Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

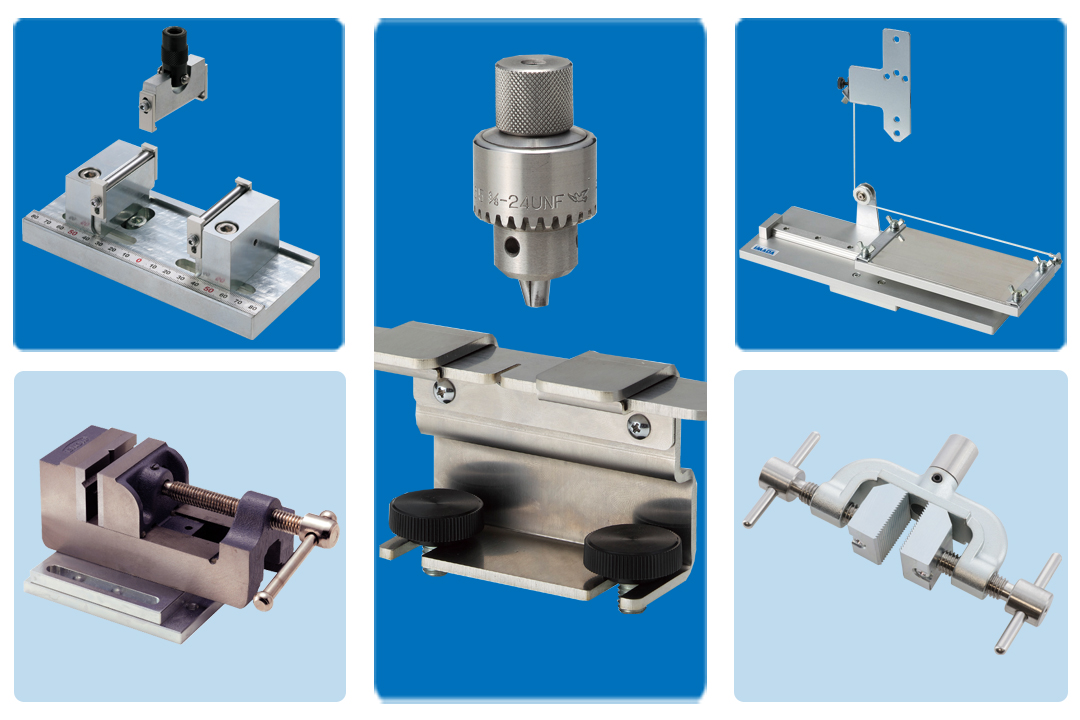

Attachment, Grip & Fixture Overview

Attachments, Grips & Fixtures

- Accessory Attachments

- Compression Attachments

- Tension Attachments

- Peel Test Fixture

- Friction Attachments

- Compression and Tension Attachments

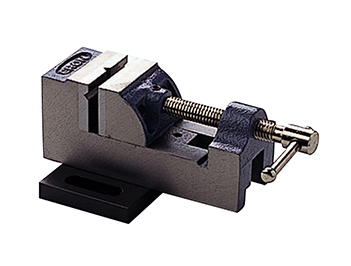

- Vise Grips and Tables

- Wire Crimp Pull Test Attachment

- Chip Components Tension/Shear Test Attachment

- Medical Attachments

- Pinching Force Test Attachment

- Torque Attachments

- Food Texture Tester Attachments

- Optional Handles, Conversion Adapters & Other Accessories

- Force Measurement IMADA

- PRODUCTS

- Attachment, Grip & Fixture Overview

Attachment Overview

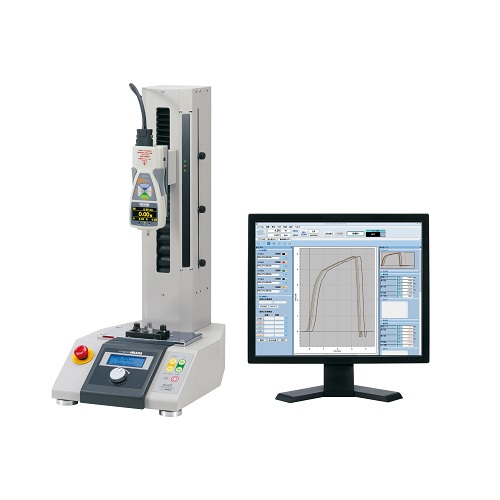

An attachment is a jig that is attached to a test stand or a test stand of a force gauge. Since it is the part of the attachment that actually contacts the sample to be measured, the attachment is a very important element in force measurement.

