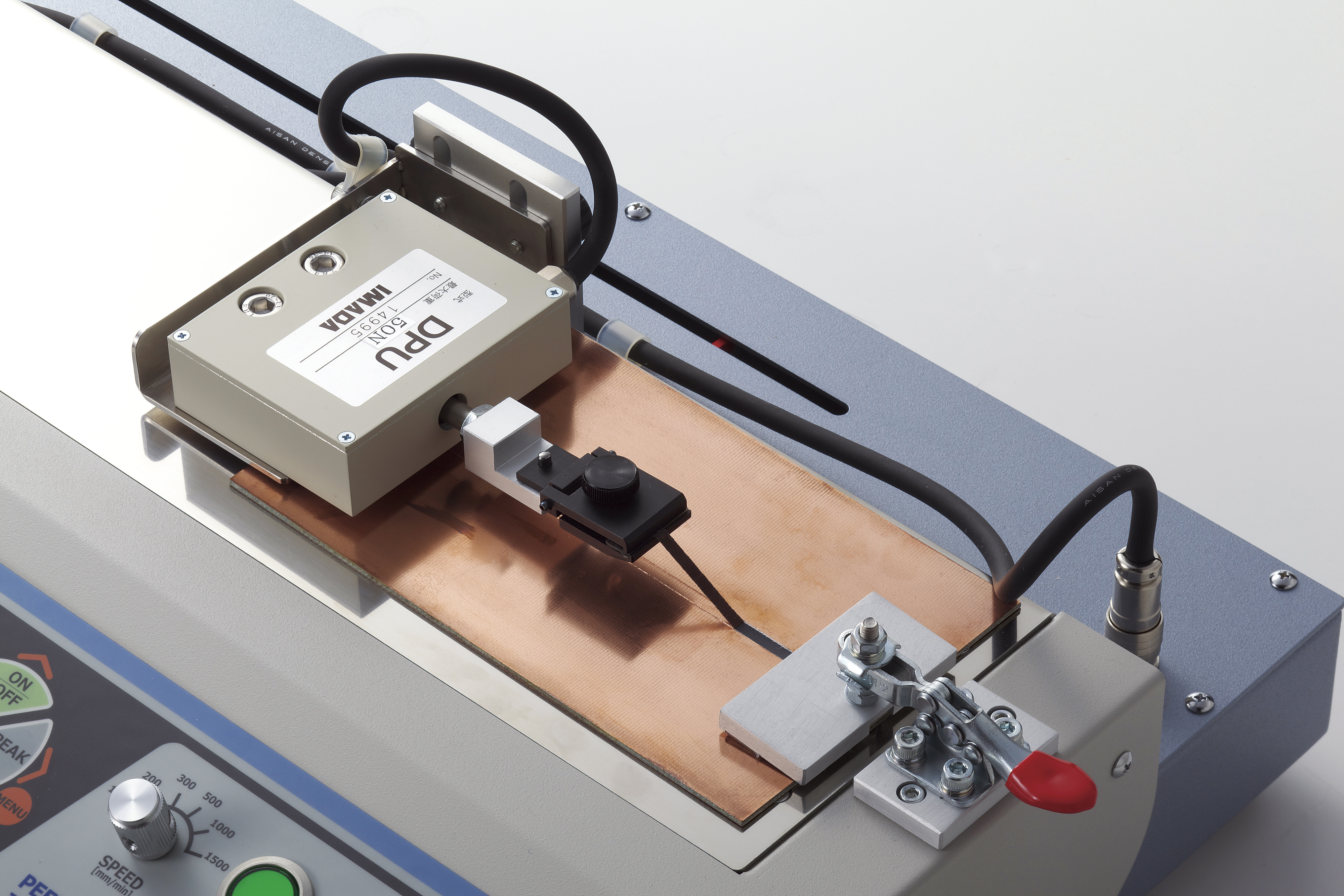

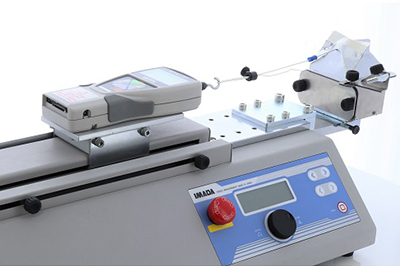

Friction Test

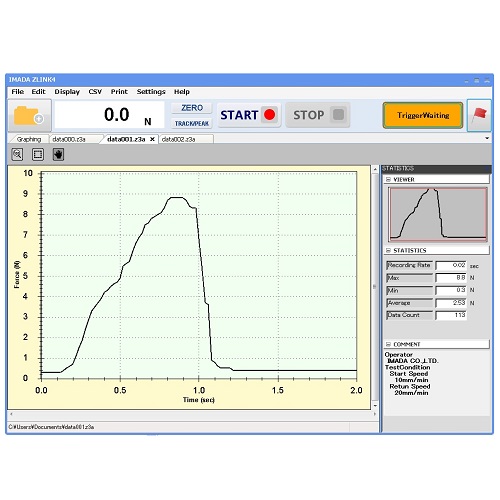

Friction Test is a test to measure the Coefficient of Friction based on resistance force (friction force) generated when a weight is placed on a sample and pulled or moved between two different types of samples. Usually both kinetic and static Coefficient of Friction are measured. The properties of paper, film, and other materials are often determined by industry standards, and examples of measurements that comply with these standards are also presented. In addition, using a pen and paper as a sample, it is possible to quantify and check the smoothness of the pen, which is one element of the writing comfort of a pen. In this measurement, dedicated software that automatically calculates the coefficients of kinetic and static friction can be used to increase the efficiency and convenience of the measurement.

