Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

Load Cell Overview & How to Use

- Force Measurement IMADA

- PRODUCTS

- Load Cell Overview & How to Use

Load Cell Overview

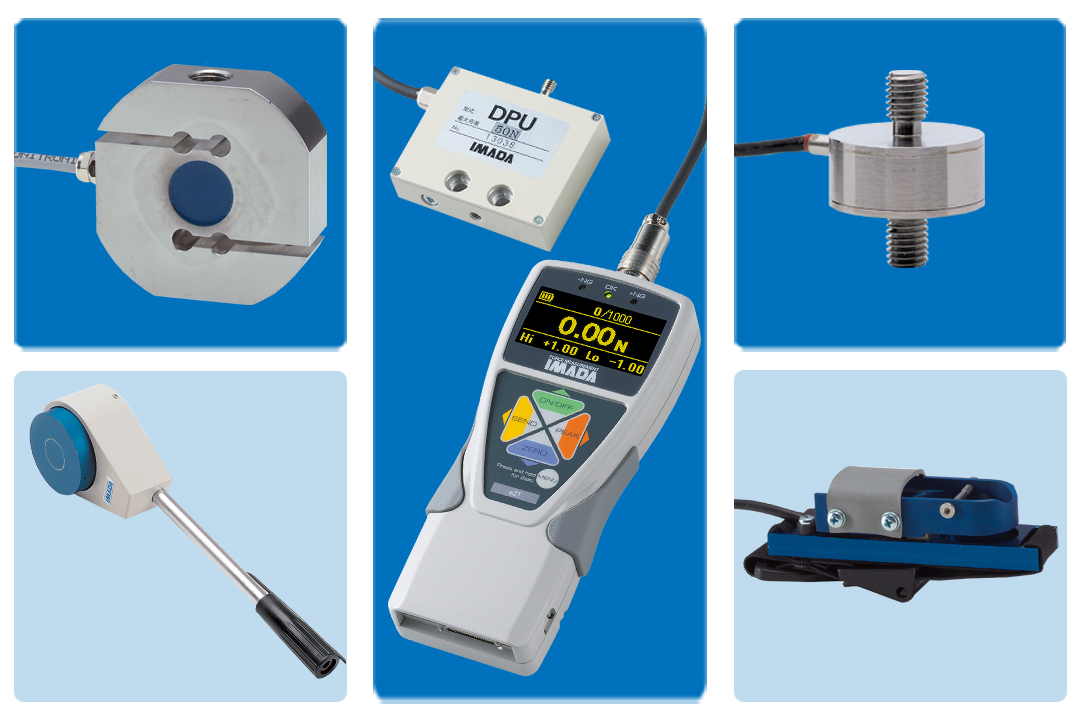

Load Cells, also known as "Load Transducers" or "Load Sensors" are sensor that detects force or torque and converts its magnitude into an electrical signal.

They come in various shapes, such as beam, coin, or S-shape, and can be used for measurement in small spaces or built into specific equipment. There are also particular types with shapes suitable for unique samples such as vehicle handbrakes or footbrakes. Some can be used even in harsh environments such as high/low temperatures, high dust, or exposure to water.

They can be connected to a dedicated amplifier (display unit) to quantify and display the measurement results. Measurement data and pass/fail test value signals can be simply output, allowing for easy management of data, and interlocking of measurement results with equipment.

Although they are rarely seen in everyday, they are used in a variety of production facilities as fundamental. They support our daily lives, i.e., in the form of strength test and operability evaluation of automobile assembly parts and finished car bodies.

Click here to see the complete lineup of load cells.

List of all load cells >

How Best to Select Load Cell

There are five considerations.

1)Shape. Important to use a load cell with a fixing method and size suitable for the measurement space and sample. For example, coin-shaped are small and thin and can be inserted into narrow gaps, making them ideal for measurements in tight or unstable spaces.

2)Measurement Direction. Some are dedicated for compression or tension only, so it is necessary to confirm whether they can handle the measurement you want to make.

3)Measurement Environment. If you want to use them in an environment with restrictions such as temperature, you need select an appropriate type.

