Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

Torque Tester Overview

Torque Testers

- Force Measurement IMADA

- PRODUCTS

- Torque Tester Overview

Torque Gauge Overview

Torque is the torsional moment (turning or twisting force) that acts on an object when it rotates, and the device that measures torque is Torque Tester. Torque testers can be used to measure opening and closing force, turning force, and sliding resistance, and indicate them in the unit of N-m, N-cm, kgf-m, kgf-cm, lbf-in, or ozf-in .

Torque measurement is popular, from the torsional strength of circuit boards, the tightening force of screws, the opening force of PET bottles and jars, and the operating force of rotary switches and keys, as a few examples. ( See usage examples of torque gauges > )

Also commonly used to evaluate the safety and the operability of such parts and products, conform to industry standards. It is one of the most important measuring instruments supporting quality control and research and development.

Click here to see the complete lineup:

List of all torque gauges (torque testers) >

How Best to Select Torque Tester

There are three main types: 1) the desktop, in which the sample is fixed to a table and turned by hand for measurement, 2) the handheld, in which the sensor is held in hand and the sample is held by an attachment for measurement, and 3) the buit-in, in which the sensor is integrated to equipment for measurement.

The desktop type tprque meter is most suited for measuring the opening and closing torque of container lids such as PET bottles and jars. By changing the attachment (table), samples of many sizes and shapes, such as small parts and cosmetic containers, can also be measured.

The handheld type torque gauge is ideal for torque measurement of tightening and loosening force of screws and bolts, rotary switches, and so on. By changing the attachment, samples of many sizes and shapes, such as volume knobs and keys, can also be measured. The handheld torque gauge is also portable and suitable for measuring a part of finished products.

The buit-in type torque gauge is ideal for integration to torque testers or torque control systems in production line for torque measurement. It is also suitable for measurements in limited space due to the small sensor.

To select the suitable type, you may consider whether you bring the sample to be measured(desktop), take the torque gauge to the sample location to measure (handheld), or integrate to equipment to measure(buit-in), depending on the measurement environment.

The maximum torque value is also important in selection. Selecting a range larger than the expected torque value will prevent damage to the torque gauge. In addition to standard types, both desktop and handheld are available in high-performance types with convenient functions such as angle input/output and 2-step peak acquisition, which expand the level of measurement.

We offer selection services to meet your need. Contact us .

*Specifications of force testers vary depending on the model. Check the specifications on the product page for details.

How Best to Measure Handheld

Handheld torque measurement can be performed easily and suited to your budget by turning a sample fixed to the torque gauge by hand, or by holding and turning/twisting a sensor with a sample fixed on an attachment. There are two types: 1) Handheld and 2) Desktop.

1) Handheld is designed to fit easily in hand and provide stable measurement.

2) Desktop provides easy and stable sample fixation. The sample can be quickly set, and therefore repeated measurement can be performed efficiently.

Constructed with a double bearing support mechanism in the sensor section to minimize the effects of lateral and bending forces, it enables precise measurement even though the measurement is done handheld.

Handheld measurement is ideal for measuring torque imitating human motion.

For example, when a person tries to open a lid, they do not use a constant force from the beginning, but rather controls the grip force unconsciously, such as gradually increasing the force while turning it or loosening it when it starts to open.

If the lid is easily deformable, a stronger grip will increase resistance and change the torque value. By measuring by hand, it is possible to measure the torque required for a person to open a bottle by hand, including such factors.

For more precise measurement, such as when evaluating the uniformity of multiple samples, use in combination with a torque stand to improve measurement repeatability.

*Functions and specifications of torque gauges vary depending on the model. Check the specifications on the product page for details.

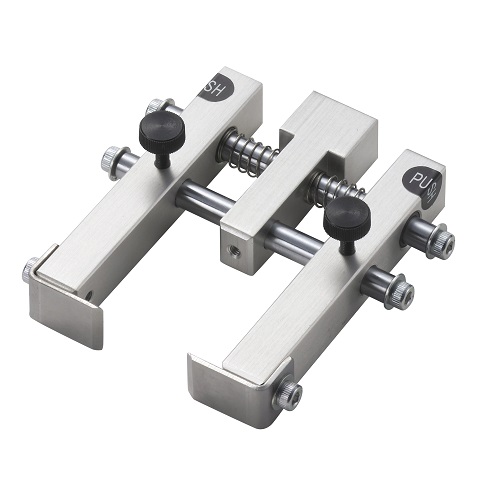

How Best to Attach Attachments to Torque Tester

Samples come in various shapes and sizes. Torque attachments are used to attached torque testers or torque stands to fix samples. It is important to select attachments that match the measurement method and shape of samples in order to apply the appropriate force.