A force gauge can be used to measure compression force by attaching an attachment for compression test, and can measure tension force by replacing it with an attachment for tension test. In other words, a force gauge can read a force value, but the type of force to be measured is determined by the attachment, not the force gauge.

Even for a single compression test, there are various types of compression tests, such as a pressure test in which a force is applied to the entire test sample, or a puncture test in which a force is applied locally.

In order for a force gauge to properly measure your desired force, you need an attachment that is suitable for the purpose. It would not be an exaggeration that "the right attachment" is the most important factor in force measurement. Therefore, IMADA has continued to develop attachments to meet the measurement needs of our customers, and the number of types of attachments has been continuously increasing. We have reached the point where we offer over 230 types attachments as regular items.

Together with custom-made attachments, we manufacturer more than 300 types of attachments annually. The possibilities for force measurement is infinite, and the world of attachments is endlessly wide and deep, although it may seem small and inconsiderable.

Click here to see the complete lineup of attachments.

List of all attachments>

How Best to Select Attachment

There are four points to consider when selecting attachments.

1)Type of force. Force types are broadly divided into compression, tension, peel, and friction. Be distinctive about the type of force you want to measure.

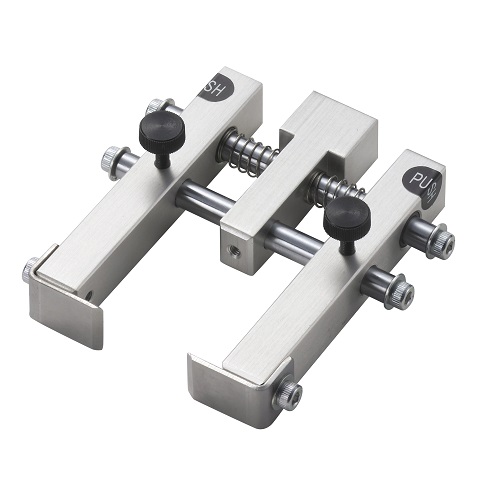

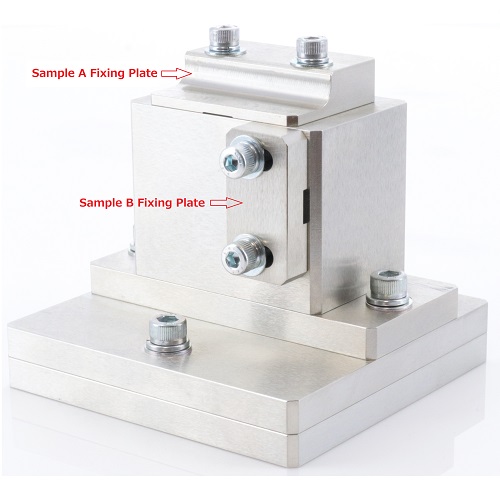

2)Shape and material of the sample. For example, even if the type of force is determined to be a tension, the attachment for gripping the sample will inevitably differ between a long, thin sample such as wire and a thin, flat sample such as film. Furthermore, even with the same wire shape, the optimal gripping method differs depending on whether the sample is elastic or not, how smooth (slippery) the surface is, and how easy it is to cut.

3)Priority in measurement. Even if the shape and material of the sample to be measured are the same, the selection will vary depending on what is important in the measurement, such as a one-touch fixation type when the top priority is measurement efficiency, or a screw fixation type when the degree of fixation needs to be adjusted manually depending on the sample.

4)Force value. Each attachment has a maximum allowable force value. We recommend an attachment with a slightly higher allowable force value than the force value expected to be required for the measurement. Also, since the weight of the attachment itself is recognized as a force by the force gauge, it is important that the weight of the attachment should be within 10% of the maximum allowable force value of the force gauge.

If you are still uncertain about the test type, or the force value, contact us for sample measurement services or online meeting for free.