4)Maximum Force Value. Selecting a range higher than the expected force value will prevent damage. Especially in the case of frequent force loading, such as in equipment that is constantly in operation, selecting a range with a large margin will increase durability and lead to stable operation. You may also anticipate unintentional large forces, so it is recommended to select a range with a sufficient margin.

5)Measurement Accuracy. The accuracy of the combination of load cell and indicator depends on the type of indicator, and should be selected according to the measurement requirements. Higher accuracy leads to more accurate data management, but it also increases the labor, and difficulty of maintenance.

We offer product selection services tailored to your needs. Contact us.

*Functions and specifications of load cells and amplifiers vary depending on the model. Check the specifications on the product page for details.

How Best to Integrate Load Cell

Load cells can be integrated to facilities or external equipment to measure forces applied in the compression or tension direction, enabling force monitoring in production lines, process control, and finished product inspection.

Unlike force gauges, load cells are separated from the display unit, making them suitable for use in tight spaces. Rectangular shape is ideal for integration, and its structure is easy to fix with screws, making it easy to integrate into facilities or external equipment. IP-compliant (Ingress Protection) load cells can be deployed in harsh environments.

*Specifications of load cells vary depending on the model. Check the specifications on the product page for details.

How Best to Measure Handheld or Foot-Operated

Load cells can be held by hand and placed between samples, pushed directly, pulled, or rotated. You can also measure by stepping on the load cell with your foot. This is useful for measurement where force is actually applied to the sample using the hands or feet, and the sensation of the force is quantified, or when the sample is difficult to move, such as a finished product.

*Check the application videos on each product page to gain ideas how to measure by holding the load cell with hand or stepping on it with foot.

*Some torque load cells require an attachment (sold separately). Check the specifications on the product page for details.

Load Cells for Specific Applications

We offer specialized load cells for specific applications. Load cells for automatic and revolving doors is one example, which can be used for daily safety inspections in compliance with standards. Besides, there are various types such as crane scale type to meet a variety of force measurement needs.

*Check the specifications on the product page for details.

