Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

Force Gauge Overview & How to Use

Force Gauges

- Force Measurement IMADA

- PRODUCTS

- Force Gauge Overview & How to Use

Force Gauge Overview

Force gauges, also known as "push-pull gauge" or "push-pull scale" are measuring equipment that measures the load (force) acting on a sample. They can measure tension, compression, bending, shear, as well as peel, adhesion, and friction. They are popular in manufacturing and play critical role in quality control and R&D, such as evaluation of mechanical properties of materials (strength, hardness, toughness, or durability), verification of safety and operability of parts and products, and compliance with industry standards.

Force gauges support our daily lives, such as automobiles, home appliances, food and packaging, medical equipment, stationery, and furniture.

Click here to see the complete lineup of force gauges.

List of all force gauges >

How Best to Select a Force Gauge?

Two main types exist: 1) mechanical force gauges that display measurement results on a scale and 2)digital force gauges that display results in numbers.

1)Mechanicals force gauges feature the ease of storage and management. They are power-source free, durable and easy to use, but are not suitable for impact and rupture tests in which force values change rapidly.

2)Digitals force gauges, on the other hand, feature the ability to manage data by connecting to a PC, and to analyze data by graphing results. They are equipped with both convenient and measurement enhancement functions such as pass/fail test, and continuous peak mode. With a variety of output functions such as serial communication and analog output, they can be connected to and interface with printers and other external devices. The input/output functions can be used for durability test or others in conjunction with displacement measurement, and numerous applications.

Besides types, expected force value and accuracy are important. Selecting a force gauge with a larger force range than the expected force value will prevent damage. Higher accuracy leads to more accurate data management, but requires more maintenance. Check the purpose of measurement and the level of control is recommendable.

We offer selection services tailored to your needs. Contact us.

*Functions of digital force gauges vary depending on the model. Check the specifications on the product page for details.

How to use a force gauge?

Regarding the use of the force gauge, you apply force to the measuring axis (male thread) at the tip of the force gauge, which converts the force into numerical values. When actually measuring, attach the appropriate attachment (fixture) to the measuring axis according to the force you want to measure.

The force gauge can be used simply by hand for easy measurements, or it can be mounted on a test stand to be used as a simple force testing machine. For detailed instructions, please refer to the information below.

How Best to Measure Handheld?

Holding a force gauge by hand and directly pushing or pulling a sample is inexpensive and easy way for force measurement.

Standard models are designed to fit easily in the hand for stable measurement. Optional handles enhance stability. The tilt-sensing alarm functions available on certain models ensures uniform posture conditions and improve repeatability.

*Functions of force gauges vary depending on the model. Check the specifications on the product page for details.

Also check the below video for handheld measurement.

Measure Handheld

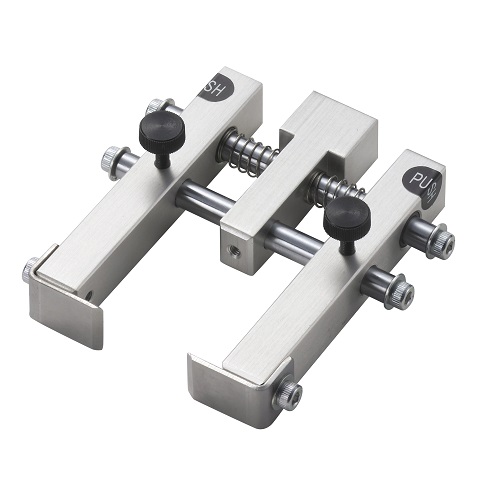

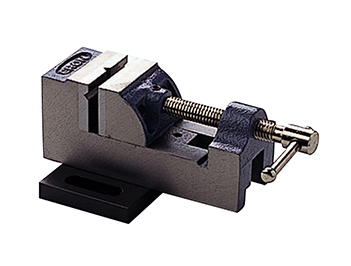

How Best to Mount Attachment to Force Gauge?