Two main patterns of attachment mounting exist.

1) Fixing to screw cap tester-DTXS/DTXA series

Simply fit the groove on the shaft of the attachment to the sensor part.

2) Fixing to HTGS/HTGA series hand-use digital torque testers

Align the pin on the tip of the sensor with the groove on the attachment, insert it, and turn the set screw on the attachment to fix it in place.

In either case, the attachment can be easily fixed and detached, allowing efficient measurement of different samples.

Also note that attachments are available for different models, and proper attention is required when selecting one.

We can assist you in selecting the appropriate attachment for your sample shape and material, as well as for selection in combination with a torque gauge. Contact us.

*Functions and specifications of torque gauges and torque attachments vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of torque attachments.

List of all torque attachments

Check the below videos to see how to attach the attachment.

Mount Attachment to DTXS/A series

Mount Attachment to HTGS/A series

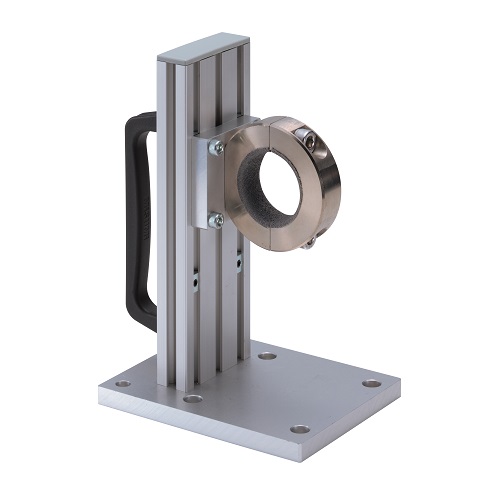

How Best Attach Torque Tester to Torque Stand

By combining a torque tester or attachment with a torque stand, a more precise measurement can be achieved. Although the method of attaching a torque tester to a torque stand differs depending on the model, the procedure is simple and mainly consists of one of the three ways.

1) Fix screw cap torque tester DTXS/DTXA series

Remove the screw from the handle and attach it to the torque stand using the screw hole. For motorized torque stand, a centering jig is included to allow easy centering and installation for more accurate measurement.

2) Fix handheld digital torque meter HTGS/HTGA

Fix the sensor part to the sensor holder part with screws.

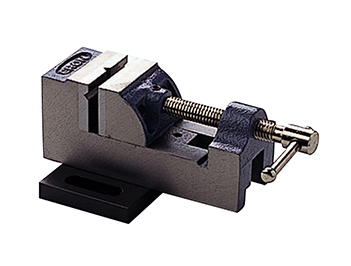

3) Fix the measurement sample

Use the attachment to fix the measurement sample. It is either inserting the attachment and fixing it with a pin, aligning the grooves of the attachment and inserting it, or fixing it with a set screw.

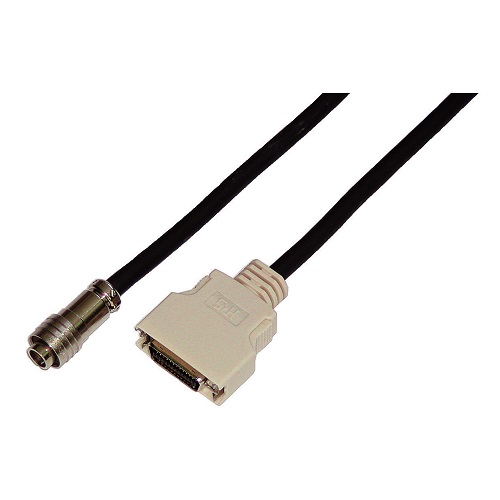

Torque stand and torque tester can be connected by a cable. Finally, fix the sample and set up the stand as necessary for testing. These installation procedures are simple and can be easily performed by one person.

*Specifications and procedures vary depending on the model. Check the specifications and user guide videos on the product page for details.

Click here to see the complete lineup of torque stands.

List of all torque stands>

Check the below video for mounting to various types of torque stands.