SOLUTIONS BY INDUSTRY

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

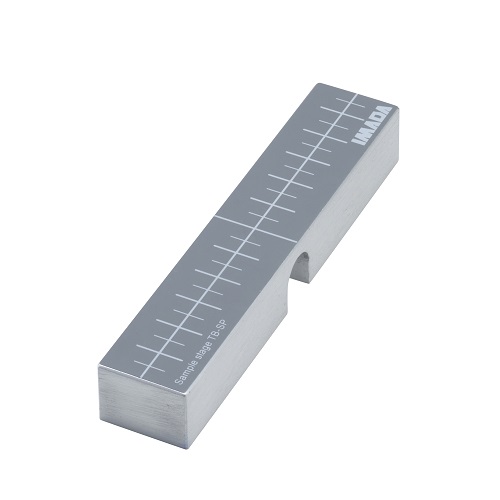

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

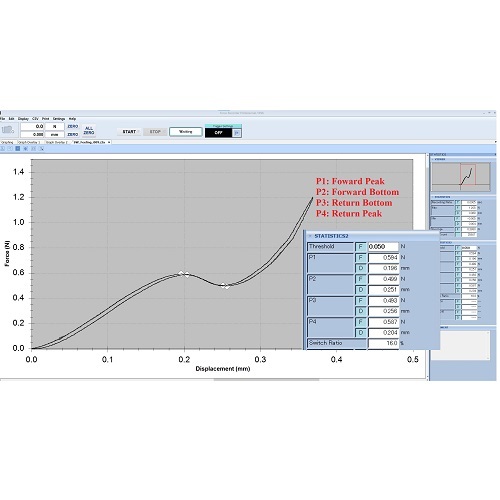

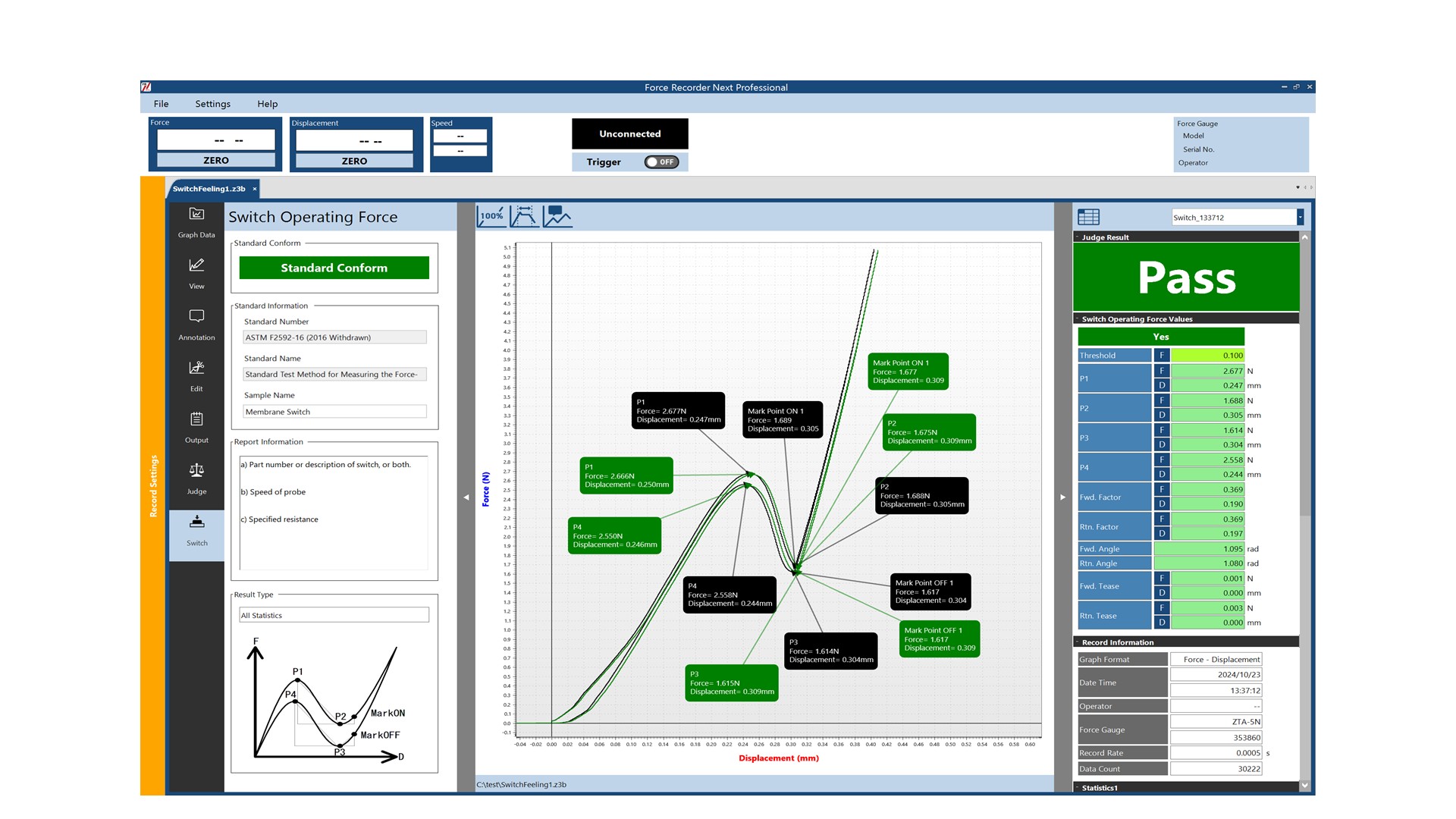

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

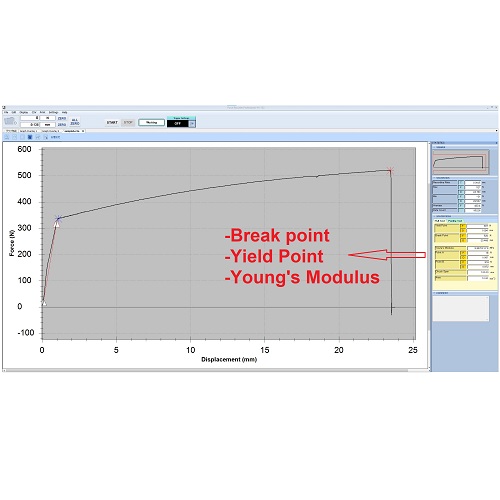