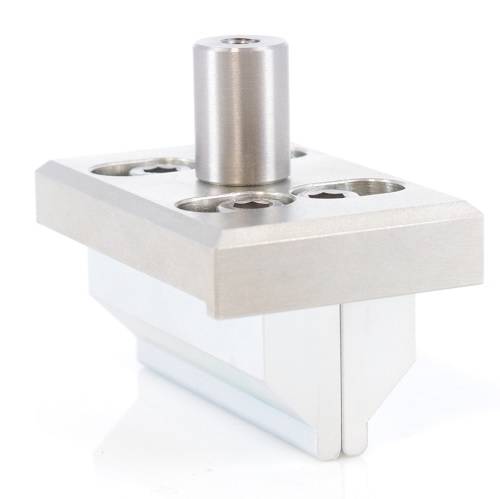

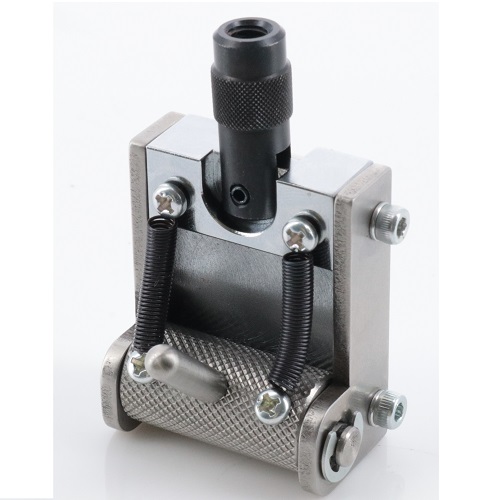

Samples vary in shape or size. Attachments are products that are attached to a force gauge to push or grip a sample. To apply appropriate force, it is important to select an attachment that matches the measurement method and sample shape.

The measurement shaft, the tip of a force gauge, is external thread, and the mounting part of an attachment is internal thread, so it can be attached and detached by turning it around. Replacing attachments is such easy, which helps realizing measurement of various samples.

IMADA offers various attachments. Contact us to help select the appropriate one for your sample shapes or materials.

*Functions and specifications of attachments and force gauges vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of attachments.

List of all attachments

Check the below video for attaching attachments.