Mount Torque Tester to Torque Stand

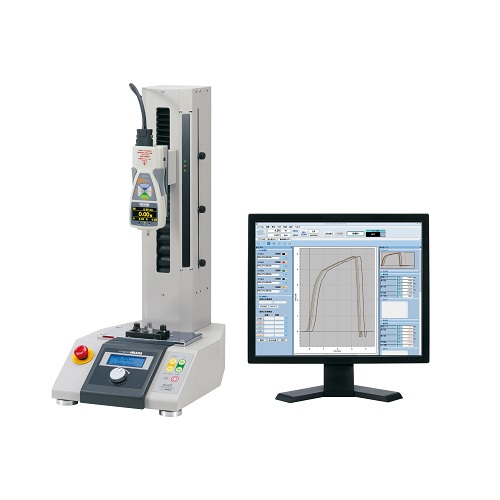

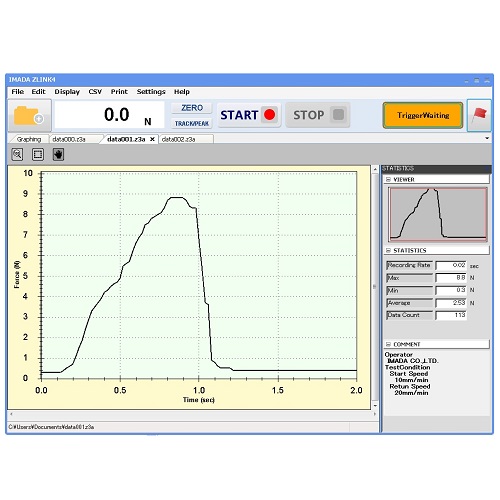

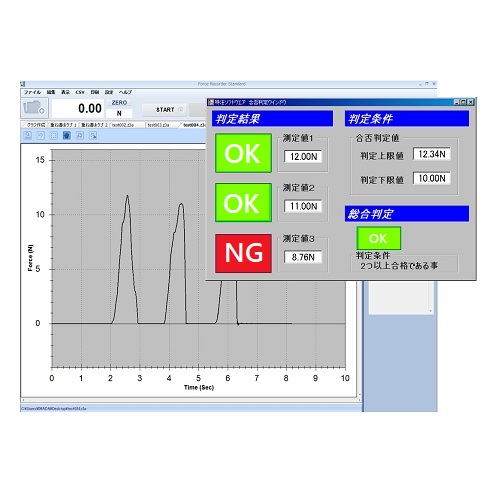

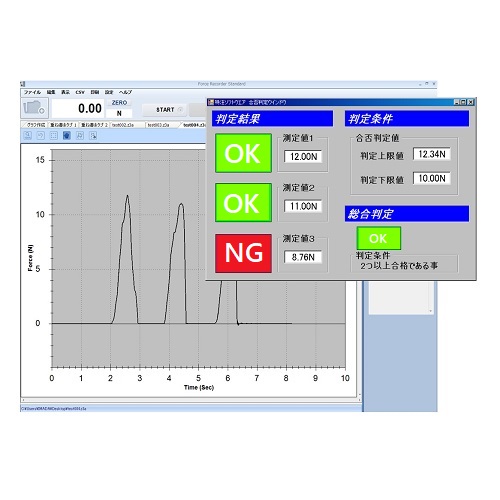

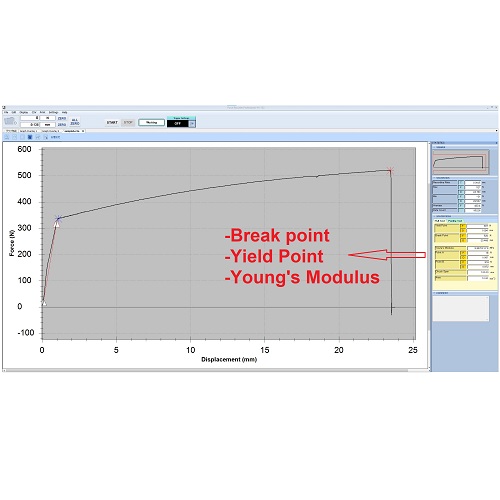

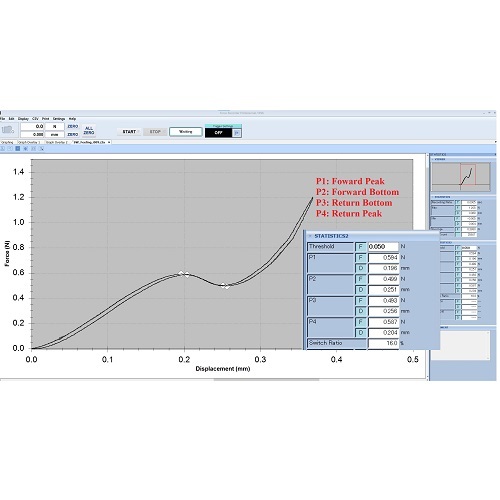

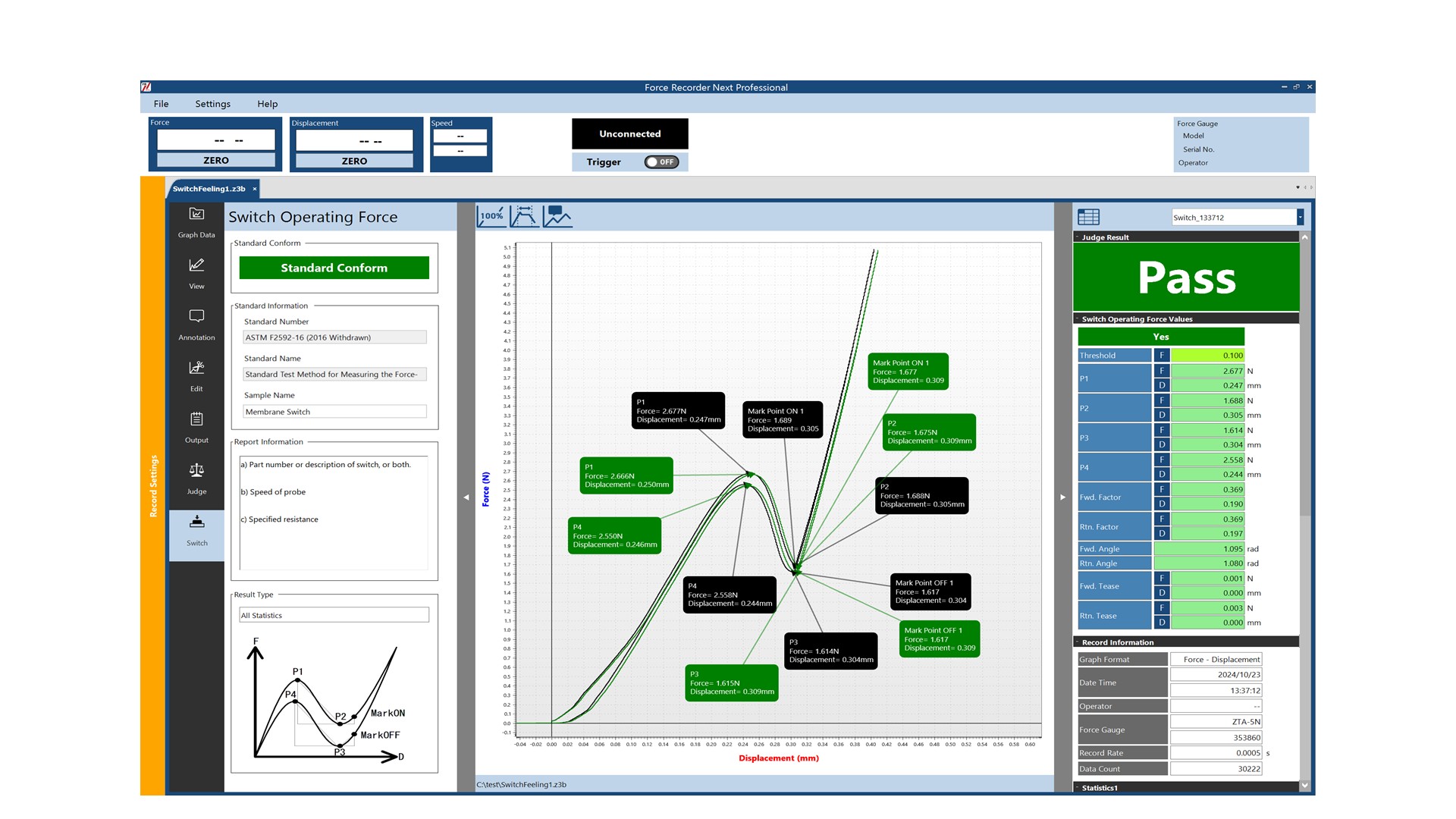

How Best to Draw Torque Graph

By graphing the torque measurement data, you can visually check the transition of torque values. The graph visualizes changes leading up to the peak and the detection of abnormal torque values such as foreign objects being caught, leading to more detailed confirmation of differences in physical characteristics and quality.