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

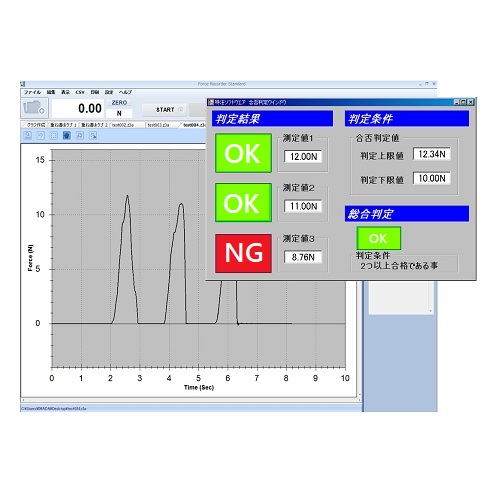

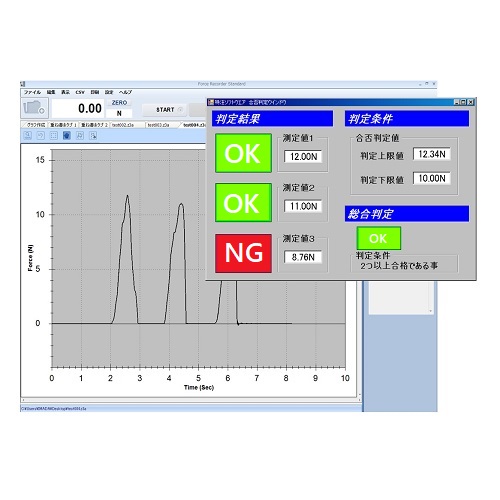

Multi-Peak Extraction Function

Multi-Peak Extraction Function

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

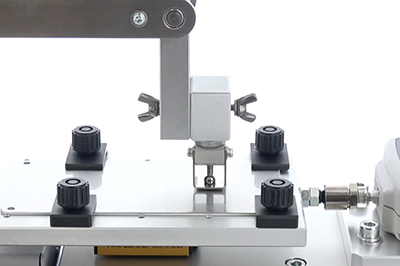

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