Mount Attachment to Force Gauge

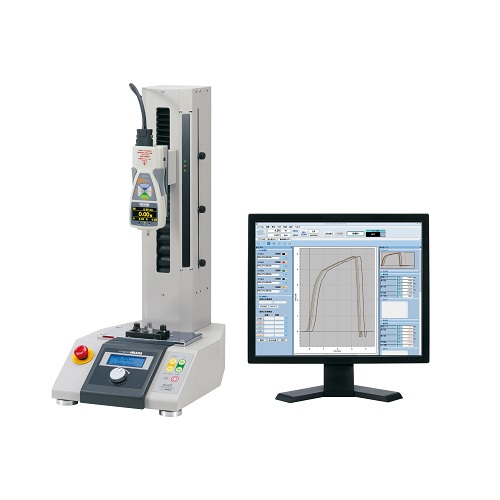

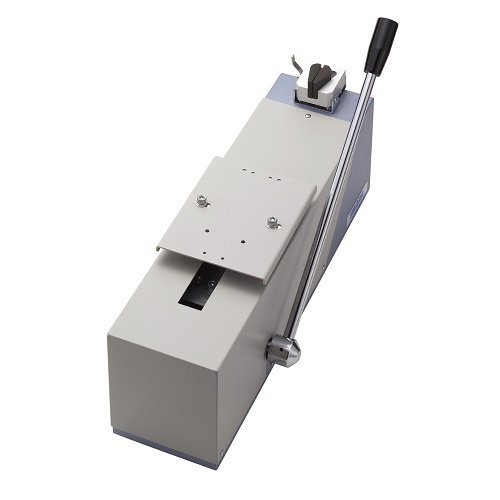

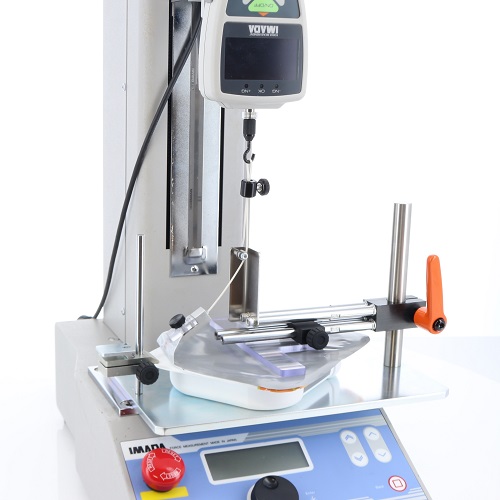

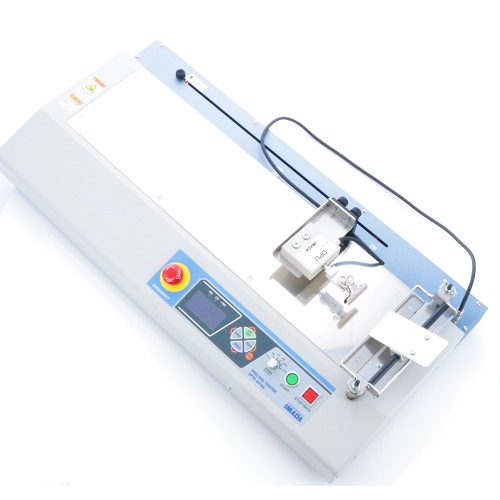

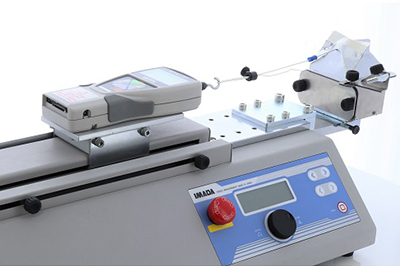

How Best to Measure by Mounting Force Gauge to Test Stand?

By mounting a force gauge to a test stand, the direction and the speed of measurement can be uniformed for highly repeatable measurement. High capacity measurement, which is hard to measure by hand, can be operated easily and safely.

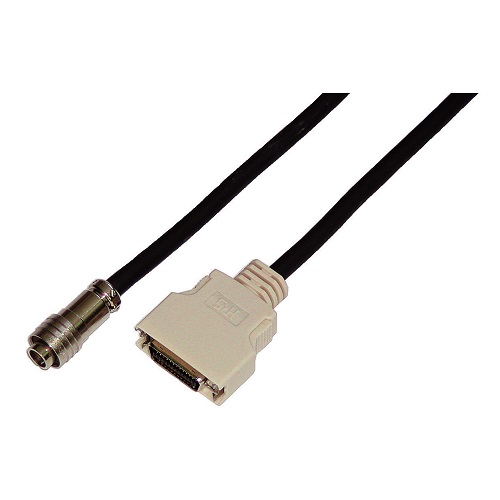

By connecting a force gauge and a motorized test stand via a cable and interlocking them, you can minimize a failure of a force gauge such as overloading, conduct durability tests for a specific time, frequency, or force, and perform compression and rupture tests by detecting contact or rupture points.

*Functions of test stands vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of test stands.

List of all test stands

Check the below video for measurement by mounting a force gauge to a test stand.