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

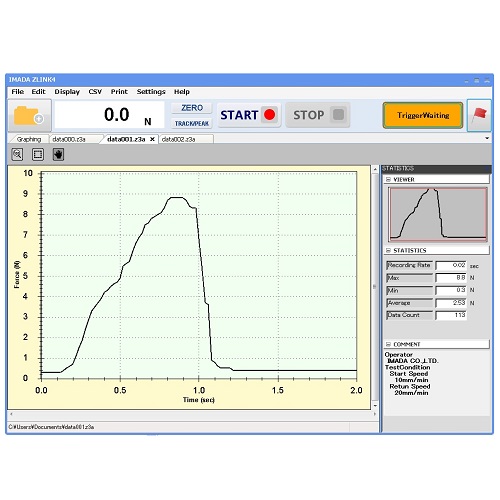

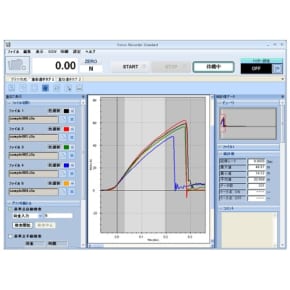

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

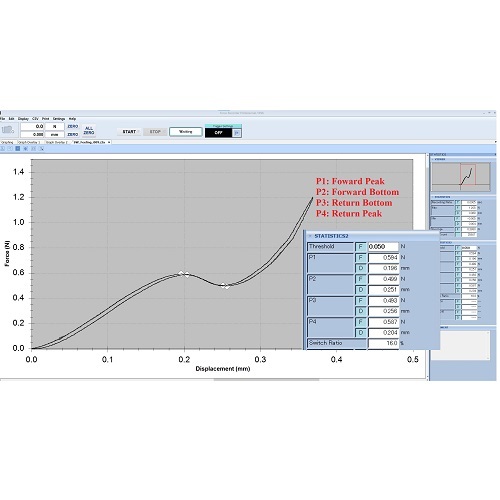

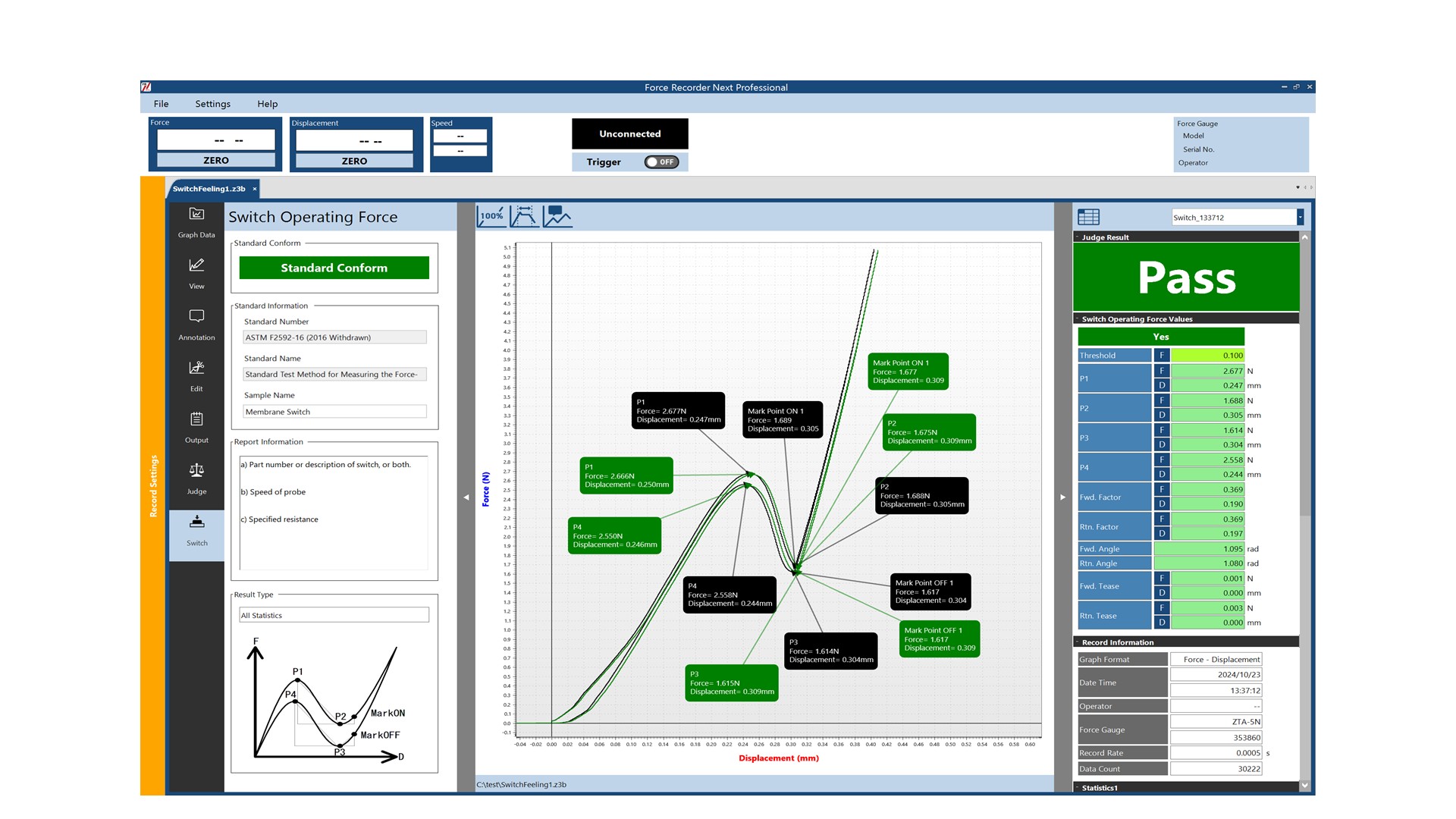

Switch Operating Force Testing Module

Switch Operating Force Testing Module

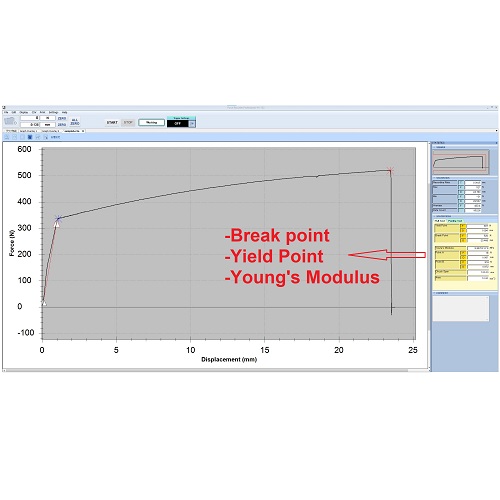