Tips for more skillful use of Attachments

Attachments should not be underestimated. For example, the GCF series of chuck jigs allows you to easily replace the claw by yourself, and a variety of optional claws are available. If you have a spare claw, you can replace it immediately in case the claw wears out. If you have many samples to measure, having different claws available allows you to perform various measurements with a single attachment.

We offers accessories for attachments to improve the efficiency and quality of measurements. An adapter that makes it easy to attach and detach an attachment to a force gauge, a table for attachments that makes it easy to center a test sample, and other attachments that help improve measurement efficiency are among a few examples. There are also adapters with free joints to adhere to the measurement sample and prevent unbalanced load, as a way to help improve repeatability.

Some attachments conform to JIS, ISO, and other industrial standards. Measuring in a way that conforms not only to in-house standards but also to the standards of independent organizations is complex, but it may provide you a competitive edge. When you consider industry standards-compliant measurements and discover the standard products cannot be applicable, rest assured because we offer custom-made attachments as well.

Regarding custom-made, it is possible not only to conform to standards, but also to change the size and specifications of standard products. Since semi-custom orders based on standard products can be less expensive, we prioritize the process of quasi-custom orders first.

It isn’t too much exaggeration to say that mastering the use of attachments means mastering force measurement.

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

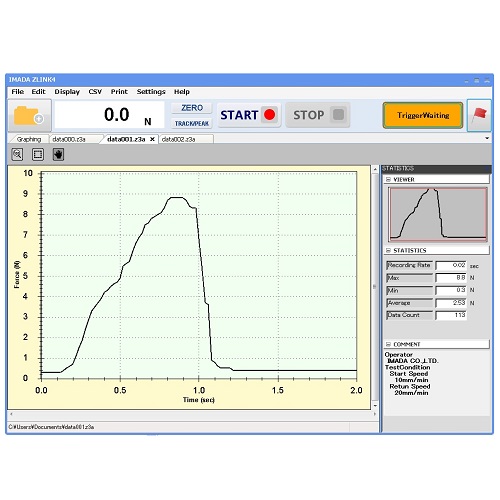