Mount Force Gauge to Test Stand

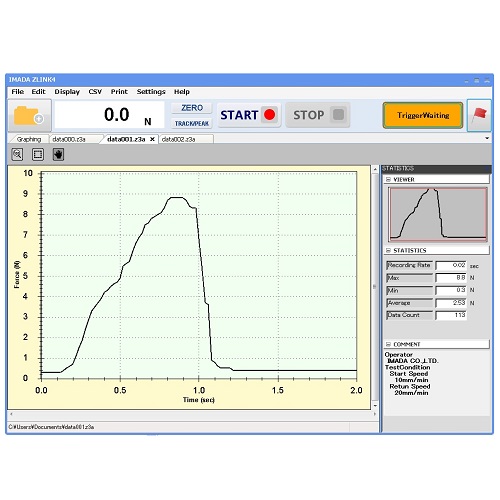

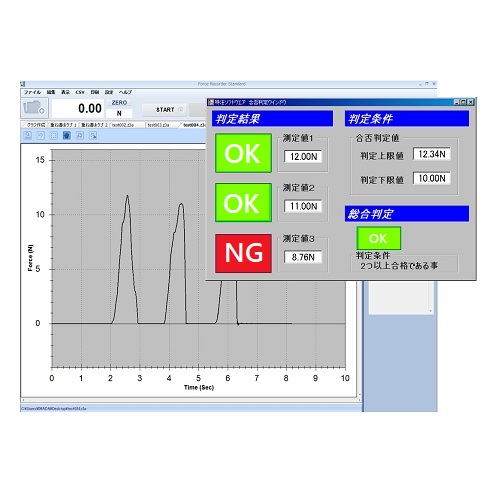

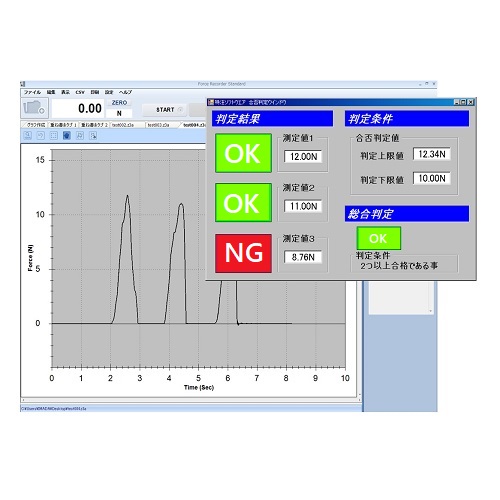

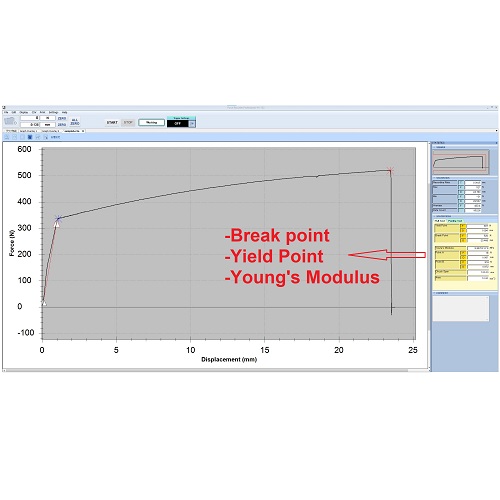

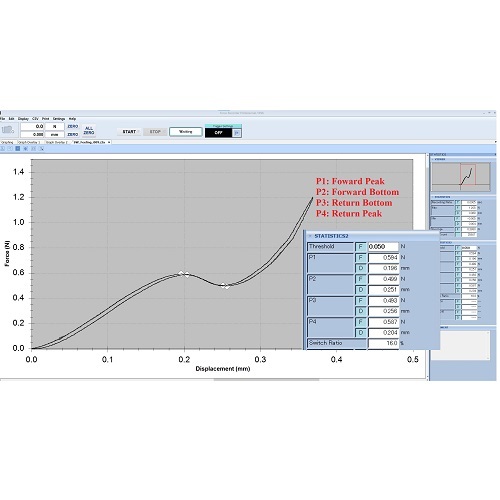

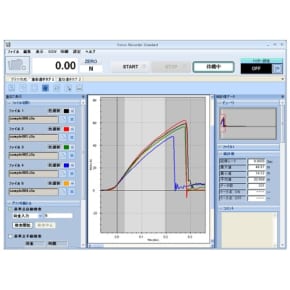

How Best to Draw Force Graph?

Graphing the measured data enables you to check the force transition. The graph visualizes the slope up to the peak and the detection of abnormal force values i.e., foreign matter being caught, which leads to more detailed confirmation of differences in physical properties and quality. The overlap comparison and the magnification function (available in some models) are useful for evaluation, and allow for easy comparison and verification with the previous data.

Besides data saving, various outputs are provided, including printing, PDF, and CSV, which help you to create reports.

The software can be chosen by your needs. Ranging from the acquisition of 2000 data per sec for the creation of precise graphs, the graph creation together with displacement data, to the multi graphing version.

*Functions of software vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of software.

List of all software

Check the below video for the force graph drawing.