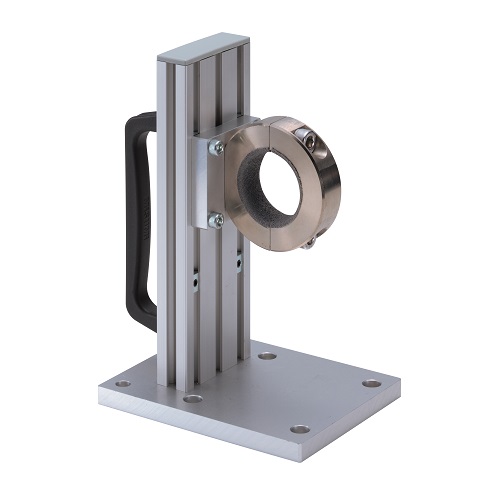

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

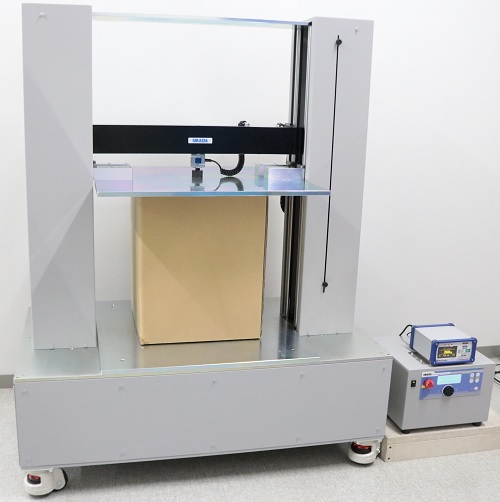

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

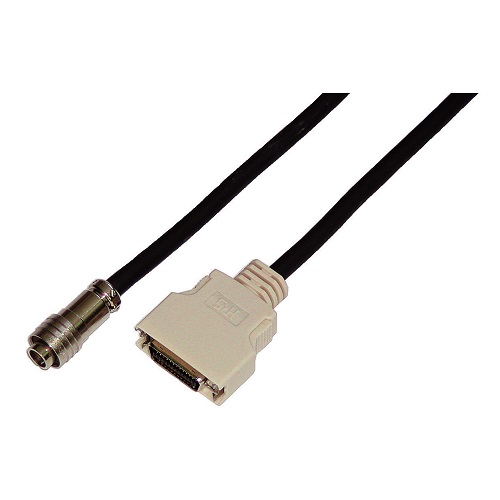

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

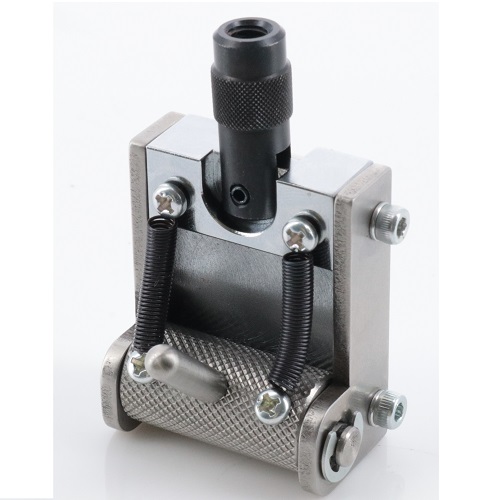

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