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

Multi-Peak Extraction Function

Multi-Peak Extraction Function

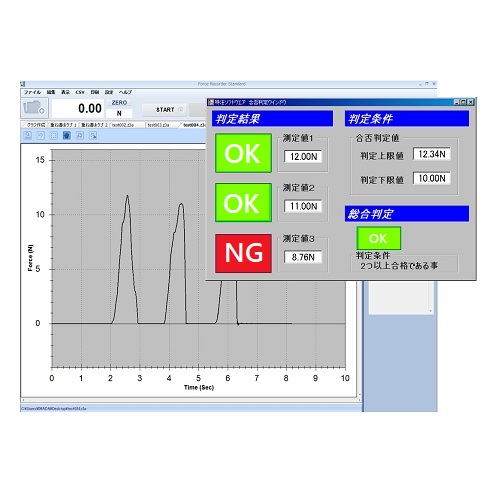

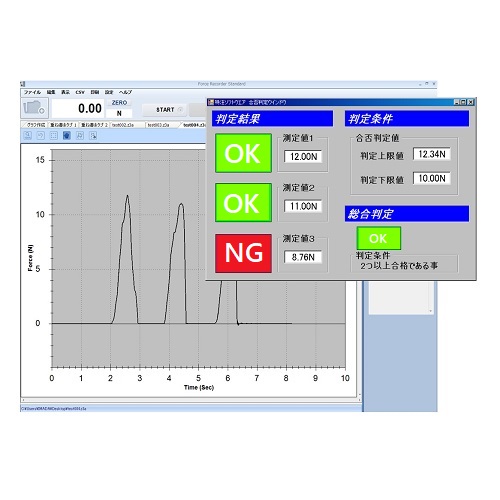

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

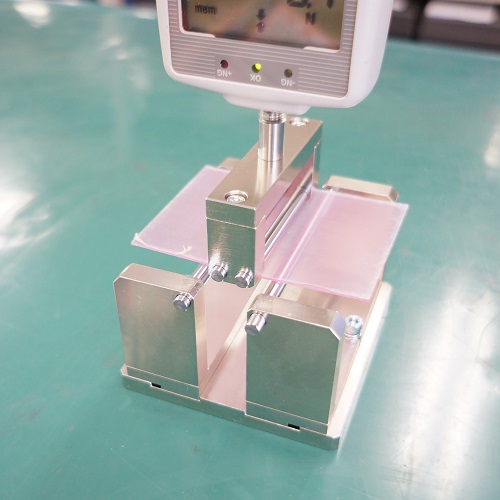

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

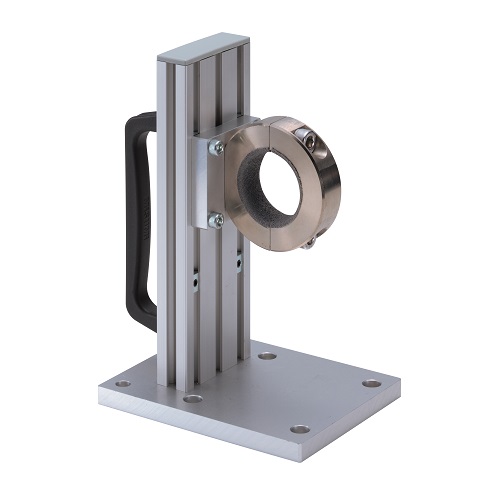