Draw Force Graph

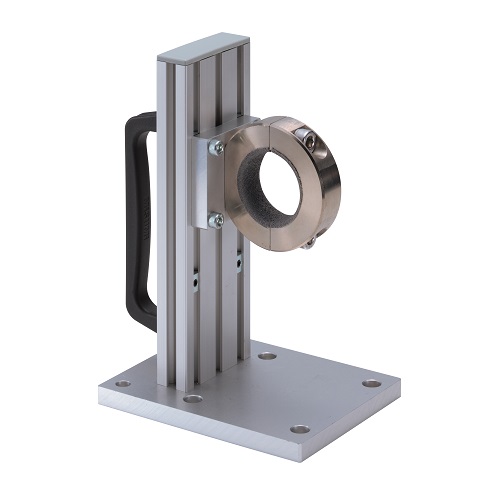

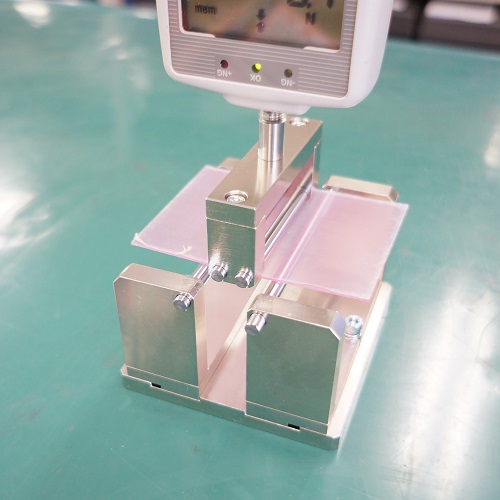

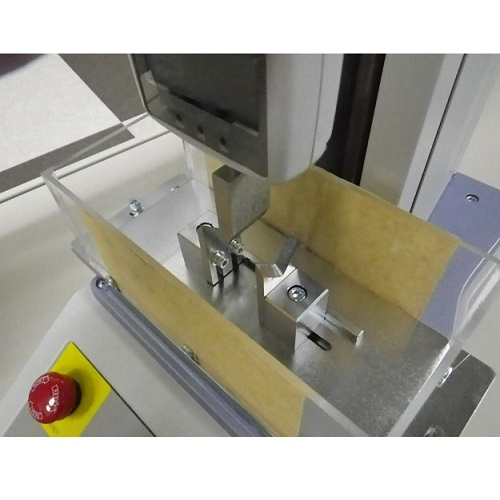

How Best to Connect to Linear Scale Unit?

By connecting a linear scale unit to a digital force gauge with a displacement display function, input/output of displacement becomes possible. It can be used for evaluation of the materials characteristics and quality control, where explained by force alone is not enough, such as the evaluation of repulsive force in response to the amount of pushing or force value at a specific position.

Two types exist: 1)an optional that can be built into a test stand, and 2)a versatile that can be attached to robots or other external systems. Force-displacement graphs can be added by using software.

*Check the specifications on the product page for details of applicable torque stand option and linear scale unit.

Click here to see Force-Displacement Measurement Unit.

Force-Displacement Measurement Unit>

Check the below video for how to connect to linear scale unit.

Connect Linear Scale Unit to Force Gauge

How Best to Extend the Use of Force Gauge?

Digital force gauges feature unique functions.

The Continuous peak mode and the calibration date notification function improve workability and instrument management. The comparator function with upper and lower limit settings simplifies pass/fail judgement, and can be interlocked with external devices to realize warning lights and control by force values using external outputs.