By creating graphs, you can also confirm the results at various change points visually, for example, the torque at which the cap begins to turn in a PET bottle screw cap test, or the torque when the bridge comes off the cap. The system is equipped with functions such as graph overlays and magnification, which are useful for result evaluation, making it easy to compare and verify results with past data.

PDF, CSV, and other printing options are provided, making it easy to create reports.

The software can be selected to suit the needs, such as one that acquires 2000 data/sec and create precise graphs, one that creates graphs together with angle data, and one that draws multiple graphs at the same time.

*Functions of software vary depending on the model. Check the specifications on the product page for details.

Click here to see the complete lineup of software.

List of all graphing software >

Check the below video for the torque graph drawing.

Draw Torque Graph

How Best to Connect with Angle Meter

By connecting angle meter with a torque tester equipped with an angle display function, you can input and output angles. By doing so, you can use the angle meter to evaluate the characteristics of materials and quality control that cannot be explained by torque alone. For example, the repulsive force of a material when it is twisted at a certain angle, or the operability of a rotating switch based on the correlation between torque and angle.

Two types exist:

1) an angle meter that can be built into a torque stand, and 2) an angle meter unit that can be connected to a handheld torque gauge. Using angle display software, a torque vs. angle graph can also be created.

*Check the specifications on the product page for details of applicable torque stand option or angle gauge unit .

Tips for More Effective Use of Torque Testers

Torque testers are equipped with useful functions.

The comparator function with high and low limit settings not only simplifies pass/fail test, but can also be interlocked with external devices to activate warning lights when defective or to control torque values using external outputs.

The mark point function records torque values at contact points such as rotary switches and displays them on a software graph.

With Next Series compatible products, you can upgrade your torque tester by downloading additional functions (see IMADA-Connected.com). Continuous peak mode and calibration date notification function are a few examples.

We offer guides for better use of torque testers, such as videos of various function settings and consultations for effective use. Contact us for more information.

*Specifications of torque gauges vary depending on the model. Check the specifications on the product page for details.