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

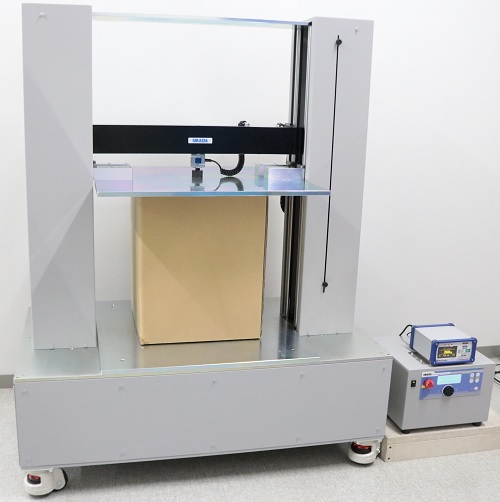

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

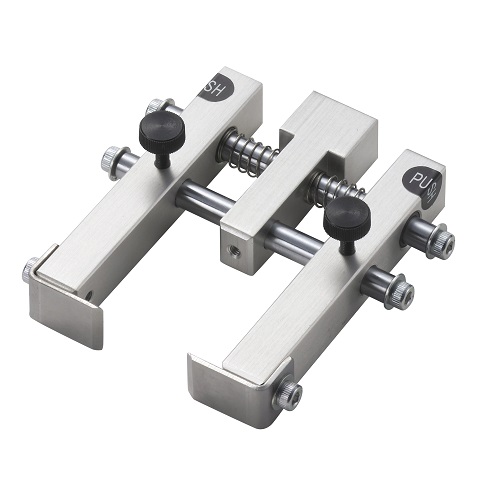

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

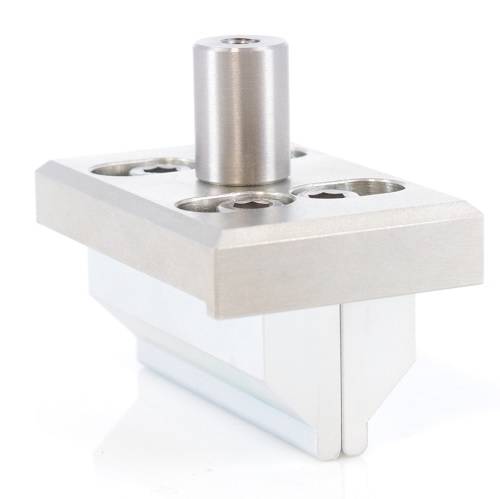

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

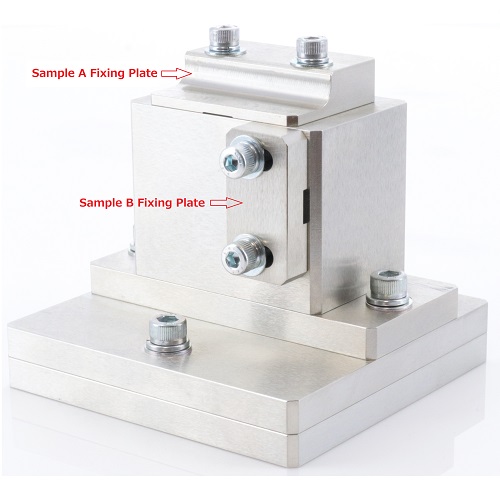