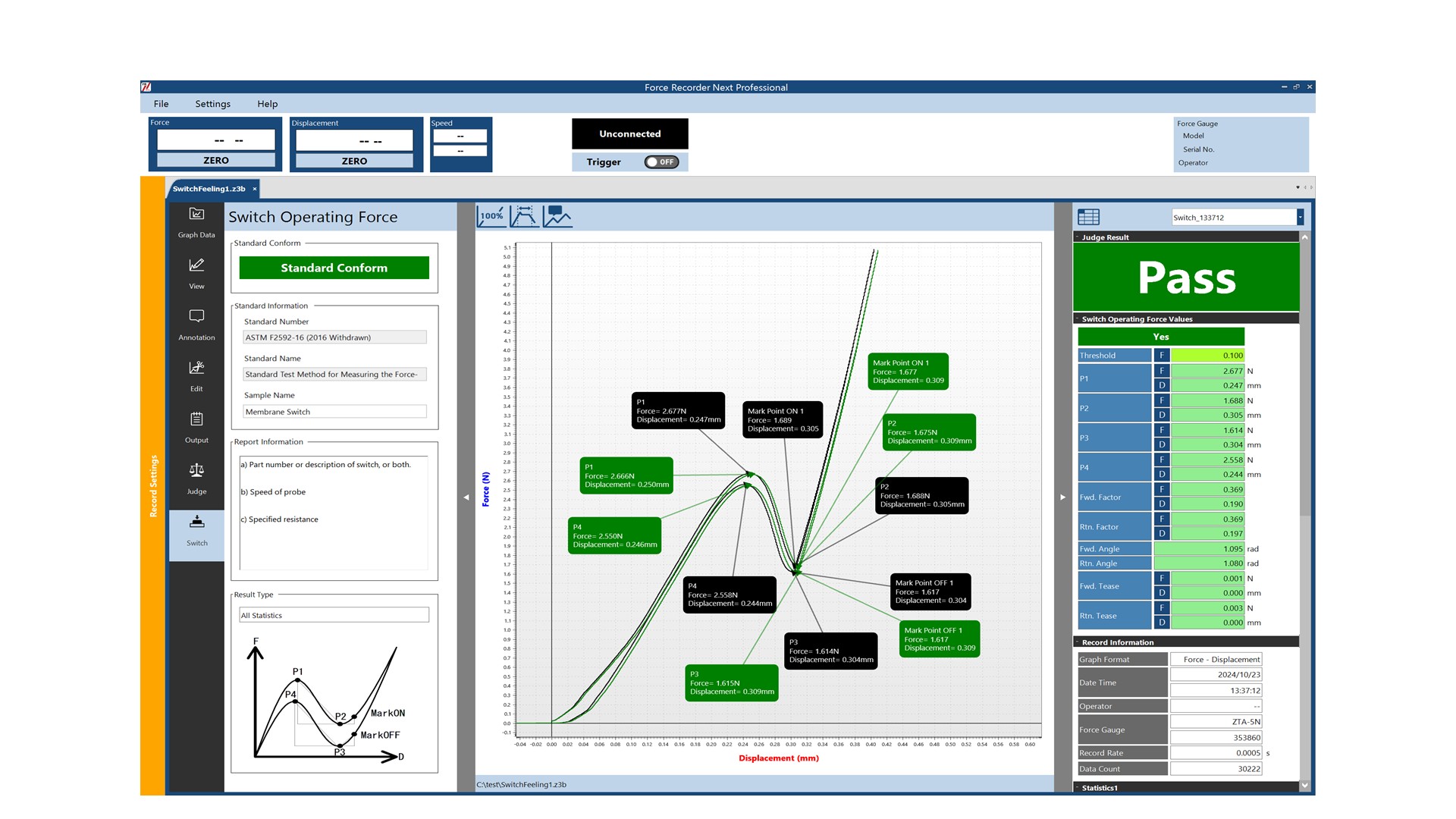

The mark point function records the force values at the contact points of switches and other devices and displays them on a software graph.

Next Series digital force gauges can be upgraded online and download additional functions, i.e., setting and display functions for peel measurement or other various functions.

We assist your effective use of the products via videos or consultation of any subjects. Contact us.

*Functions of force gauges vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of digital force gauges