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

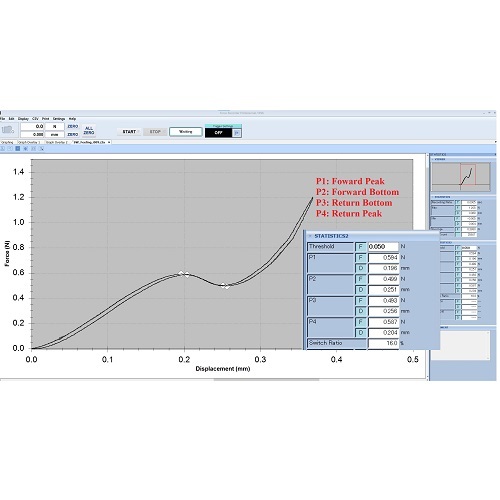

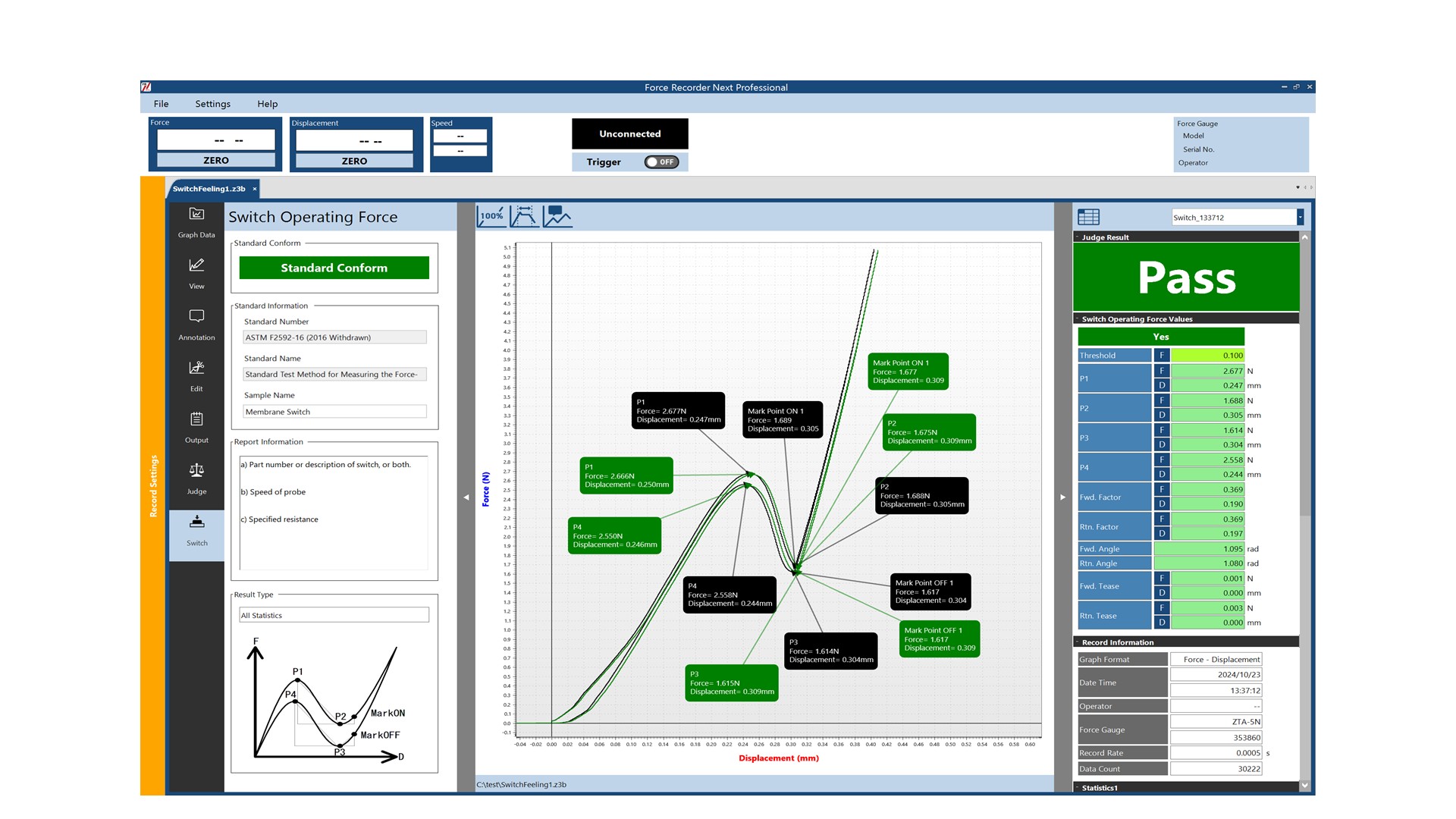

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

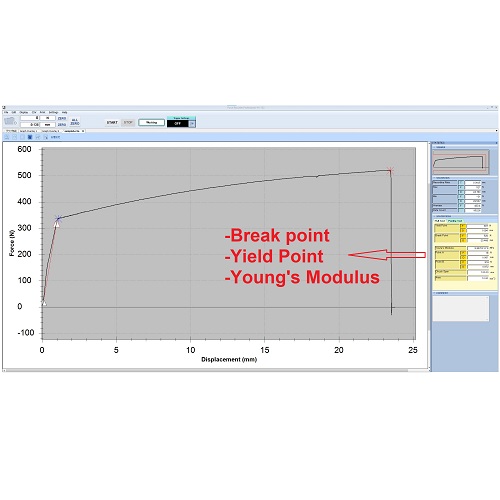

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

Multi-Peak Extraction Function

Multi-Peak Extraction Function

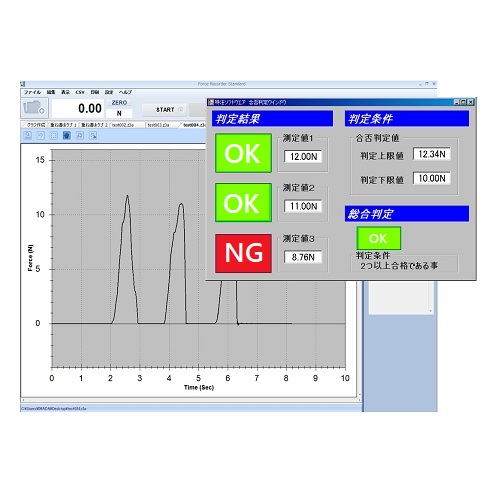

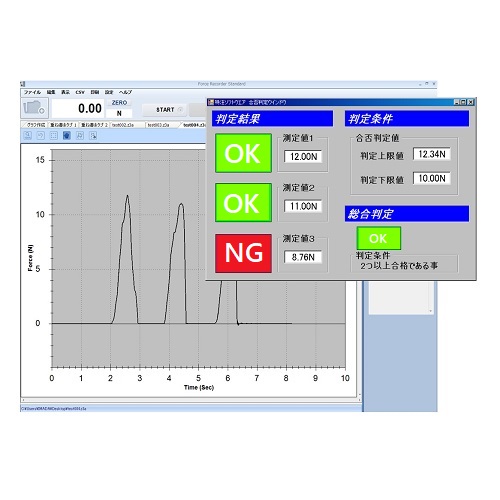

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

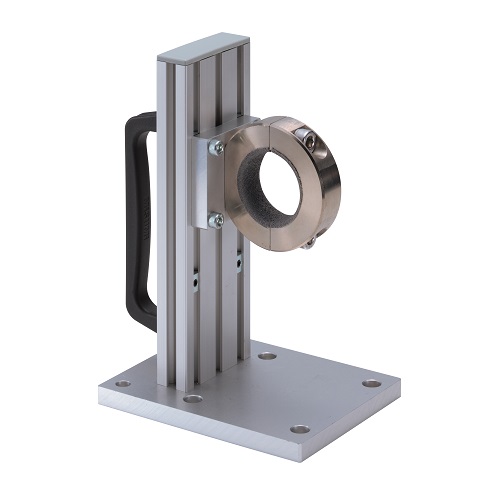

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