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

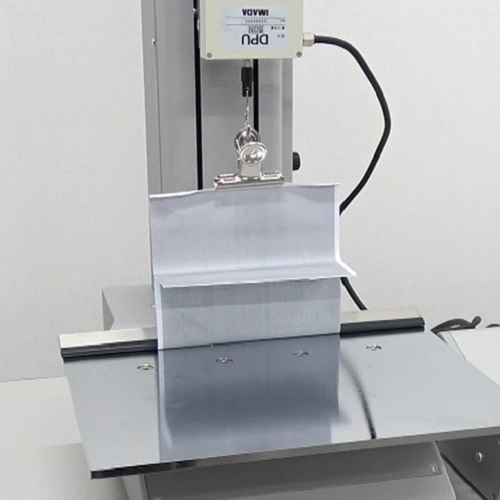

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

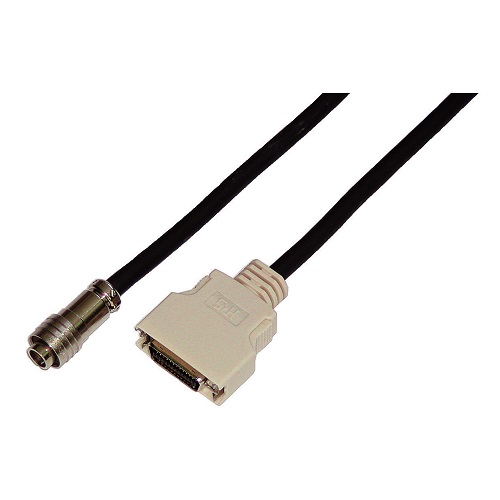

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

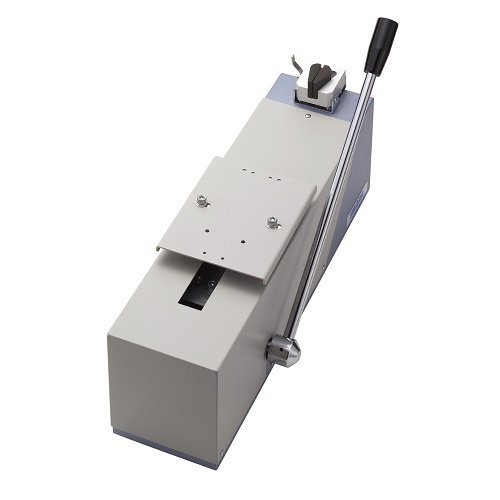

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

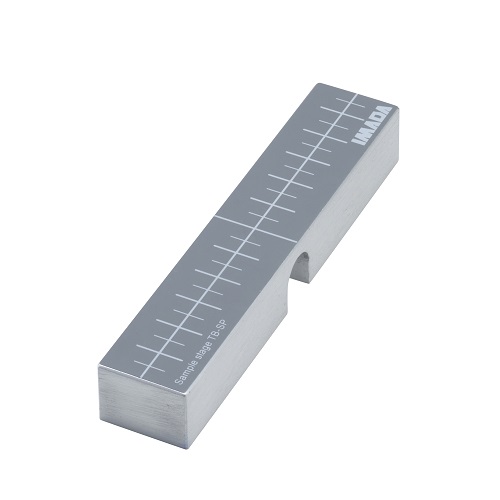