List of all digital force gauges >

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

Multi-Peak Extraction Function

Multi-Peak Extraction Function

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

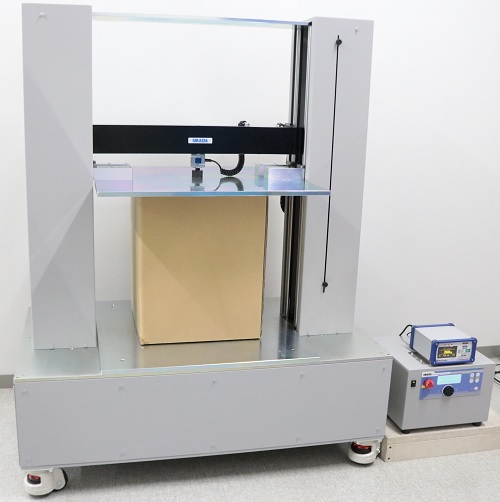

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

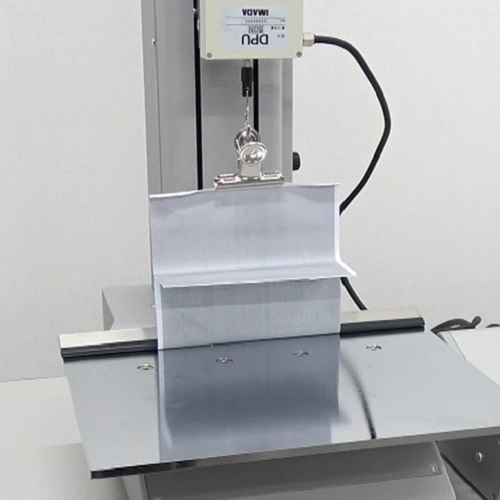

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