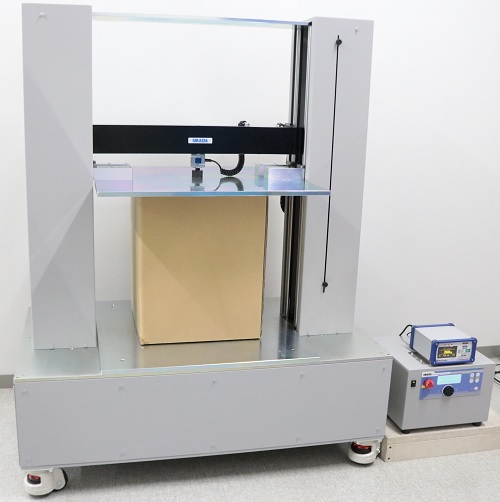

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

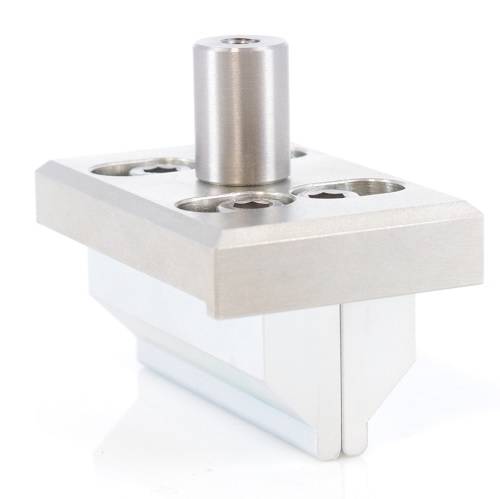

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

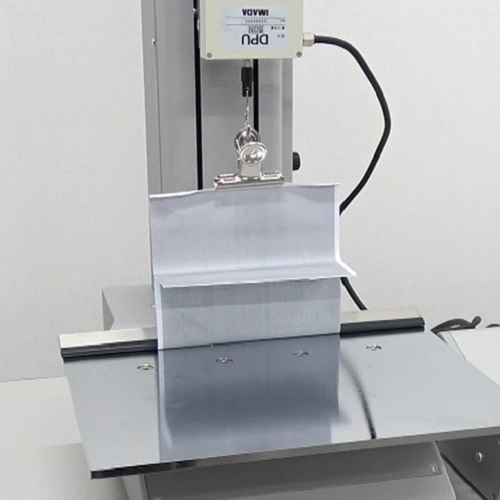

L-shaped Sample Fixture

L-shaped Sample Fixture

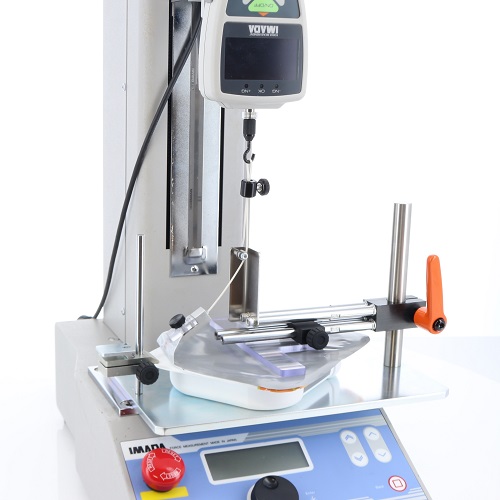

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

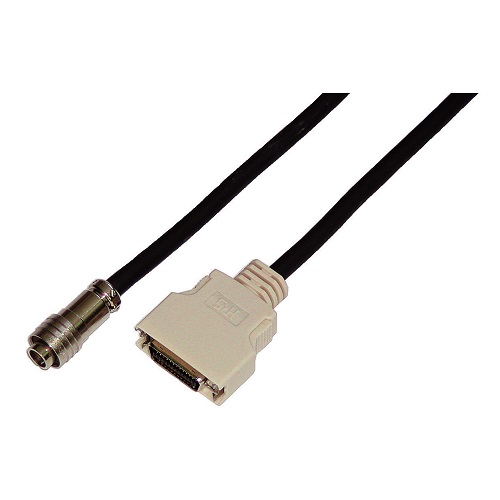

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

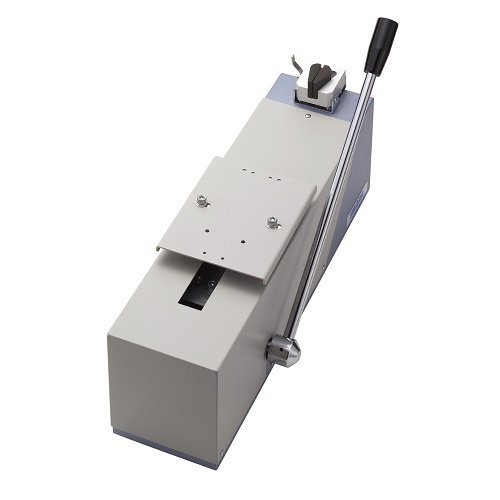

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

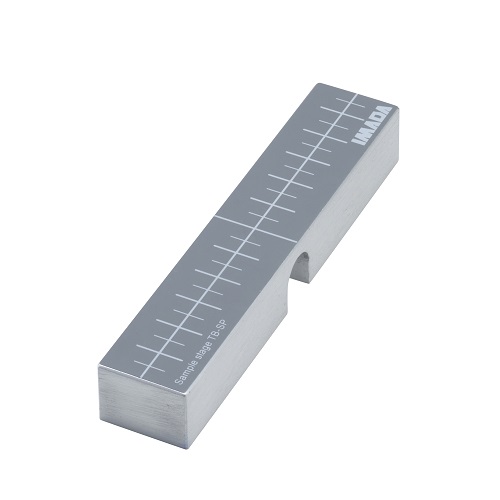