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

Friction Testing Module

Friction Testing Module

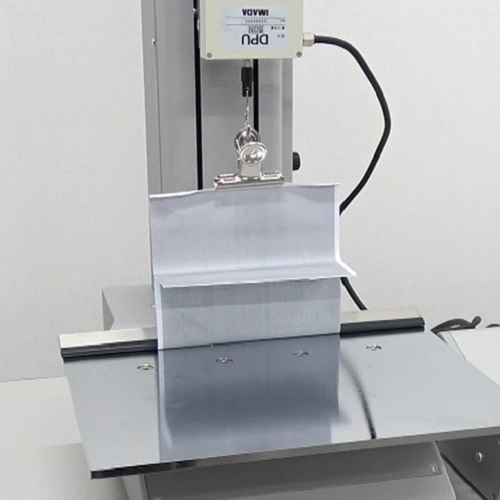

Peel Testing Module 1

Peel Testing Module 1

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

Multi-Peak Extraction Function

Multi-Peak Extraction Function

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

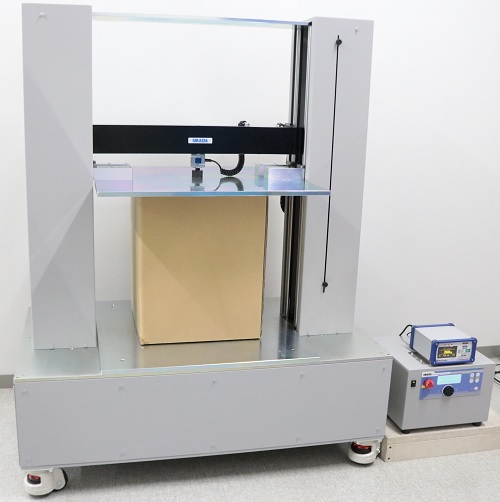

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

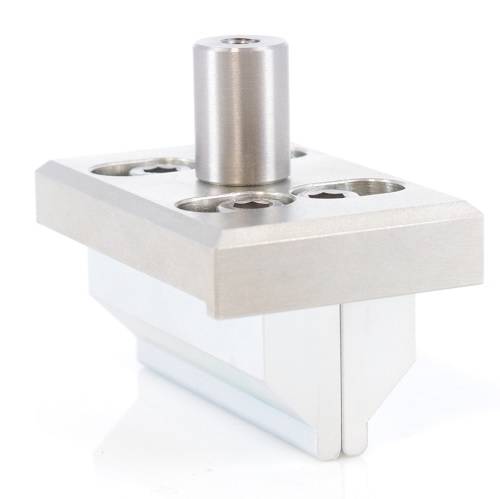