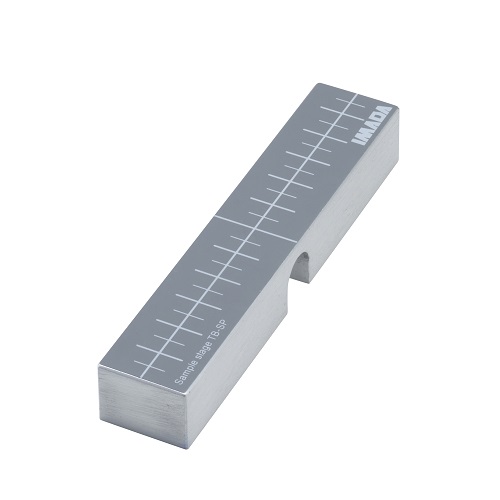

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

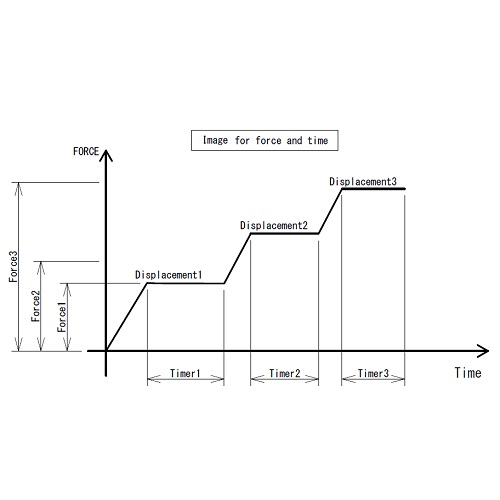

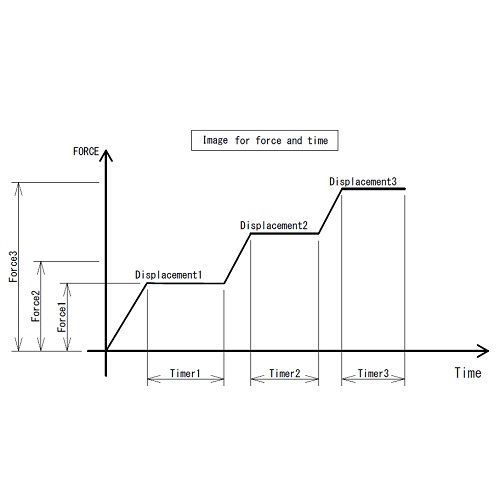

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

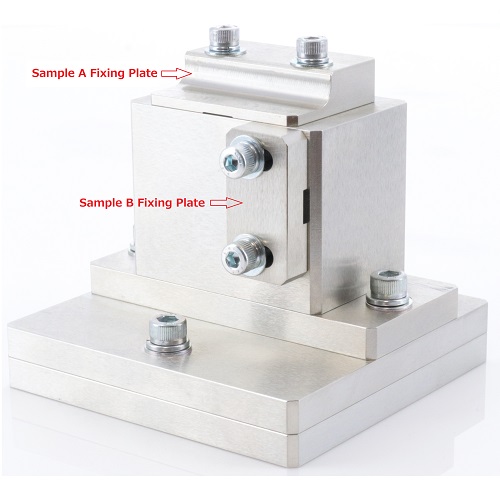

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

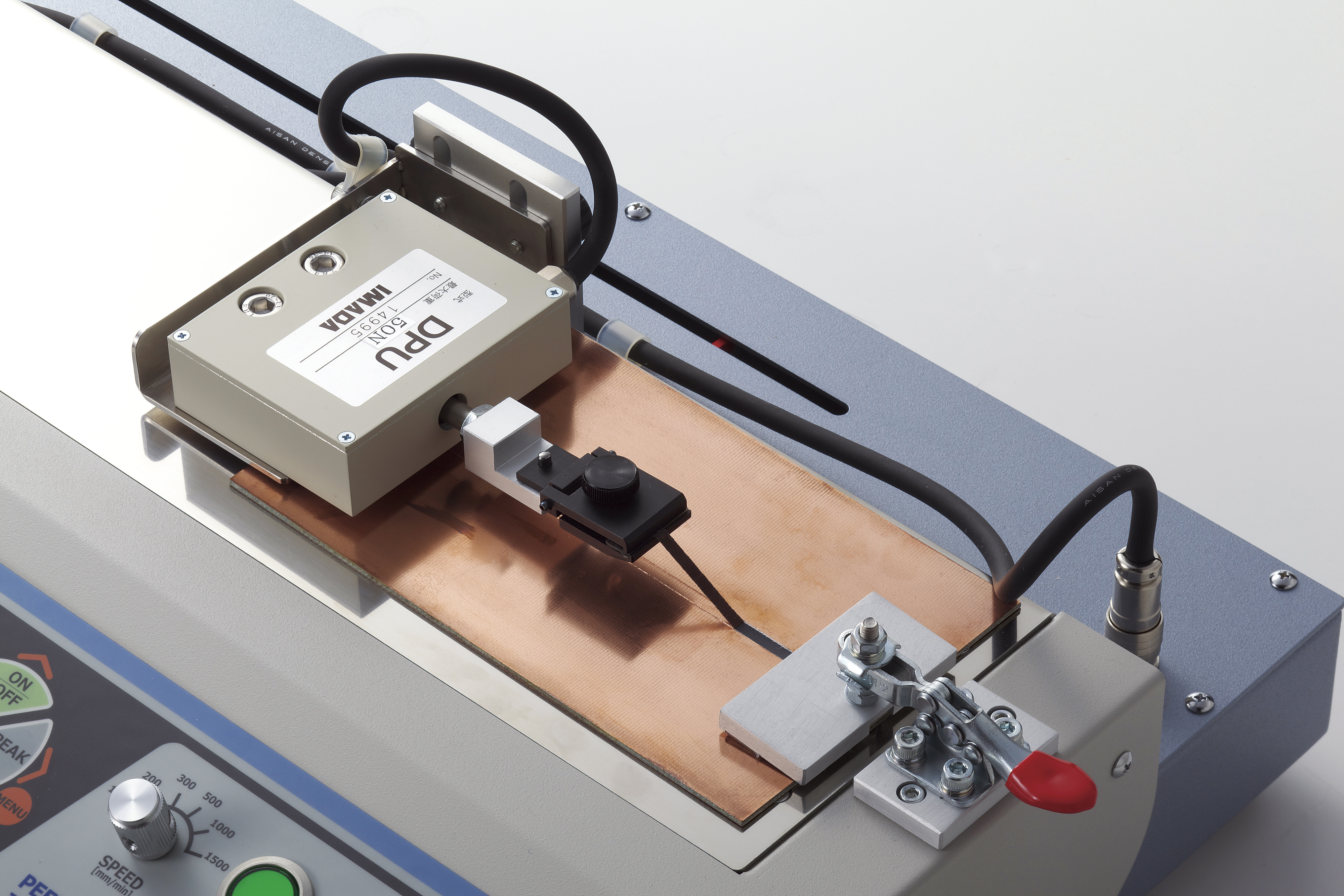

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)