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

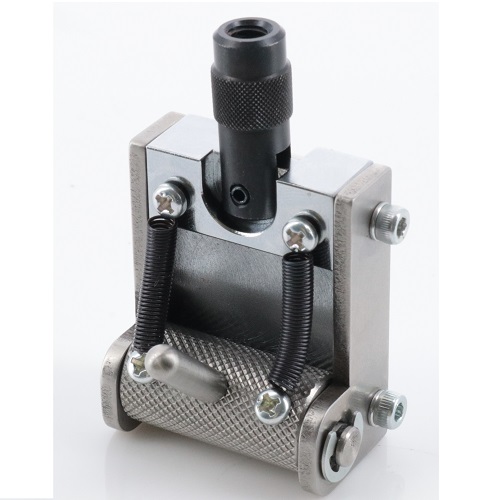

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

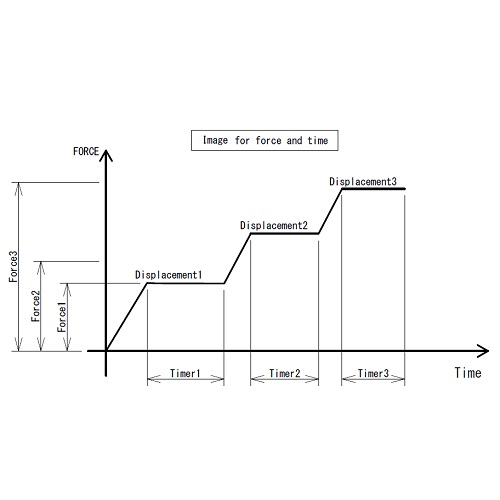

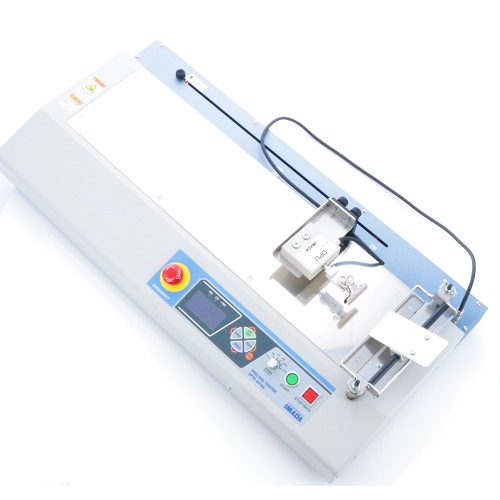

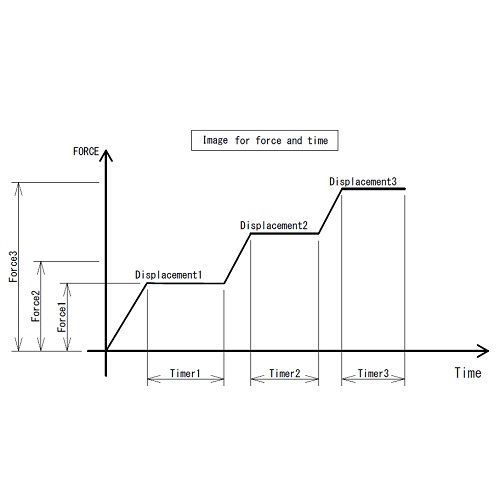

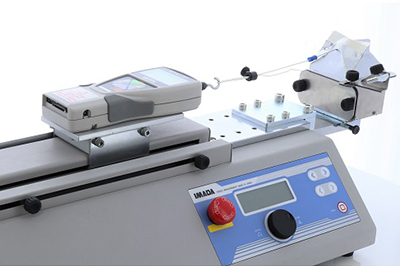

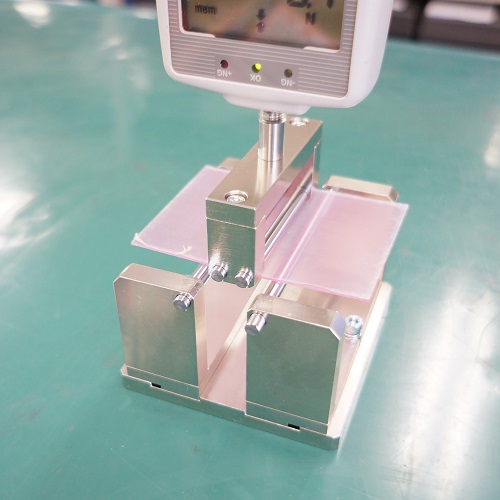

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

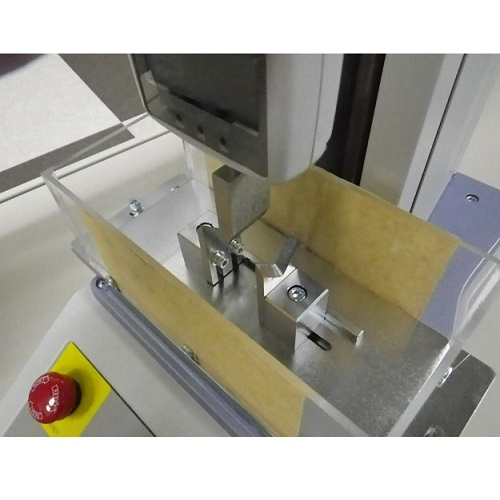

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

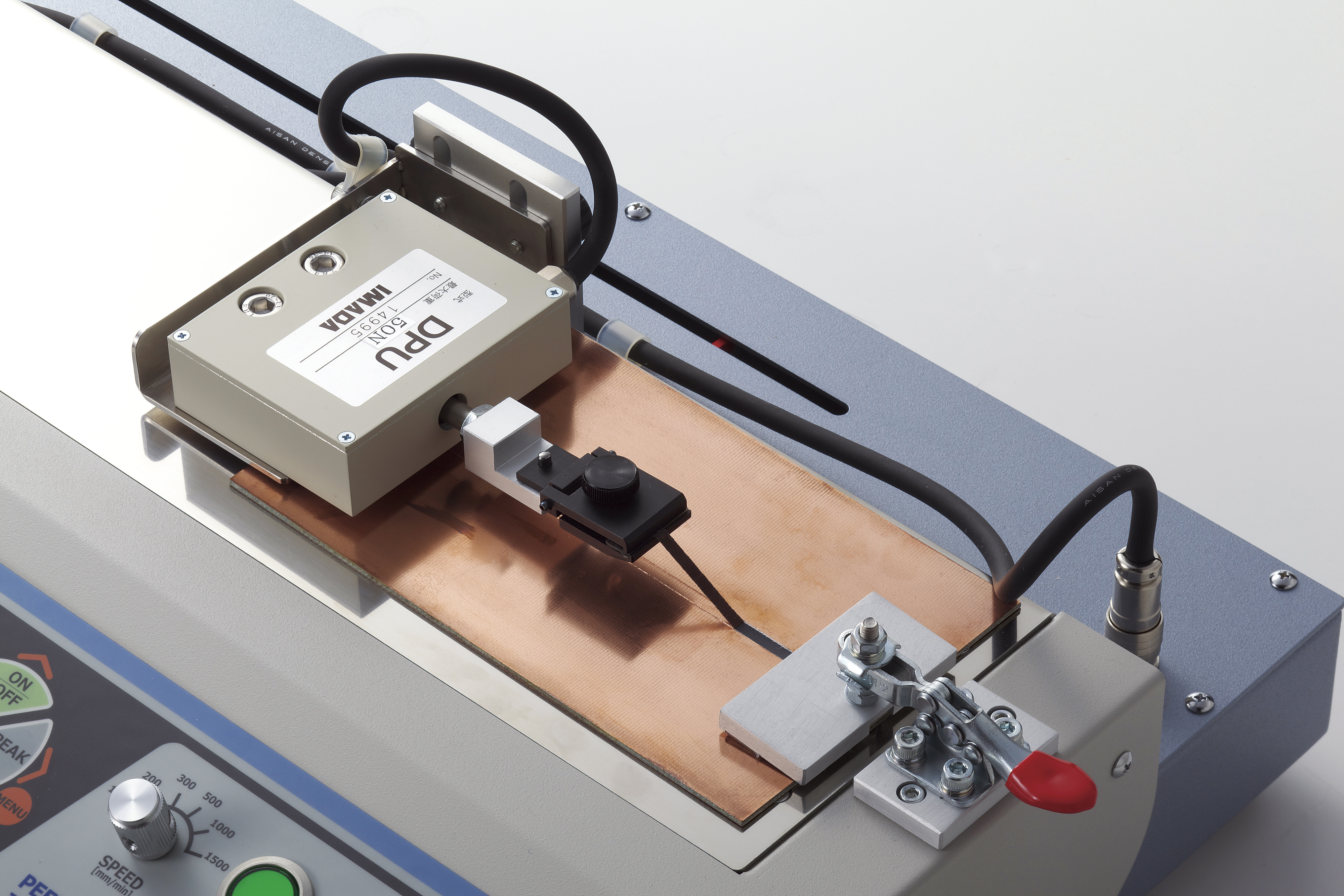

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)