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

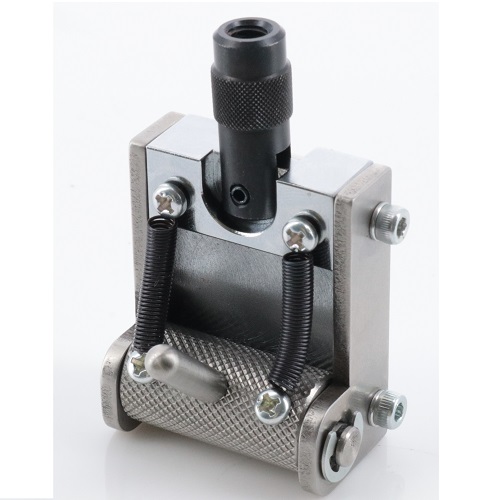

Cam grip with spring

Cam grip with spring

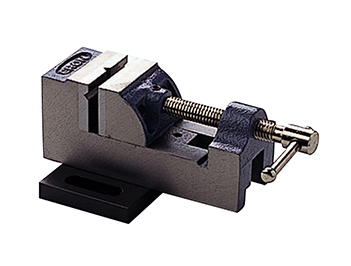

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

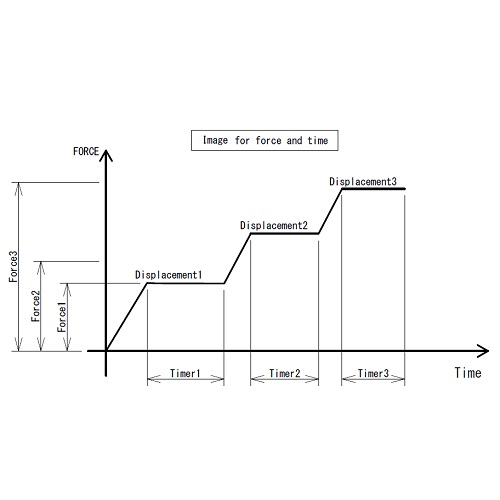

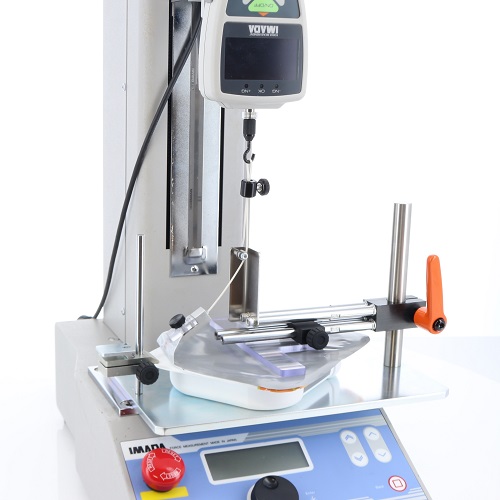

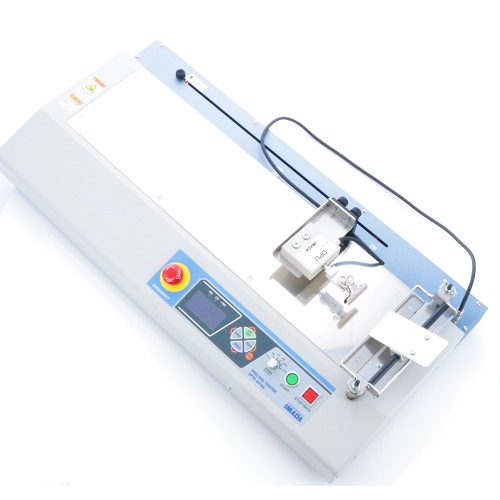

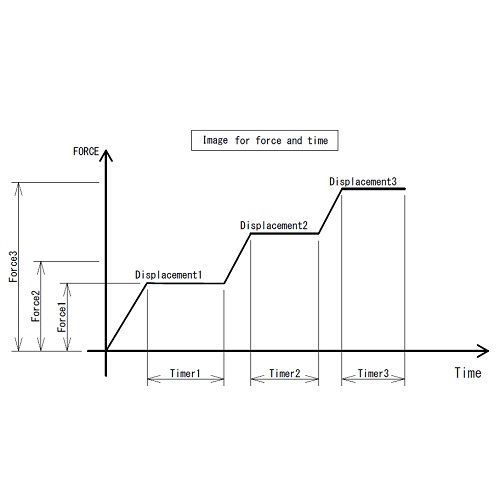