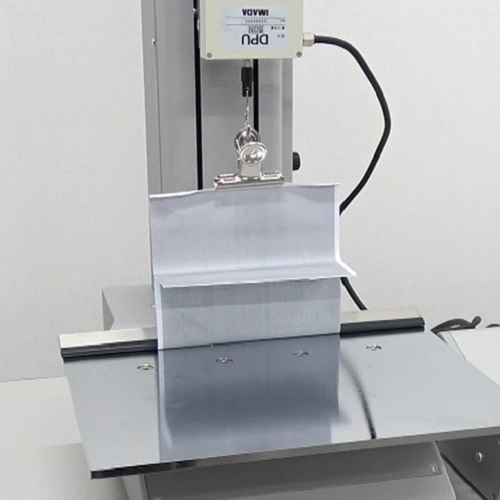

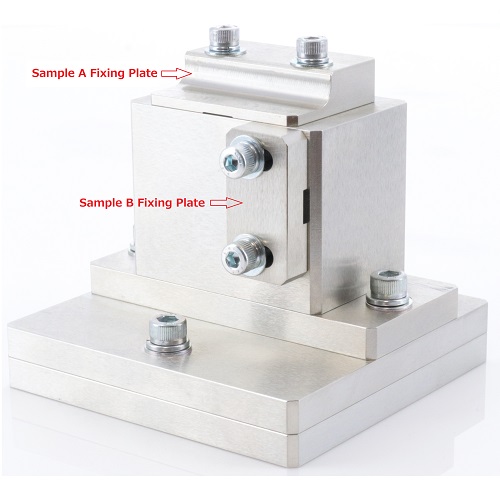

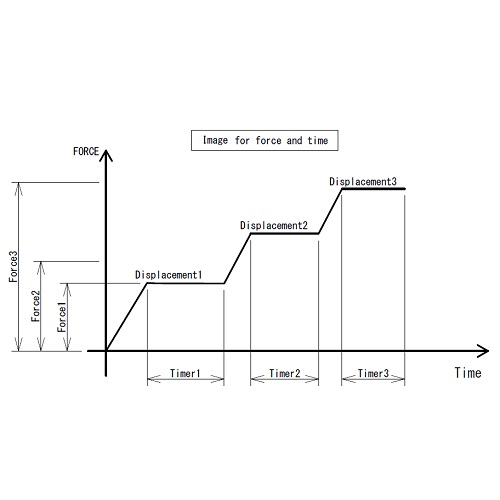

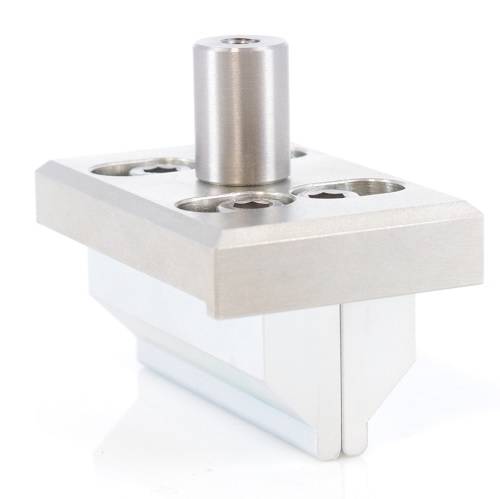

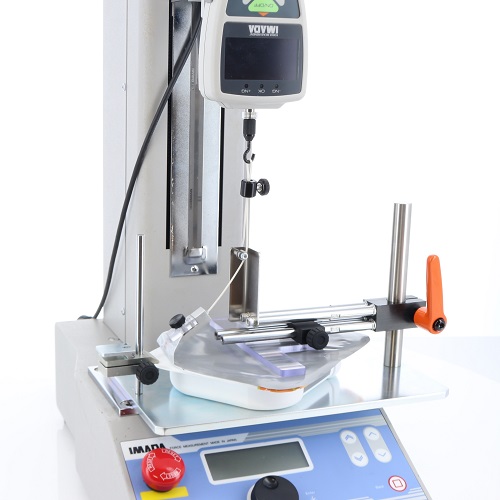

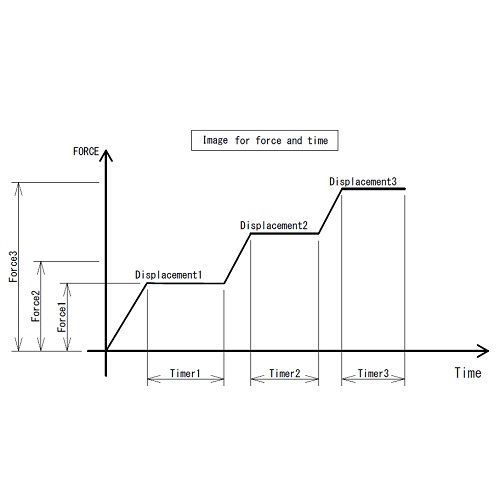

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

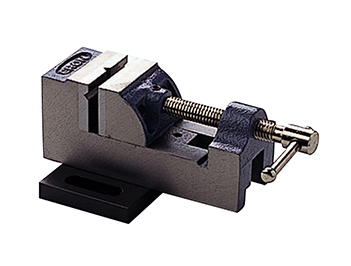