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

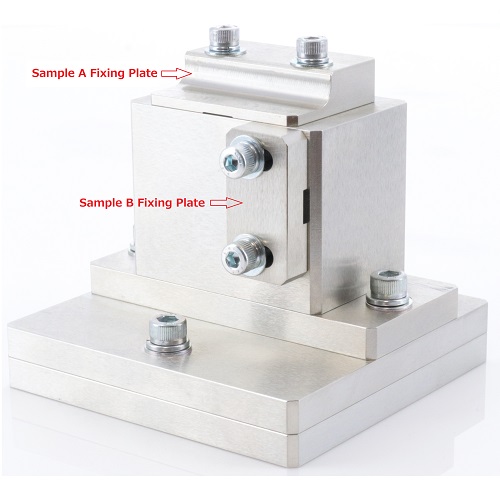

L-shaped Sample Fixture

L-shaped Sample Fixture

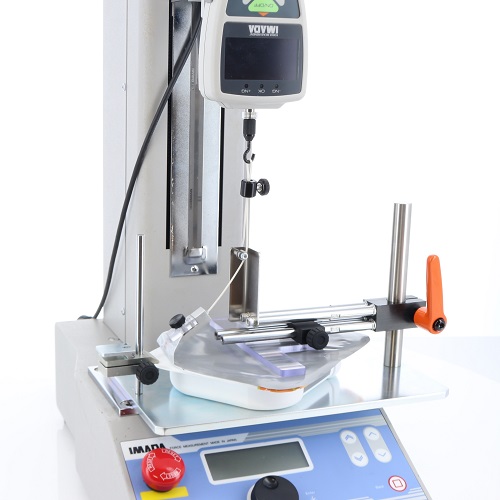

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

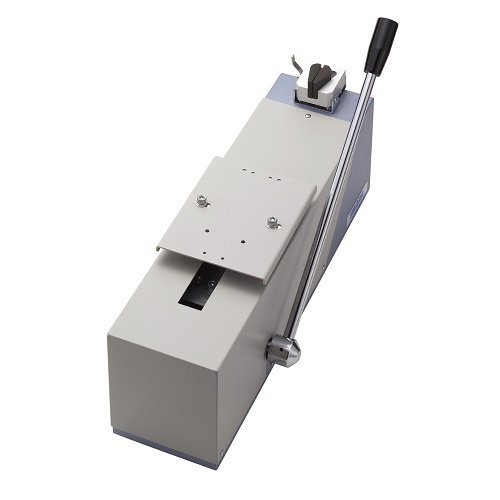

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

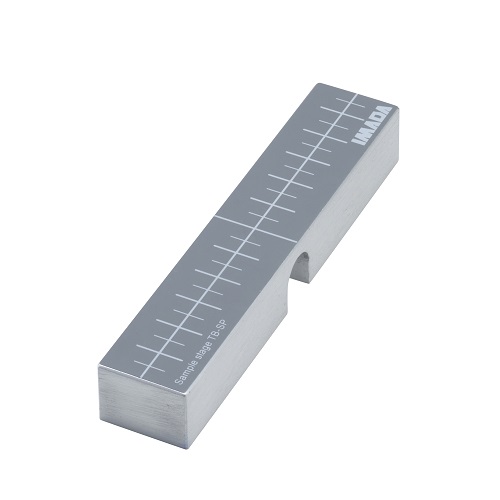

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

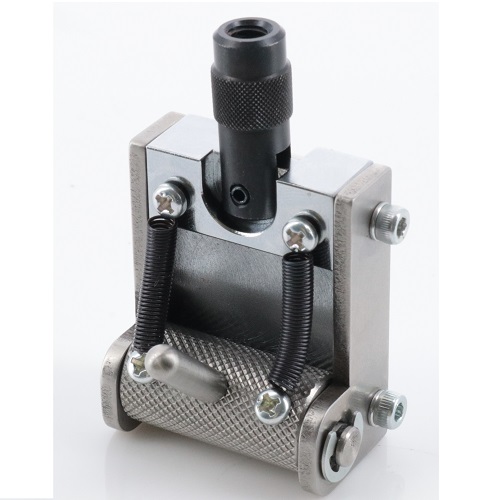