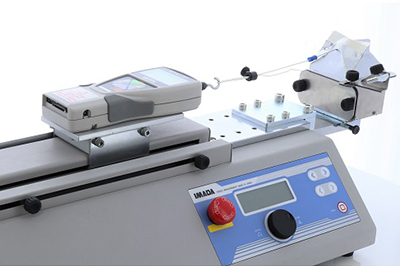

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

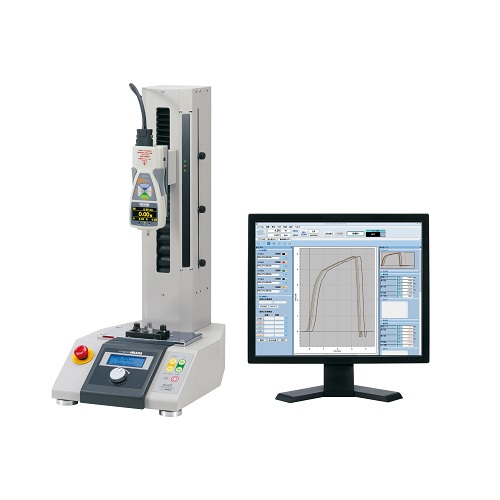

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

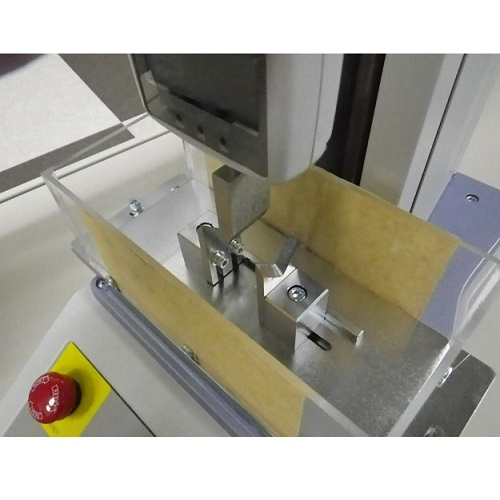

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

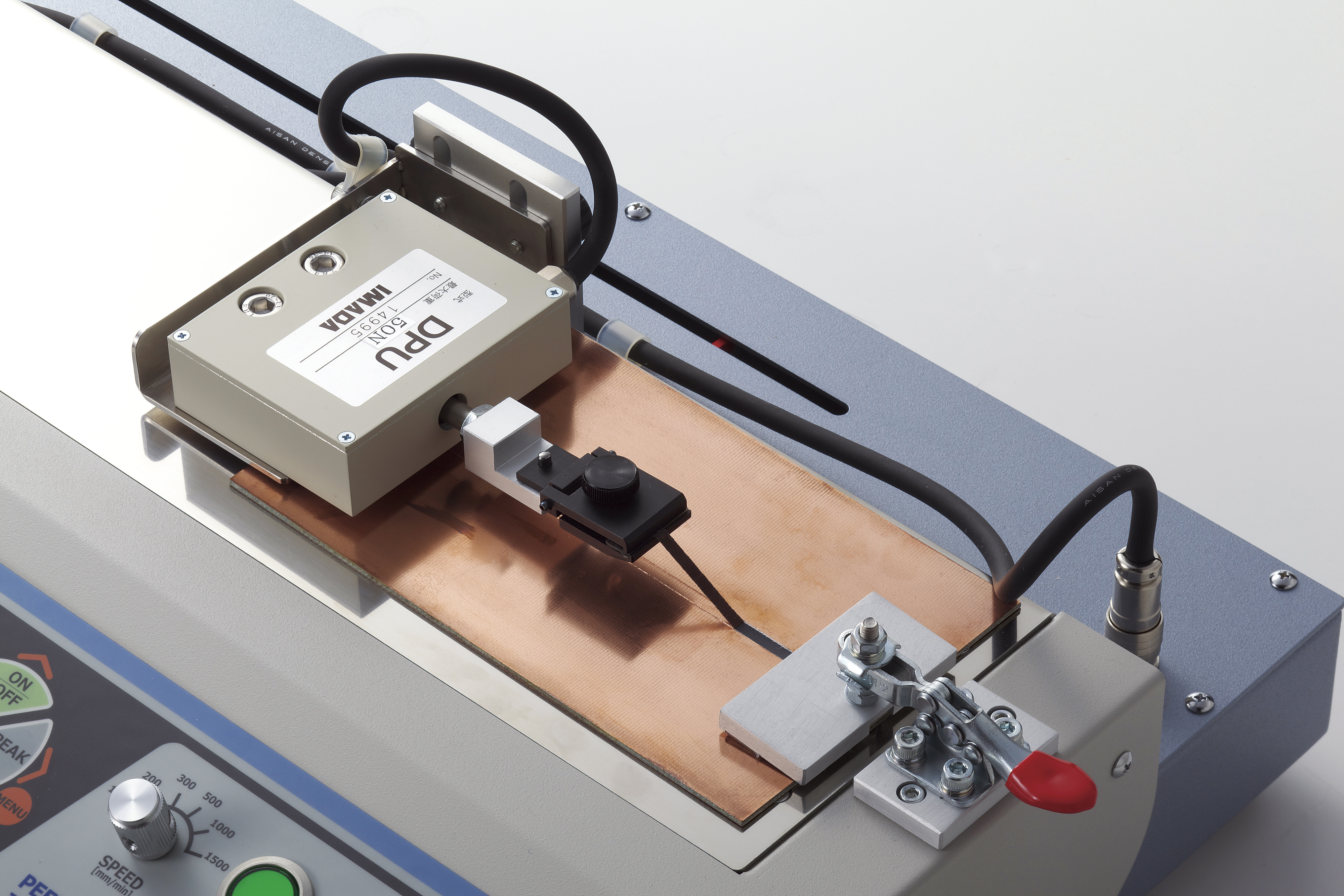

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)