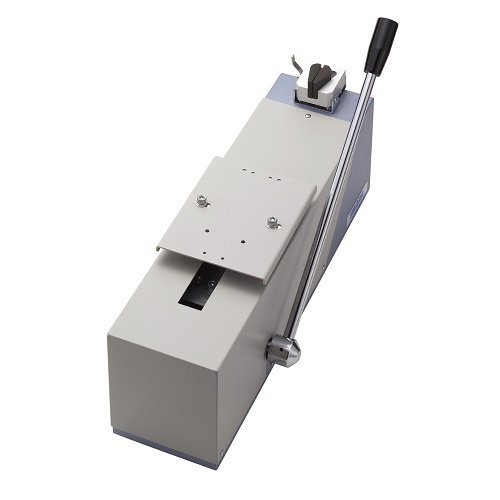

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

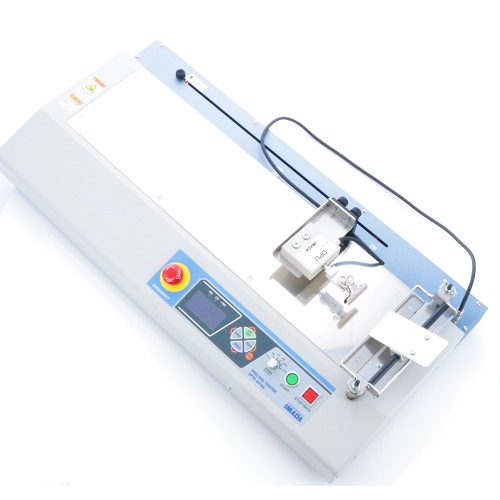

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

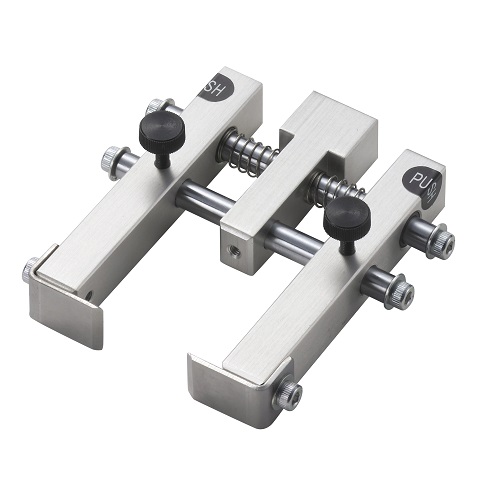

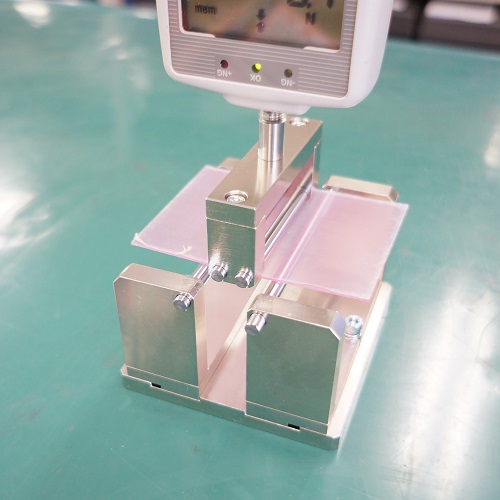

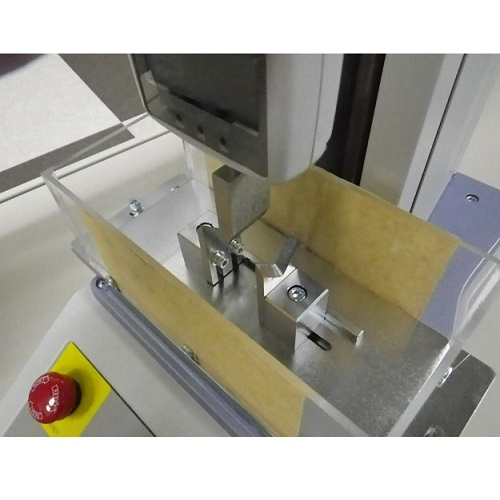

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)