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

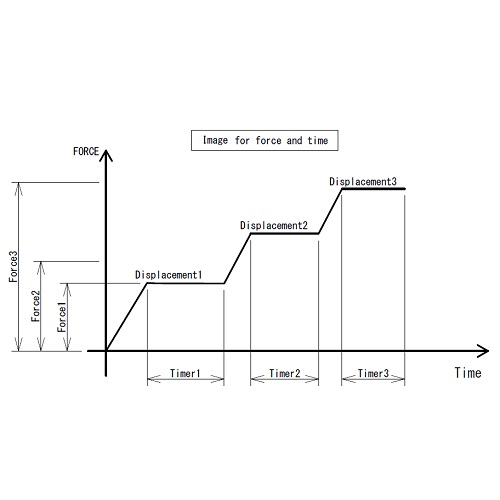

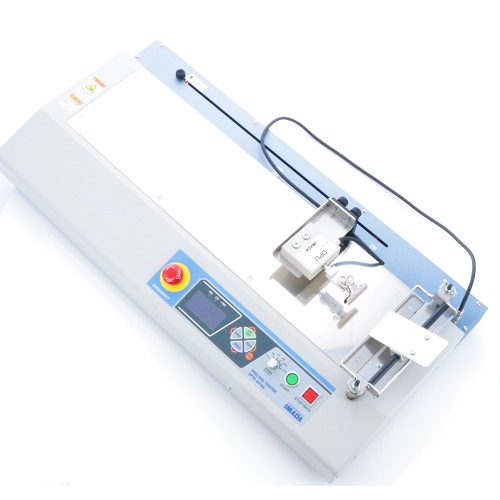

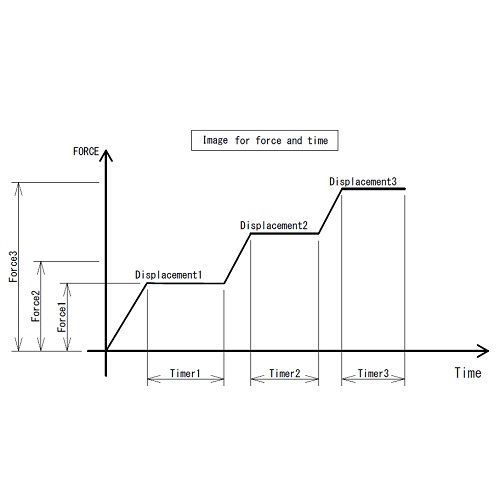

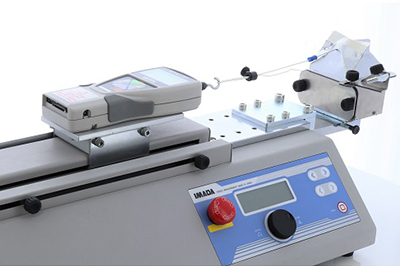

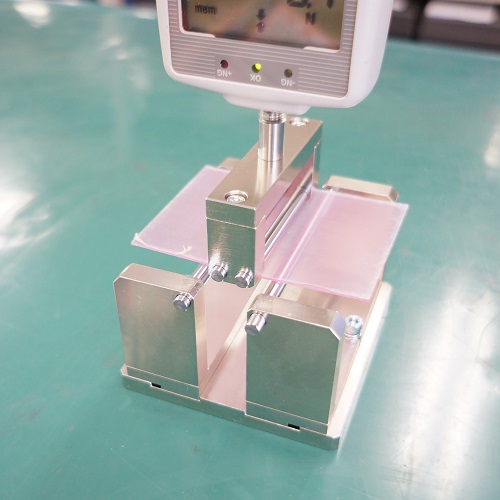

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

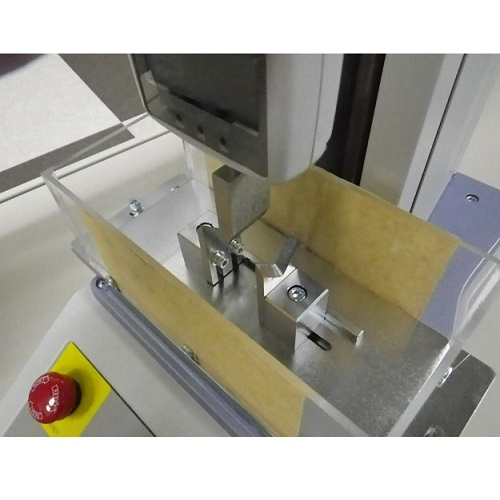

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

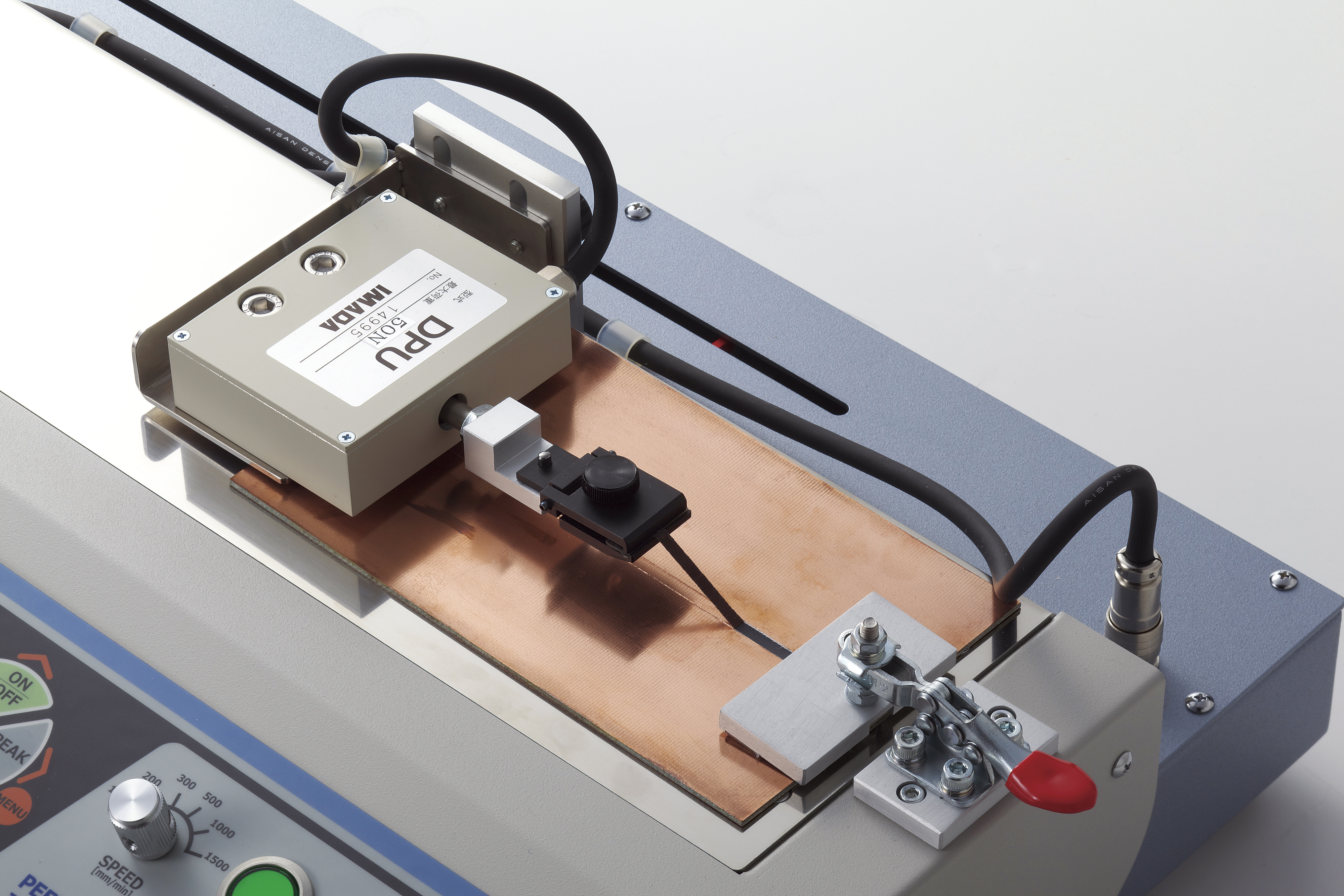

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)